Oct . 23, 2025 11:35 Back to list

Semi Trailer Kingpin Plate Replacement | Durable, OEM-Grade

Semi Trailer Kingpin Plate Replacement: field notes from real fleets

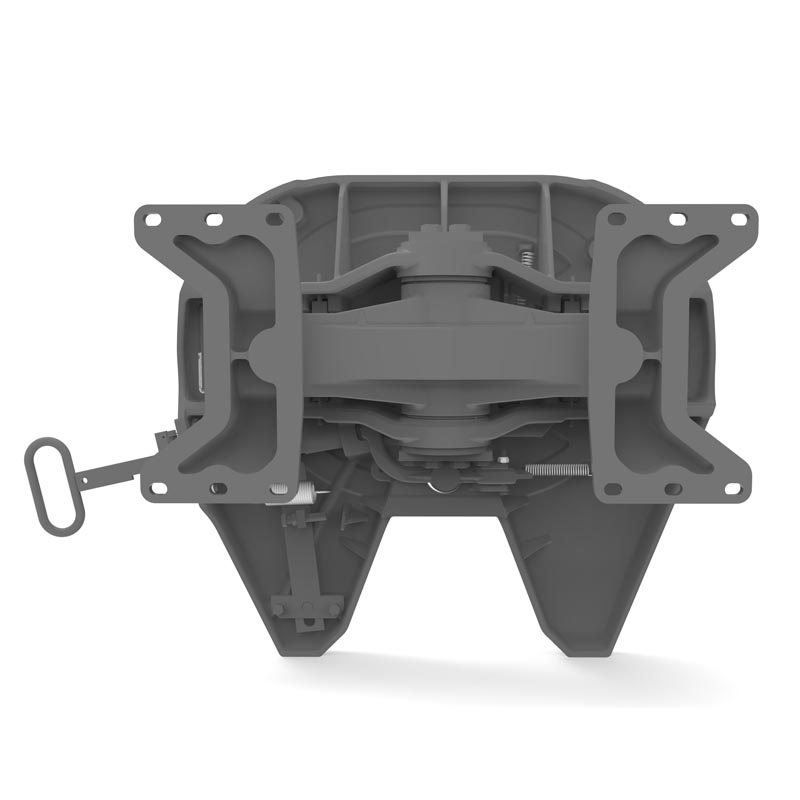

If you’re planning a Semi Trailer Kingpin Plate Replacement, it’s smart to evaluate the fifth wheel at the same time—because the upper coupler and the coupling device live and die together. The Fifth wheel J-3800 from Shijiazhuang, Hebei, has been popping up a lot in my notes lately—ultra-large tonnage capacity, four-way swing, and, to be honest, better manners on rough yards than I expected.

Why it matters when you touch the kingpin plate

The kingpin plate (upper coupler) takes the brunt of impact loads; the fifth wheel distributes them into the tractor frame. When fleets schedule Semi Trailer Kingpin Plate Replacement, they often discover uneven wear on the locking jaws or a plateaued oscillation on the fifth wheel. Replacing both isn’t mandatory—but it can be pragmatic, especially for severe-duty routes.

Industry snapshot

Trends I’m hearing: higher GCWs, tighter maintenance windows, and more fleets moving to four-way swinging fifth wheels to calm torsional stress. In fact, several intermodal operators told me the smoother coupling lowers driver frustration—small detail, big effect.

Product in focus: Fifth wheel J-3800

Origin: Shijiazhuang City, Hebei Province, China. Designed for ultra-large tonnage, with four-way swinging to track uneven sites (logging roads, mine spurs, port ramps). It seems that this model has found a niche where uptime is everything.

| Spec | Fifth wheel J-3800 (≈ values; real-world use may vary) |

|---|---|

| Rated load | Ultra-large tonnage class (SAE J2638 guidance) |

| Material | High-strength steel (e.g., Q345B/42CrMo for key components) |

| Swing | Four-way oscillation for complex road conditions |

| Kingpin compatibility | 2" and 3.5" kingpins (per ECE R55/SAE fitment) |

| Surface treatment | Shot-blast + anti-corrosion coating |

| Certs | ISO 9001; designed to meet SAE J2638/ECE R55 testing |

Process, testing, and service life

Typical flow: steel sourcing → CNC profiling → heat treatment (target hardness tuned to jaw wear resistance) → NDT (UT/MT on welds) → machining critical bores → shot blasting → coating → assembly → torque verification. Test protocols usually reference SAE J2638 (static/fatigue), with drawbar and jaw wear checks, plus corrosion cycles. In mixed duty, fleets report 8–12 years service life with proper greasing.

Use cases: mining haul roads, forestry, reefer lines, tanker fleets. During Semi Trailer Kingpin Plate Replacement, verify kingpin diameter wear, bolster plate flatness, and deck height—small misalignments can accelerate jaw wear.

Vendor comparison (field-perspective)

| Vendor | Load class | Certs | Lead time | Customization | Warranty |

|---|---|---|---|---|---|

| Land Fifth Wheel J-3800 | Ultra-large | ISO 9001; tests to SAE/ECE | Around 2–5 weeks | Jaw kits, plates, bolt patterns | 12–24 months (typ.) |

| Generic import | Medium–heavy | Varies | 4–8 weeks | Limited | 6–12 months |

| Remanufactured | Depends on core | Shop-level | Fast if in stock | Minimal | 3–6 months |

Customization and real-world feedback

Options include alternate bolt patterns, integrated lube channels, and jaw metallurgy tweaks for abrasive routes. Many customers say the four-way swing reduces frame twist on yard humps; drivers report cleaner coupling with less “clunk.” During Semi Trailer Kingpin Plate Replacement, spec a compatible skid plate thickness and confirm 2" vs 3.5" pin before delivery—obvious, yet surprisingly common misses.

Case note

A coastal container fleet swapped upper couplers on 40 trailers and paired them with J-3800 units. After 6 months, they logged fewer jaw replacements (anecdotal, but compelling) and reported steadier coupling angles on warped dock aprons.

Installation tips (quick)

- Measure deck height after Semi Trailer Kingpin Plate Replacement to keep driveline angles sane. - Verify lock indicator actuation and secondary safety latch. - Torque and re-torque mounting bolts after first 1,000 km. - Grease per schedule; inspect for brinnelling and jaw play quarterly.

References:

1. SAE J2638: Fifth Wheel Coupling With Kingpin Performance Requirements

2. UNECE Regulation No. 55: Mechanical coupling components of combinations of vehicles

3. ISO 9001: Quality Management Systems – Requirements

-

Fontaine No Slack II Adjustment: Enhancing Trailer Suspension Reliability & Safety

NewsNov.25,2025

-

Fontaine PDF Explained: Industrial Documentation, Specs & Innovation

NewsNov.24,2025

-

Heavy Haul Fifth Wheel – Essential Couplers for Oversized Transport

NewsNov.24,2025

-

Comprehensive Guide to Parts of the Fifth Wheel | Essential Components & Innovations

NewsNov.23,2025

-

Comprehensive Guide to 5th Wheel Parts: Key Components, Vendors & Future Trends

NewsNov.23,2025

-

Comprehensive Guide to Fifth Wheel Grease: Lubrication for Safety and Efficiency

NewsNov.22,2025