Oct . 25, 2025 00:25 Back to list

Air Suspension Series: Adjustable, Durable, Load-Leveling

Air Suspension Series is a key solution in the automotive industry, specifically within Manufacturing of automotive parts and accessories and Manufacturing of automotive suspension systems. This article explores how Shijiazhuang Land Auto Component Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Air Suspension Series Overview

- Benefits & Use Cases of Air Suspension Series in Manufacturing of automotive suspension systems

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in automotive industry

- Conclusion on Air Suspension Series from Shijiazhuang Land Auto Component Ltd.

Air Suspension Series Overview

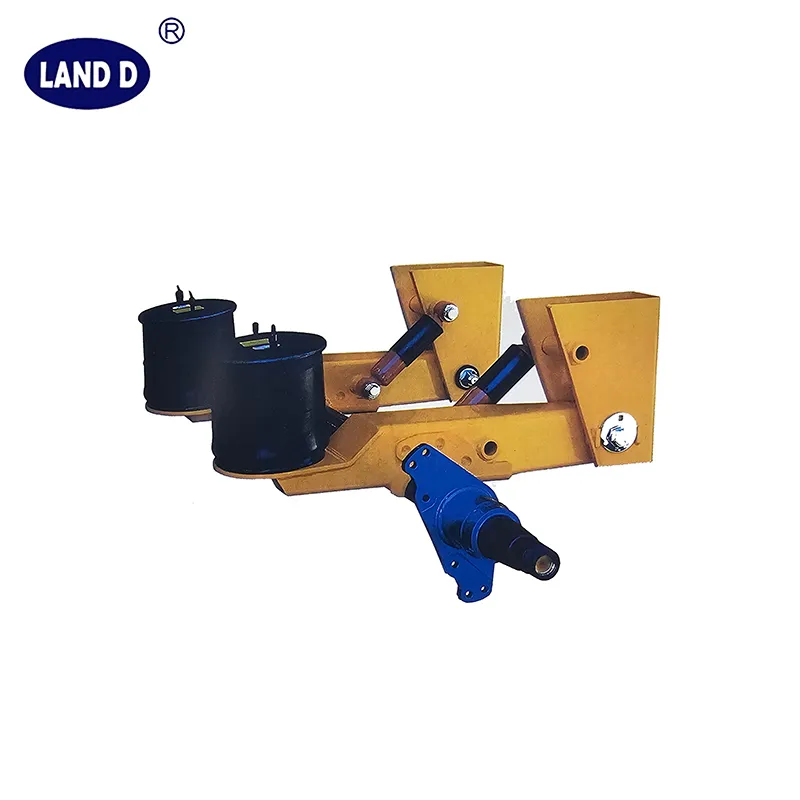

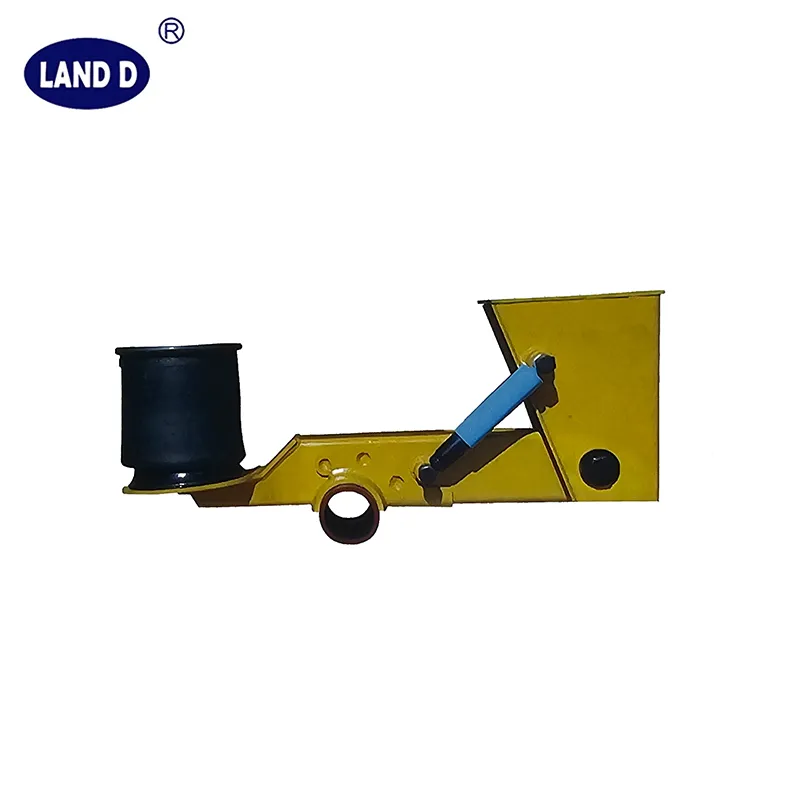

For commercial vehicle OEMs and Tier suppliers, the Air Suspension Series is a complete suspension solution engineered to enhance ride quality, load stability, and component longevity. It typically integrates air bellows, shock absorbers, torque arms, hangers, brackets, and height-control mechanisms into a modular package for single, tandem, or tridem axle configurations. In the automotive industry—especially the Manufacturing of automotive parts and accessories and the Manufacturing of automotive suspension systems—this integration streamlines assembly, supports standardized platforms, and helps reduce NVH across diverse trailer and truck applications. Shijiazhuang Land Auto Component Ltd. designs the series with manufacturing practicality in mind: consistent mounting geometries, robust weldments, corrosion-resistant finishes, and service-friendly bushings help reduce line complexity and lifetime maintenance. The company’s engineering discipline prioritizes fatigue resistance and dimensional accuracy, enabling predictable performance under high-mileage duty cycles and challenging road conditions. For B2B decision makers, this translates into a dependable, scalable suspension architecture that can be aligned with current platforms and adapted for future variants without costly redesigns. Explore specifications and options on the product page to match your build strategy and performance targets.

Benefits & Use Cases of Air Suspension Series in Manufacturing of automotive suspension systems

In high-throughput manufacturing environments, the Air Suspension Series fits seamlessly into OEM assembly lines for semi-trailers, logistics fleets, specialized carriers, and buses. Manufacturers benefit from consistent jigs and fixture points, modular subassemblies, and simplified logistics for replenishment parts. The series supports key use cases—line-haul, regional distribution, refrigerated transport, tankers, and container chassis—where ride stability, height control, and cargo protection directly influence warranty costs and customer satisfaction. Competitive advantages include weight-optimized structures for better payload efficiency, height-adjustable ride for dock alignment, and robust shock and bushing designs that help extend service intervals. For harsh operating conditions, durable surface treatments and reinforced brackets bolster resistance to corrosion and fatigue. Shijiazhuang Land Auto Component Ltd.’s sector expertise is reflected in its OEM collaboration mindset: precise mounting interfaces, documentation that speeds PPAP/APQP workflows, and engineering support that shortens integration time. Whether you are localizing a platform or launching a next-generation trailer family, the Air Suspension Series provides a scalable foundation that aligns product performance with production efficiency.

Cost, Maintenance & User Experience

Total cost of ownership is driven by uptime, tire longevity, and parts commonality. The Air Suspension Series emphasizes durable materials, readily accessible wear items, and standardized service kits to reduce workshop time. Pre-assembled modules can shorten installation, while replaceable bushings and easily sourced air springs aid field service. Height-control stability helps protect cargo and minimize tire scrub, which may translate into fewer claims and lower consumable expenses over the lifecycle. From a user standpoint, operators value predictable ride and handling, consistent dock height control, and reduced vibration that benefits sensitive loads. Feedback from partners in the Manufacturing of automotive parts and accessories segment highlights streamlined maintenance planning and improved component accessibility. For finance and procurement teams, these design choices support clearer budgeting, better spare-parts strategy, and a compelling ROI when benchmarked against frequent repairs or premature component wear. The result is a balanced TCO profile that serves both engineering and commercial objectives without compromising performance.

Sustainability & Market Trends in automotive industry

Sustainability is reshaping commercial vehicle design, with pressure to reduce emissions, optimize materials, and extend component life. Air suspension technology contributes by enabling ride-height control that can help reduce aerodynamic drag on highways, protecting loads to cut waste, and supporting even tire wear for fewer replacements. In parallel, the market is moving toward data-informed maintenance—pressure and height sensors that feed telematics and predictive dashboards—to further reduce downtime and material use. Shijiazhuang Land Auto Component Ltd. approaches the Air Suspension Series with lifecycle thinking: durability that supports longer service intervals, modularity that simplifies rebuilds, and attention to finishes that enhance corrosion resistance. The company’s forward-looking stance aligns with OEMs’ ESG priorities and the industry’s broader shift toward circular practices. As regulations evolve and fleets set tougher sustainability targets, selecting suspension systems that balance performance with maintainability will be essential to meeting both compliance and customer expectations.

Conclusion on Air Suspension Series from Shijiazhuang Land Auto Component Ltd.

For B2B decision makers in the automotive industry—spanning Manufacturing of automotive parts and accessories and Manufacturing of automotive suspension systems—the Air Suspension Series offers a robust, scalable platform that supports ride quality, reliability, and cost control. Backed by Shijiazhuang Land Auto Component Ltd.’s engineering rigor and OEM-focused service, it helps manufacturers streamline integration and deliver consistent, high-performing vehicles. Ready to evaluate fit and specifications? Contact us: email: info@land-d.cn. Visit our website: https://www.landfifthwheel.com or go directly to the product page at https://www.landfifthwheel.com/air-suspension-series.html.

-

Fontaine No Slack II Adjustment: Enhancing Trailer Suspension Reliability & Safety

NewsNov.25,2025

-

Fontaine PDF Explained: Industrial Documentation, Specs & Innovation

NewsNov.24,2025

-

Heavy Haul Fifth Wheel – Essential Couplers for Oversized Transport

NewsNov.24,2025

-

Comprehensive Guide to Parts of the Fifth Wheel | Essential Components & Innovations

NewsNov.23,2025

-

Comprehensive Guide to 5th Wheel Parts: Key Components, Vendors & Future Trends

NewsNov.23,2025

-

Comprehensive Guide to Fifth Wheel Grease: Lubrication for Safety and Efficiency

NewsNov.22,2025