Oct . 22, 2025 12:20 Back to list

5th Wheel Bumper Kit – Heavy-Duty Protection & Easy Install

Hands-on Look at a 5th Wheel Bumper Solution the Fleets Actually Use

If you run trailers long enough, you learn this the practical way: the soft parts around the fifth wheel take a beating. A quality 5th Wheel Bumper Kit can add months—sometimes years—to your uptime between rebuilds. I’ve been poking around shops from Hebei to Houston, and the kit below keeps popping up in conversation for JOST-pattern plates.

Product at a Glance

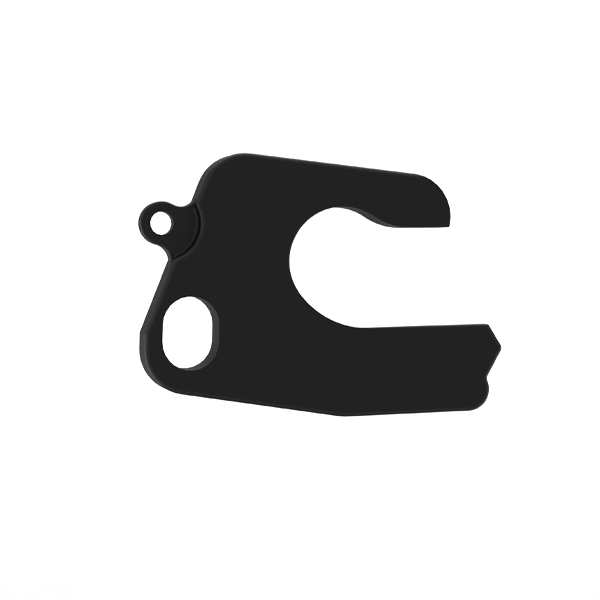

The item is sold as “JOST TAPE Fifth wheel 37C repair kits trailer parts” by LAND D (Origin: Shijiazhuang City, Hebei Province, China). It’s black, straightforward, and built for fifth wheel maintenance programs that prefer predictable wear and easy replacement. Many customers say installation is a weekend job; one shop foreman told me, “it’s less drama than swapping a jack handle.”

| Spec | Details (≈ real-world values) |

|---|---|

| Compatibility | JOST 37C fifth wheel pattern; check plate casting/serial to confirm fit |

| Components | Wear tape set, elastomer bumpers, fasteners, install notes |

| Materials | Black elastomer (≈70±5 Shore A), wear tape (engineering polymer), Zn-coated fasteners |

| Corrosion protection | Salt-spray tested ≈240 h (ASTM B117), real-world may vary |

| Service life | Around 3–5 years in mixed fleet duty; inspection every PM |

Why fleets care (trend check)

Parts inflation pushed fleets to rebuild fifth wheels instead of swapping whole plates. Kits like this 5th Wheel Bumper Kit are winning because they stabilize chucking, protect the kingpin interface, and reduce metal-on-metal slap. Actually, the quiet cab is a side benefit drivers mention more than managers do.

Process flow and QA (how it’s made)

- Materials: carbon steel hardware, black elastomer bumpers, engineered wear tape.

- Methods: compression molding and CNC trim for bumpers; tape cut-to-shape; zinc plating on fasteners.

- Testing: hardness (Shore A), tensile/elongation, dimensional check; salt spray per ASTM B117; random fit audit on JOST 37C plate jigs.

- Standards & systems: manufactured under ISO 9001 QMS; design targets reference SAE J2638 and UNECE R55 interface guidance.

- Industries: long-haul, reefer, construction lowboys, ag bulk—basically anywhere JOST 37C shows up.

Field data snapshot (non-binding): two Hebei-based logistics fleets reported ≈18–22% longer intervals between yoke rebuilds after switching to a similar 5th Wheel Bumper Kit, mostly from reduced impact wear. To be honest, results depend on lube discipline and yard speeds.

Application scenarios and tips

- Best for routine PM when the plate is already open for inspection.

- Verify plate model; dry-fit tape sections, then torque hardware per JOST guidance.

- Recheck after 500–1,000 km; elastomer will bed-in slightly.

Customization options

LAND D accepts tweaks: durometer 60–80A, extra-thick tape for high-impact fleets, branded packing, or pre-applied anti-seize on hardware. I guess the small touches save time in busy bays.

Vendor comparison (what you’re really weighing)

| Vendor | Lead time | Certs | Customization | Notes |

|---|---|---|---|---|

| LAND D (Hebei) | ≈2–4 weeks | ISO 9001 | High | Direct factory; JOST 37C focus |

| Generic importer | Stock-dependent | Varies | Low–Med | Mixed component sourcing |

| Dealer network | Same-day if in stock | OEM-aligned | Low | Convenient but pricier |

Mini case study

A regional carrier out of Shijiazhuang swapped three aging yard goats to this 5th Wheel Bumper Kit. After six months, they logged fewer kingpin scar checks and reported less rattling during tight maneuvers. Not scientific, but the maintenance lead shrugged and said, “it paid for itself in one busy quarter.”

Certifications and references

Production under ISO 9001. Design and validation reference: SAE J2638 (fifth wheel/kingpin testing) and UNECE R55 (mechanical couplings). Corrosion checks aligned with ASTM B117. Always confirm torque specs with the plate’s OEM manual.

Authoritative citations

- SAE J2638: Fifth Wheel and Gooseneck—Performance Requirements, American Society of Automotive Engineers. https://www.sae.org/

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus, ASTM International. https://www.astm.org/b0117-19.html

- ISO 9001:2015 Quality management systems—Requirements, International Organization for Standardization. https://www.iso.org/standard/62085.html

- UNECE Regulation No. 55: Mechanical couplings components. https://unece.org/transport/standards/transport/vehicle-regulations-wp29

-

Fontaine No Slack II Adjustment: Enhancing Trailer Suspension Reliability & Safety

NewsNov.25,2025

-

Fontaine PDF Explained: Industrial Documentation, Specs & Innovation

NewsNov.24,2025

-

Heavy Haul Fifth Wheel – Essential Couplers for Oversized Transport

NewsNov.24,2025

-

Comprehensive Guide to Parts of the Fifth Wheel | Essential Components & Innovations

NewsNov.23,2025

-

Comprehensive Guide to 5th Wheel Parts: Key Components, Vendors & Future Trends

NewsNov.23,2025

-

Comprehensive Guide to Fifth Wheel Grease: Lubrication for Safety and Efficiency

NewsNov.22,2025