Aug . 06, 2025 00:40 Back to list

Heavy-Duty American Type Welding Series Suspension

In the demanding world of heavy-duty transportation, the reliability of every component is paramount. The suspension system, the critical link between the chassis and the axles, bears the immense responsibility of ensuring stability, safety, and efficiency. This guide provides an in-depth exploration of the American Type Welding Series Suspension, a benchmark for durability and performance in the industry. We will delve into its technical specifications, manufacturing excellence, and real-world applications, demonstrating why it remains the top choice for fleet managers and operators who refuse to compromise on quality.

Industry Trends: The Drive for More Robust and Efficient Suspension Systems

The global logistics and transportation industry is evolving at an unprecedented pace. Key trends are shaping the design and selection of critical components like suspension systems. According to a 2023 report by MarketsandMarkets, the global semi-trailer market is projected to grow, driven by increasing freight volumes and the need for more efficient supply chains. This growth fuels a specific demand for suspension systems that offer:

- Higher Load Capacities: As economic pressures push for maximizing payload per trip, suspension systems must safely handle increased gross vehicle weights without compromising performance.

- Enhanced Durability & Longevity: Fleet operators are increasingly focused on Total Cost of Ownership (TCO). A suspension system that requires less maintenance and has a longer service life, such as the American Type Welding Series Suspension, offers significant long-term savings.

- Improved Fuel Efficiency: Modern suspension designs contribute to better aerodynamics and reduced rolling resistance. Even marginal gains in fuel efficiency translate to substantial savings across a large fleet.

- Adaptability to Diverse Terrains: From smooth interstate highways to rugged construction sites, trailers are expected to perform flawlessly. Suspension systems must be versatile enough to provide a stable ride and protect both the cargo and the vehicle in all conditions.

The American Type Welding Series Suspension is engineered to meet and exceed these modern demands, making it a forward-thinking investment for any serious transportation operation.

Core Technology: Unpacking the American Type Welding Series Suspension

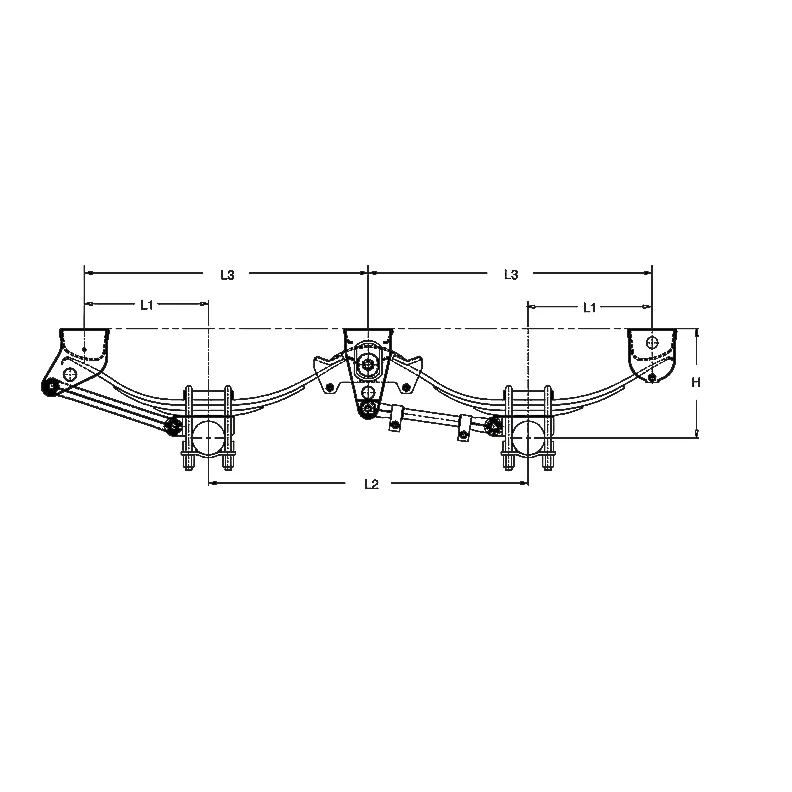

At its core, the American Type Welding Series Suspension is a mechanical marvel of engineering, designed for straightforward installation (weld-on), exceptional strength, and reliable service. Its design has been refined over decades to become an industry standard, particularly in North America. Let's break down its key components and technical parameters.

Detailed Technical Specifications

The following table outlines the typical specifications for our American Type Welding Series Suspension systems. Note that customization options are available to meet specific operational requirements.

| Parameter | Specification / Value | Industry Significance & Impact |

|---|---|---|

| Axle Capacity Range | 12T, 13T, 14T, 16T | Defines the maximum load the suspension is designed to support per axle. Higher capacity ensures safety for heavy-duty applications. |

| Suspension Type | Multi-Leaf Spring Mechanical Suspension | A proven, robust design known for its durability and load-sharing capabilities across rough terrain. Easy to maintain and repair. |

| Applicable Axle | 150mm Square Axle / 127mm Round Axle | Ensures compatibility with standard heavy-duty trailer axles used in the American market. |

| Leaf Spring Specs | Width: 90mm/100mm; Thickness: 13mm/16mm | These dimensions are critical for load-bearing capacity and fatigue resistance. Thicker, wider springs provide greater strength. |

| Number of Leaf Springs | 7, 8, 9, 10, 12, 14 (Customizable) | More leaves generally provide a higher spring rate and load capacity, tailored to specific cargo types. |

| Hanger Material | Q235 / Q345 High-Strength Steel | The hangers are the primary mounting points. Using high-strength steel (Q345 is equivalent to ASTM A572 Grade 50) is crucial for structural integrity. |

| Equalizer Material | Forged 45# Steel or High-Grade Ductile Iron | The equalizer beam distributes the load between axles, critical for stability. Forging provides superior strength and fatigue resistance over casting. |

| Bushing Type | Bi-metal / Rubber-Core / Polyurethane | Determines maintenance intervals and ride quality. Polyurethane offers a balance of durability and vibration damping. |

| Compliance Standards | ISO 9001:2015, ANSI/SAE Specifications | Certification and compliance guarantee that the product meets stringent international quality and safety benchmarks. |

From Raw Steel to Road-Ready: The Manufacturing Process Explained

The exceptional performance of the American Type Welding Series Suspension is not accidental; it is the direct result of a meticulous, quality-controlled manufacturing process that adheres to ISO 9001 standards. Each stage is designed to build in strength, precision, and longevity.

Our Manufacturing Workflow

1. Material Selection & Testing

High-tensile Q345 steel for structural parts and 45# forged steel for critical components are selected. Raw materials undergo spectroscopic analysis to verify composition and integrity.

2. Forging & Casting

Equalizers and torque arm heads are hot-forged to create a dense, uniform grain structure, maximizing strength. Hangers are precision cast or fabricated from high-strength plate.

3. CNC Machining

All critical mating surfaces and bushing holes are machined using CNC centers to achieve tight tolerances (within ±0.05mm), ensuring perfect alignment and component fit.

4. Welding & Assembly

Robotic welding arms are used for consistent, high-penetration welds on hanger assemblies. Manual assembly by certified technicians ensures all components, including pre-pressed bushings, are correctly installed.

5. Quality Control & Finishing

Each assembly undergoes a multi-point inspection, including dimensional checks and load testing. A final electrophoretic coating or powder coating provides superior corrosion resistance.

We exclusively use high-grade Q345 (yield strength ≥ 345MPa) steel for hangers and brackets, offering a significant strength advantage over common Q235 steel. This results in a system that can withstand higher dynamic loads without deformation.

Unlike cheaper cast alternatives, our equalizers are forged. This process aligns the steel's grain structure with the part's shape, eliminating internal voids and increasing fatigue life by up to 300% under strenuous testing conditions.

CNC machining ensures perfect alignment between the hangers, equalizer, and axle connection points. This precision minimizes tire wear, improves fuel economy, and prevents premature bushing failure—a common issue in lower-quality suspensions.

Our multi-stage finishing process, including shot blasting and an automotive-grade electrophoretic coating (E-coating), provides comprehensive protection against road salt, moisture, and chemicals, extending the service life well beyond industry norms.

Performance Metrics: A Data-Driven Comparison

To truly appreciate the engineering behind the American Type Welding Series Suspension, it's essential to look at the data. We've compiled performance metrics based on internal testing and industry benchmarks to visualize its advantages.

Durability Under Load (Fatigue Cycle Test)

Component Material Strength (Yield Strength in MPa)

The charts above illustrate two key points. The fatigue cycle test shows our American Type Welding Series Suspension endures significantly more load cycles before failure compared to generic market alternatives, a direct result of our superior forging and material selection. The material strength chart clearly shows the advantage of using Q345 steel and Forged 45# Steel for critical components, providing a higher safety margin and resistance to plastic deformation under extreme loads.

Application Scenarios & Customization

The versatility of the American Type Welding Series Suspension makes it the ideal choice for a wide range of heavy-duty applications. Its robust, simple design excels in environments where reliability is non-negotiable.

Primary Application Industries:

- Long-Haul Freight: For flatbed, dry van, and reefer trailers, its stability at highway speeds reduces tire wear and improves fuel efficiency, directly impacting profitability.

- Construction & Aggregates: On dump trailers and lowboys, its exceptional durability and load-sharing capability handle the uneven terrain and harsh shocks of job sites with ease.

- Logging & Forestry: The system's strength is crucial for safely transporting heavy, unevenly distributed loads of timber from remote and rugged locations.

- Tankers (Petrochemical & Liquid Transport): The stability provided by the mechanical leaf spring design helps to minimize fluid surge, enhancing safety during the transport of hazardous materials.

- Agriculture: Used on grain hoppers and equipment trailers, it provides a reliable and low-maintenance solution for seasonal, high-intensity use.

Application Case Study: Apex Logistics Inc.

"We switched our fleet of 200 flatbed trailers to the American Type Welding Series Suspension two years ago. We've seen a 40% reduction in suspension-related maintenance downtime and a noticeable improvement in tire longevity. The TCO analysis is overwhelmingly positive. These suspensions are built to last."

Tailored for Your Needs: Customization Solutions

We understand that one size does not fit all. Our engineering team works directly with clients to provide customized American Type Welding Series Suspension solutions. Customization options include:

- Custom Hanger Heights: To achieve specific ride heights for specialized trailers like drop-decks or car haulers.

- Variable Spring Configurations: Adjusting the number and thickness of leaves to fine-tune the spring rate for unique cargo types (e.g., sensitive electronics vs. raw steel).

- Specialized Bushing Materials: Offering options like bronze bushings for extreme-load, low-oscillation applications.

- Enhanced Coating Systems: For highly corrosive environments, such as coastal regions or chemical transport, we can apply specialized multi-layer coatings.

Contact our technical sales team to discuss your unique requirements and let us engineer the perfect suspension solution for your fleet.

Building Trust: Our Commitment to Quality and Support

Choosing a critical component like a suspension system is a decision built on trust. We earn that trust through transparency, third-party validation, and unwavering customer support.

Comprehensive Warranty

Our American Type Welding Series Suspension comes with a comprehensive 3-year / 300,000-mile limited warranty, covering defects in materials and workmanship for your peace of mind.

Guaranteed Delivery Cycle

With an optimized supply chain, we guarantee a standard production and delivery cycle of 4-6 weeks for standard orders, ensuring your operational timelines are met.

Dedicated Customer Support

Our expert technical support team is available 24/7 to assist with installation queries, parts identification, and troubleshooting, ensuring minimal downtime for your fleet.

ISO 9001:2015 Certified

Our manufacturing facilities are ISO 9001:2015 certified, a testament to our rigorous quality management systems and our commitment to continuous improvement and customer satisfaction.

Frequently Asked Questions (FAQ)

A weld-on suspension, like the American Type Welding Series Suspension, creates a permanent, monolithic bond with the trailer's frame or subframe. This offers superior structural integrity and rigidity, which is especially important for heavy-duty applications. While bolt-on suspensions offer easier replacement, welded suspensions eliminate the risk of bolts loosening over time due to vibration, providing a more reliable and maintenance-free connection point. Professional welding according to SAE standards is crucial for a safe installation.

The required axle capacity is determined by the Gross Axle Weight Rating (GAWR), which is the maximum distributed weight that can be supported by a single axle. You should consider the maximum weight of the cargo you intend to carry, plus the weight of the trailer itself, divided by the number of axles. It is always recommended to choose a suspension with a capacity that slightly exceeds your calculated maximum load to ensure a robust safety margin. Our technical team can assist you in calculating the correct capacity for your specific needs.

Q235 and Q345 are Chinese steel grades. The number refers to the minimum yield strength in megapascals (MPa). Q235 steel has a minimum yield strength of 235 MPa, while Q345 has a minimum yield strength of 345 MPa. This means Q345 is approximately 47% stronger than Q235. By using Q345 for our hangers and other structural parts of the American Type Welding Series Suspension, we provide a product that is significantly more resistant to bending and deformation under high stress, enhancing both safety and durability.

Inspection intervals depend heavily on the operating conditions and bushing material. For standard rubber-core bushings in long-haul applications, a visual inspection every 6 months or 50,000 miles is recommended. For more demanding off-road use, inspections should be more frequent. Replacement is necessary when you observe excessive wear, cracking, or "ovaling" of the bushing. Our premium polyurethane bushings offer a significantly longer service life and may only require inspection annually under normal conditions.

The equalizer (or equalizer beam) is a critical component in tandem or tri-axle suspension systems. It is the pivoting link between the leaf spring sets of adjacent axles. Its primary function is to distribute the load between the axles when the trailer encounters uneven surfaces. For example, when one axle goes over a bump, the equalizer pivots to transfer some of the load to the other axle, keeping tire contact with the ground and preventing dangerous load spikes on a single axle. This ensures a smoother ride, better traction, and improved braking stability.

While physically possible with significant modification, it is generally not recommended. American and European trailer designs have fundamental differences in frame width, ride height standards, and braking systems. The American Type Welding Series Suspension is specifically designed to integrate with the chassis and axle standards prevalent in North America. Mismatched components can lead to issues with alignment, stability, and regulatory compliance. We recommend consulting with a certified trailer engineer before attempting such a modification.

ISO 9001:2015 is an internationally recognized standard for Quality Management Systems (QMS). Our certification means that our manufacturing processes are consistently monitored, controlled, and audited by a third party. For you, the customer, it provides assurance that every American Type Welding Series Suspension we produce is subject to the same high standards of quality. It demonstrates our commitment to traceability, consistency, continuous improvement, and ultimately, delivering a product that is reliable, safe, and meets or exceeds your expectations.

Further Reading & Industry References

For those seeking to deepen their understanding of heavy-duty vehicle dynamics and component standards, we recommend the following authoritative resources:

- Society of Automotive Engineers (SAE International): "Truck and Bus Leaf Springs - SAE J510". A foundational standard for leaf spring design and testing. www.sae.org

- FleetOwner Magazine: An industry publication offering insights into vehicle maintenance, technology, and fleet management best practices. www.fleetowner.com/running-gear

- The Technology & Maintenance Council (TMC): A division of the American Trucking Associations that develops recommended practices for vehicle maintenance. Their "Recommended Practices Manual" is an invaluable resource. tmc.trucking.org

-

JOST TAPE Fifth Wheel 37C Repair Kits - Shijiazhuang Land Auto Component Ltd.

NewsAug.06,2025

-

JOST TAPE Fifth Wheel 37C Repair Kits-Premium Trailer Parts&Durable Fifth Wheel Repair Solutions

NewsAug.06,2025

-

Heavy-Duty American Type Welding Series Suspension

NewsAug.06,2025

-

JOST TAPE Fifth Wheel 37C Repair Kits- Shijiazhuang Land Auto Component Ltd.|Durability&Compatibility

NewsAug.05,2025

-

JOST TAPE Fifth Wheel 37C Repair Kits-Shijiazhuang Land Auto Component Ltd.|Durability&Compatibility

NewsAug.05,2025

-

Premium 5th Wheel Bumper Kit - Durable & Easy Install

NewsAug.05,2025