Јул . 28, 2025 16:52 Назад на списокот

Why Are Specialized Components Crucial in Commercial Vehicle Maintenance and Operation?

In the realm of heavy - duty transportation, the reliability and performance of commercial vehicles depend significantly on the quality and functionality of their components. From ensuring safe towing to optimizing operational efficiency, specific parts such as 3 piece wheel replacement parts, 3 axle 5th wheel, 24 slide, 18 wheeler fifth wheel hitch, and considerations for customer experience wheel play pivotal roles. Each of these elements addresses unique challenges in logistics, maintenance, and user satisfaction, making them indispensable for fleets and operators.

The Importance of 3 Piece Wheel Replacement Parts

In commercial vehicles, wheel systems are subjected to constant stress, making 3 piece wheel replacement parts vital for maintaining safety and durability. These parts, which typically include the rim, hub, and spokes, are designed to withstand the heavy loads and rough terrains common in logistics. For example, when a wheel sustains damage from a pothole or impact, replacing individual components with 3 piece wheel replacement parts allows for cost - effective repairs without replacing the entire wheel assembly. This modular design ensures that fleets can quickly restore functionality, minimizing downtime. Manufacturers often engineer these parts with corrosion - resistant materials, enhancing their lifespan even in harsh environments. Proper maintenance using high - quality 3 piece wheel replacement parts also improves tire performance, reducing the risk of blowouts and optimizing fuel efficiency.

Enhancing Towing Stability with 3 Axle 5th Wheel

A 3 axle 5th wheel is a critical component for heavy - duty trailers, particularly those transporting oversized or weighty cargo. The three - axle configuration distributes the load more evenly, reducing stress on the tractor and trailer. This setup enhances stability during turns and on uneven roads, a key factor in preventing accidents. For instance, in long - haul operations where trailers carry construction equipment or industrial machinery, a 3 axle 5th wheel ensures that the weight is balanced, improving maneuverability. The design of these fifth wheels often includes advanced locking mechanisms and wear - resistant surfaces, ensuring a secure connection between the tractor and trailer. Regular inspection and maintenance of the 3 axle 5th wheel are essential to prevent misalignment, which can lead to excessive vibration and potential damage to the vehicle’s frame.

Optimizing Space and Access with 24 Slide Systems

In recreational vehicles or commercial trailers, a 24 slide system revolutionizes interior space management. These slide - out mechanisms extend the living or storage area, creating more room for passengers or cargo. For example, in a 24 - foot trailer equipped with a 24 slide, the living space can expand significantly, enhancing comfort during long trips. The system operates smoothly, thanks to precision - engineered rails and bearings that withstand repeated use. Maintenance of the 24 slide involves lubricating moving parts and checking for alignment to ensure seamless operation. Proper installation and care of these slides prevent issues such as jamming or uneven extension, which could compromise the structural integrity of the trailer.

Securing Heavy Loads with 18 Wheeler Fifth Wheel Hitch

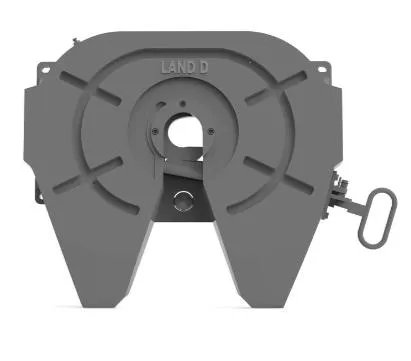

На 18 wheeler fifth wheel hitch is the backbone of the connection between a semi - tractor and its trailer. Designed to handle the immense weight and torque of an 18 - wheeler, these hitches feature robust construction and secure locking systems. For instance, when transporting goods across long distances, the 18 wheeler fifth wheel hitch must withstand constant vibrations and sudden stops, ensuring the trailer remains firmly attached. Manufacturers offer various models with different load capacities and adjustment options, allowing operators to choose the right hitch for their specific cargo. Regular maintenance, including greasing the pivot points and inspecting for wear, is crucial to prevent hitch failure, which could lead to dangerous accidents on the road.

Prioritizing User Satisfaction with Customer Experience Wheel

The concept of customer experience wheel in commercial vehicles focuses on designing components that meet the needs and expectations of operators and fleet managers. This includes aspects such as ease of maintenance, durability, and access to support services. For example, manufacturers that offer 3 piece wheel replacement parts with clear installation guides enhance the customer experience by reducing the time and effort required for repairs. Similarly, a 3 axle 5th wheel with intuitive adjustment features allows mechanics to perform maintenance more efficiently, improving overall fleet productivity. The customer experience wheel also involves post - sale support, such as readily available replacement parts and technical assistance, which build trust and loyalty among customers.

FAQ: Key Insights into Commercial Vehicle Components

How do I choose the right 3 piece wheel replacement parts for my fleet?

Selecting 3 piece wheel replacement parts requires matching the vehicle’s specifications, such as load capacity, wheel size, and material compatibility. Consult the manufacturer’s guidelines to ensure the parts meet safety standards. Prioritize components with anti - corrosion coatings for longevity, especially if the fleet operates in harsh climates. Comparing prices and warranties from reputable suppliers can help balance cost and quality, ensuring reliable performance.

What maintenance is required for a 3 axle 5th wheel?

Regularly inspect the 3 axle 5th wheel for wear on the locking mechanism, pivot points, and surface coatings. Lubricate moving parts according to the manufacturer’s schedule to prevent friction and corrosion. Check for proper alignment to avoid uneven load distribution, which can cause excessive wear on the tractor and trailer. Address any signs of damage, such as cracks or excessive play, immediately to maintain towing safety.

Can a 24 slide system be retrofitted into an older trailer?

Yes, many 24 slide systems are designed for retrofitting, but it requires assessing the trailer’s structural compatibility. Consult a professional installer to evaluate the trailer’s frame strength and available space. Ensure the slide system’s weight capacity matches the intended use, whether for expanding living quarters or increasing cargo space. Proper installation by experienced technicians is essential to guarantee smooth operation and structural integrity.

What factors determine the load capacity of an 18 wheeler fifth wheel hitch?

The load capacity of an 18 wheeler fifth wheel hitch is determined by its design, material strength, and manufacturing standards. Key factors include the hitch’s gross combined weight rating (GCWR), which accounts for the tractor and trailer’s total weight. Additionally, the hitch’s vertical load capacity (weight on the tractor’s rear axle) and horizontal towing capacity (pulling force) must align with the vehicle’s specifications. Always refer to the manufacturer’s data to ensure the hitch is rated for the intended cargo weight.

How does the customer experience wheel impact fleet management?

На customer experience wheel influences fleet management by prioritizing components that reduce downtime and operational costs. For example, easy - to - maintain parts like 3 piece wheel replacement parts or user - friendly 18 wheeler fifth wheel hitches with clear adjustment procedures enhance efficiency. Good customer experience also includes access to quick technical support and genuine replacement parts, which minimize delays in repairs and keep fleets operational. Investing in components that align with the customer experience wheel ultimately improves productivity and reduces long - term maintenance expenses.

-

Why Are Specialized Components Crucial in Commercial Vehicle Maintenance and Operation?

ВестиJul.28,2025

-

Why Are Fifth Wheels Critical for Trucking and How to Select the Right One?

ВестиJul.28,2025

-

What Defines the Excellence of American Trailer Components in Key Markets?

ВестиJul.28,2025

-

What Defines the Excellence of American 5th Wheel Systems and Their Market Offerings?

ВестиJul.28,2025

-

How Do 5th Wheel Trailers Redefine Towing and Living Standards?

ВестиJul.28,2025

-

How Do 5th Wheel Systems Enhance Commercial Hauling Efficiency and Versatility?

ВестиJul.28,2025