Ogo . 24, 2025 00:20 Back to list

Heavy-Duty 5th Wheel Hitch for Sale - Secure Your Towing!

Strategic Sourcing of Fifth Wheel Hitches for Heavy-Duty Transport

In the demanding world of commercial trucking and logistics, the reliability and performance of 5th wheel hitch for sale are paramount. These critical components, integral to any truck trailer components setup, form the essential link between a tractor and its semi-trailer, facilitating safe and efficient heavy cargo transport. This comprehensive guide delves into the technical intricacies, industry applications, and strategic considerations for selecting high-performance fifth wheel hitches, with a focus on models engineered for extreme durability and operational efficiency.

Modern heavy duty 5th wheel hitch systems are not merely coupling devices; they are sophisticated mechanical assemblies designed to withstand immense dynamic loads, ensure precise trailer steering system control, and contribute to overall vehicle stability and fuel efficiency. As the industry evolves, driven by stricter safety regulations and increasing demands for payload capacity, understanding the manufacturing excellence and performance benchmarks of these components becomes crucial for procurement specialists and fleet managers.

Industry Trends and Market Dynamics for Fifth Wheel Hitches

The market for 5th wheel hitch for sale is characterized by continuous innovation aimed at enhancing safety, reducing weight, and improving longevity. Key trends include the adoption of advanced materials, such as high-strength low-alloy (HSLA) steels and optimized cast irons, to achieve superior strength-to-weight ratios. Furthermore, integrated sensor technologies for real-time coupling status and load distribution monitoring are gaining traction, providing operators with enhanced situational awareness and predictive maintenance capabilities.

- Lightweighting: Manufacturers are exploring composite materials and design optimizations to reduce overall vehicle weight, contributing to improved fuel economy and increased payload capacity without compromising structural integrity.

- Enhanced Safety Features: Automatic locking mechanisms, visual and audible coupling indicators, and advanced anti-slack systems are becoming standard, minimizing the risk of accidental uncoupling.

- Smart Integration: Telematics-ready fifth wheels that can communicate vital operational data to fleet management systems are emerging, facilitating better asset utilization and maintenance scheduling.

- Durability and Service Life: Focus on robust designs and superior corrosion protection to extend the operational life of 5th wheel hitch parts in harsh environments.

The demand for robust truck trailer components continues to grow, particularly in sectors such as long-haul logistics, construction, and specialized transport. This growth fuels innovation in all related segments, including advanced trailer steering system solutions and superior heavy duty 5th wheel hitch designs.

Manufacturing Process Flow for High-Performance Fifth Wheel Hitches

The production of a high-quality 5th wheel hitch for sale involves a meticulously controlled multi-stage process, ensuring precision, strength, and durability. Here's a generalized overview, emphasizing the manufacturing of cast top plate hitches like the Fifth wheel 38C:

Process Schematic:

- Material Selection & Preparation: High-grade alloy steel (e.g., ASTM A148 Grade 90-60 or equivalent for casting) is selected for its superior tensile strength and fatigue resistance. Raw materials are inspected for quality and composition.

-

Casting (for top plate): Precision casting processes create the complex geometry of the fifth wheel top plate. This involves melting the alloy steel and pouring it into molds. This method allows for intricate designs that optimize stress distribution.

- Example: Sand casting or investment casting techniques are employed to ensure minimal defects and optimal surface finish.

- Forging (for jaw and locking mechanisms): Critical components like the locking jaws and operating handle are often forged to achieve maximum density and grain structure integrity, enhancing their resistance to wear and impact.

- CNC Machining: Cast and forged parts undergo precise CNC machining to achieve tight tolerances for critical mating surfaces, pin holes, and articulation points. This ensures smooth operation and proper fitment of 5th wheel hitch parts.

- Heat Treatment: Components are heat-treated (e.g., quenching and tempering) to achieve the desired hardness, toughness, and fatigue strength, crucial for heavy duty 5th wheel hitch applications.

- Surface Treatment & Corrosion Protection: Shot blasting, priming, and powder coating (or other durable finishes like e-coating) are applied to provide superior corrosion resistance, extending the service life, particularly in environments like petrochemical or coastal areas.

- Assembly: Sub-assemblies (e.g., locking mechanism, mounting brackets) are integrated with the top plate and base. Precision fasteners are used, and torque specifications are strictly followed.

-

Quality Control & Testing: Each unit undergoes rigorous testing.

- Non-Destructive Testing (NDT): Ultrasonic, magnetic particle, or radiographic inspection for internal defects.

- Load Testing: Static and dynamic load tests to simulate real-world operating conditions and verify performance against specified capacities (e.g., D-value, V-value).

- Fatigue Testing: Accelerated life cycle testing to predict service life under repetitive stress.

- Compliance: Verification against international standards such as ISO 3842 (Road vehicles – Fifth wheels – Interchangeability) and ANSI/SAE J2227 (Fifth Wheel Kingpin and Fifth Wheel Coupling Performance).

- Packaging & Shipping: Finished products are prepared for transport, often with protective coatings or covers.

This meticulous process ensures that each 5th wheel hitch for sale meets the highest standards of safety, performance, and longevity, often exceeding typical service life expectations of 5-7 years in demanding applications. Target industries benefiting from such robust manufacturing include petrochemical, metallurgy, water supply & drainage, construction, and specialized heavy haulage. The advantages in these scenarios are clear: enhanced safety, reduced maintenance costs, and superior corrosion resistance leading to reliable operation even in aggressive chemical or high-humidity environments.

Technical Specifications and Performance Parameters

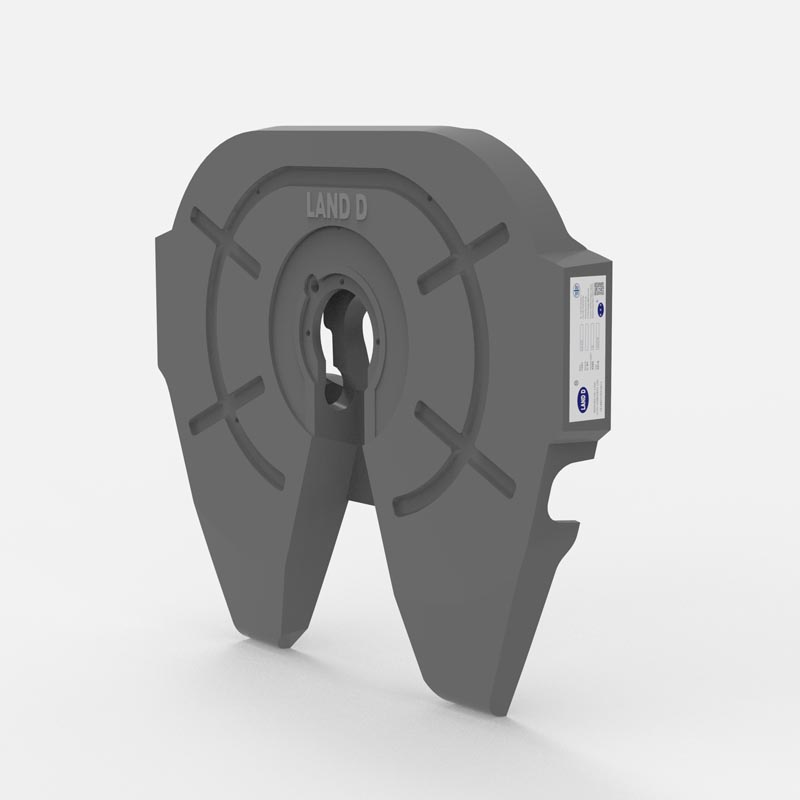

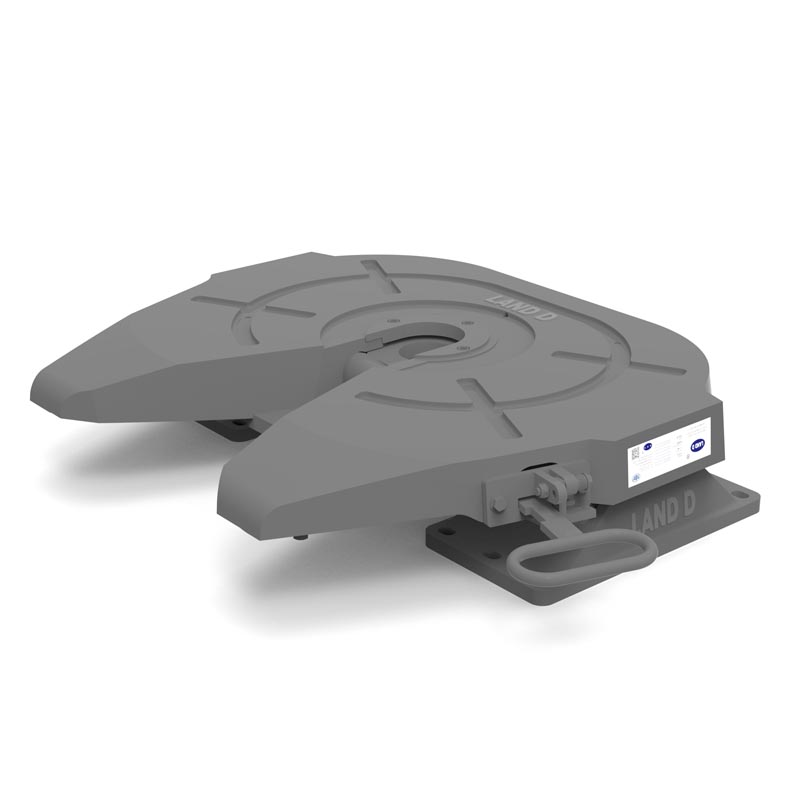

Understanding the technical specifications of a 5th wheel hitch for sale is vital for proper application matching and ensuring compliance with regulatory requirements. The Fifth wheel 38C Cast top plate-trailer truck parts Hitch Heavy Duty Hitch exemplifies modern engineering in this category.

Product Specification Table: Fifth wheel 38C Cast Top Plate Hitch

| Parameter | Value/Description |

|---|---|

| Product Name | Fifth wheel 38C Cast top plate-trailer truck parts Hitch Heavy Duty Hitch |

| Type | Cast Top Plate, Standard Duty to Heavy Duty |

| Max. Vertical Load (U-value) | 18,000 kg (Approximately 39,683 lbs) |

| Max. D-Value (Coupling Force) | 152 kN (Approximately 34,170 lbf) |

| Kingpin Size Compatibility | 2-inch (50mm) per ISO 3842 |

| Mounting Height Range | Standard adjustable ranges, typically 150mm to 300mm+ |

| Material | High-strength alloy cast steel |

| Weight (Approx.) | ~140-160 kg (model dependent) |

| Compliance | ISO 3842, Q-MARK (where applicable) |

| Applications | On-highway haulage, construction, special transport |

The D-value (Dynamic Value) is a critical performance metric, representing the maximum horizontal force the fifth wheel can withstand under dynamic braking and acceleration. A higher D-value indicates superior robustness for managing extreme longitudinal forces. The U-value (Vertical Load) specifies the maximum permissible static load on the fifth wheel, directly influencing the permissible gross vehicle weight. These parameters are essential when considering any heavy duty 5th wheel hitch.

Application Scenarios and Technical Advantages

The versatility of robust 5th wheel hitch for sale ensures their applicability across a broad spectrum of industries, each benefiting from specific technical advantages. The Fifth wheel 38C, for instance, is engineered to excel in demanding environments.

- Long-Haul Logistics: High vertical and D-values ensure stable coupling for heavy articulated vehicles traversing varying terrains and speeds. The smooth articulation contributes to driver comfort and reduced tire wear, optimizing overall fleet operational costs.

- Construction & Heavy Equipment Transport: Ideal for transporting excavators, cranes, and modular components. The robust cast steel construction of the 38C provides the necessary strength to withstand shock loads associated with rough construction sites and uneven roads.

- Petrochemical Industry: Specialized corrosion-resistant coatings applied during manufacturing are crucial for longevity in environments exposed to corrosive chemicals or saltwater, demonstrating significant advantages in service life and reducing maintenance downtime.

- Mining & Metallurgy: In these sectors, equipment often faces extreme dust, grime, and heavy, continuous use. A heavy duty 5th wheel hitch with sealed lubrication points and robust construction minimizes ingress of contaminants, ensuring reliable operation.

- Water Supply & Drainage Infrastructure: Transporting large pipes, pumps, and treatment modules requires stable, secure coupling. The precise trailer steering system facilitated by quality fifth wheel hitches ensures maneuverability in urban and constrained environments.

A primary technical advantage is the "energy saving" aspect, often overlooked. A well-designed fifth wheel, with optimized friction characteristics and precise kingpin engagement, reduces drag and unnecessary movement between the tractor and trailer. This subtle improvement, across a large fleet, can lead to measurable fuel efficiency gains. Furthermore, the inherent corrosion resistance from superior surface treatments extends the life of the entire truck trailer components system, deferring replacement costs and minimizing downtime for repairs.

Vendor Comparison and Strategic Procurement

When evaluating suppliers for a 5th wheel hitch for sale, fleet operators and procurement managers must consider a holistic set of criteria beyond initial cost. The long-term total cost of ownership (TCO) is heavily influenced by product quality, after-sales support, and innovation.

Fifth Wheel Hitch Vendor Comparison Criteria

| Criterion | High-Tier Vendor (e.g., landfifthwheel.com) | Standard Vendor |

|---|---|---|

| Material Quality | Certified high-strength alloy steels, advanced casting/forging. | Standard carbon steel, basic casting. |

| Manufacturing Process | Precision CNC machining, robotic welding, multi-stage QC. | Basic machining, manual welding, less stringent QC. |

| Testing & Certification | ISO 9001, ISO 3842, rigorous internal load/fatigue testing, Q-MARK. | Basic safety compliance, limited specific certifications. |

| Durability & Service Life | Designed for extended service life (7+ years), superior corrosion protection. | Typical 3-5 year lifespan, basic paint finish. |

| Technical Support | Comprehensive documentation, expert consultation, global network. | Limited documentation, basic troubleshooting. |

| Customization Options | Extensive options for mounting, materials, and features. | Minimal to no customization available. |

An authoritative supplier will provide detailed test data and certifications (e.g., ISO 9001 for quality management, ISO 3842 for interchangeability), demonstrating their commitment to quality. Companies with decades of experience and a strong client roster, including major OEM partners, offer greater assurance of reliability for your truck trailer components needs.

Customized Solutions and Tailored Engineering

While standard heavy duty 5th wheel hitch models meet most requirements, specialized applications often necessitate customized solutions. Experienced manufacturers can provide bespoke engineering services for unique operational challenges. This might include:

- Non-Standard Mounting Heights: For specialized trailers or vehicle chassis.

- Alternative Materials: For extreme temperatures, chemical exposure, or weight-saving mandates.

- Integrated Sensors: Custom integration of load cells, coupling sensors, or temperature monitors for enhanced telemetry.

- Specialized Lubrication Systems: For reduced maintenance in inaccessible or highly demanding environments.

- Custom Finishes: Beyond standard powder coating, such as military-grade or marine-grade protective layers.

Engaging with a vendor offering flexible manufacturing capabilities and a strong engineering department ensures that even the most complex requirements for 5th wheel hitch parts can be met with precision and confidence, ensuring optimal performance of your trailer steering system.

Application Case Studies & Customer Experience

Real-world application demonstrates the efficacy and reliability of a premium 5th wheel hitch for sale. Here are anonymized examples reflecting common scenarios:

Case Study 1: Harsh Climate Freight Operations

A major freight company operating in regions with severe winter conditions and high road salt usage faced premature corrosion and fatigue failures of their standard fifth wheels. Upon switching to a manufacturer providing the Fifth wheel 38C with advanced e-coating and hardened components, they observed a 40% reduction in fifth wheel-related maintenance costs over two years. The enhanced corrosion resistance and robust design significantly extended component life in their critical truck trailer components.

Case Study 2: Oversize Load Transport Specialist

A specialized hauler frequently transporting multi-axle trailers with loads exceeding 100,000 lbs required a heavy duty 5th wheel hitch with exceptional D-value and articulation. Partnering with a supplier capable of custom engineering, they received a reinforced fifth wheel with integrated wear plates and a self-lubricating system. This solution provided superior stability and maneuverability, especially critical when navigating tight turns with a complex trailer steering system. Customer feedback highlighted improved driver confidence and reduced wear on associated kingpins.

Case Study 3: Global Logistics Fleet Modernization

A large global logistics provider sought to standardize their fleet with highly reliable 5th wheel hitch parts. After an extensive evaluation period and a trial program involving several manufacturers, they selected a vendor known for its ISO-certified processes and comprehensive warranty. The decision was based on superior fatigue test results, consistent product quality, and a commitment to global parts availability, ensuring operational continuity across diverse geographical locations.

These cases underscore the tangible benefits of investing in high-quality, expertly manufactured fifth wheel hitches: reduced operational costs, enhanced safety, and prolonged asset life.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

Building trust in the B2B sector for 5th wheel hitch for sale is not just about product specifications; it's also about clear communication on logistics, guarantees, and support.

Frequently Asked Questions (FAQ)

Q1: What is the typical lead time for a bulk order of Fifth wheel 38C hitches?

A1: Standard bulk orders for the Fifth wheel 38C typically have a lead time of 4-6 weeks, depending on order volume and current production schedule. Customized solutions or very large orders may require longer, which will be communicated clearly during the quotation phase.

Q2: What is the warranty period for your heavy duty 5th wheel hitch products?

A2: We offer a comprehensive 1-year warranty on materials and workmanship for all our heavy duty 5th wheel hitch products, including the Fifth wheel 38C. Extended warranty options may be available upon request for specific fleet agreements.

Q3: Do you provide technical support for installation and maintenance?

A3: Yes, our dedicated technical support team is available to assist with installation guidelines, maintenance best practices, and troubleshooting for all our 5th wheel hitch parts. We provide detailed manuals and can arrange virtual or on-site support for major fleet deployments.

Q4: Are your fifth wheel hitches certified to international standards?

A4: Absolutely. Our manufacturing processes are ISO 9001 certified, and our fifth wheel hitches, including the Fifth wheel 38C, comply with ISO 3842 (Road vehicles – Fifth wheels – Interchangeability). We also adhere to regional certifications as required for various markets.

Lead Time & Fulfillment

We maintain a streamlined production and supply chain to ensure efficient fulfillment. For standard configurations of 5th wheel hitch for sale, lead times are optimized to minimize disruption to your operations. For urgent requirements or bespoke solutions, we work closely with clients to establish realistic and achievable delivery schedules. Our logistics partners ensure secure and timely global delivery.

Warranty Commitments

Our warranty covers defects in materials and workmanship, reflecting our confidence in the quality and durability of our truck trailer components. This commitment ensures peace of mind and safeguards your investment, underpinning our promise of reliability for every heavy duty 5th wheel hitch we supply.

Customer Support Information

Our dedicated customer support team is available via phone, email, or online portal for technical inquiries, order status, and after-sales assistance. We strive to provide prompt and expert responses, ensuring that your fleet remains operational and efficient. Detailed contact information is available on our corporate website.

Conclusion

The selection of a premium 5th wheel hitch for sale is a critical decision that impacts fleet safety, operational efficiency, and long-term cost of ownership. By prioritizing manufacturers who adhere to rigorous engineering standards, employ advanced manufacturing processes, and offer comprehensive support, B2B decision-makers can ensure they equip their fleets with the most reliable and performance-driven truck trailer components available. The Fifth wheel 38C Cast top plate-trailer truck parts Hitch Heavy Duty Hitch exemplifies the commitment to quality, durability, and innovation required in today's demanding transport industry.

References

- International Organization for Standardization. ISO 3842:2016 - Road vehicles — Fifth wheels — Interchangeability.

- SAE International. SAE J2227: Fifth Wheel Kingpin and Fifth Wheel Coupling Performance.

- ASTM International. ASTM A148/A148M-17: Standard Specification for Steel Castings, High-Strength, for Structural Purposes.

- Transportation Research Board. The National Academies of Sciences, Engineering, and Medicine. Improving Freight System Performance.

- Federal Motor Carrier Safety Administration (FMCSA). Code of Federal Regulations, Title 49, Part 393 - Parts and Accessories Necessary for Safe Operation.

-

Heavy-Duty 5th Wheel Hitch for Sale - Secure Your Towing!

NewsAug.24,2025

-

Durable Germany Type Suspension for Heavy Duty Trucks & Trailers

NewsAug.23,2025

-

American Type Welding Suspension Series: Strong, Reliable Hooks

NewsAug.22,2025

-

Hezhen 1-3mm Luminous Stone- Shijiazhuang Land Auto Component Ltd.|Durability&High Luminosity

NewsAug.18,2025

-

Hezhen 1-3mm Luminous Stone - Shijiazhuang Land Auto Component Ltd.

NewsAug.18,2025

-

Hezhen 1-3mm Luminous Stone - Shijiazhuang Land Auto Component Ltd.|Durable & Versatile

NewsAug.18,2025