Oct . 24, 2025 10:25 Back to list

Light Weight Fifth Wheel Trailers for Half-Ton Trucks

Light Duty Cast Steel Fifth Wheel-LD-37Q: a lighter hitch with serious backbone

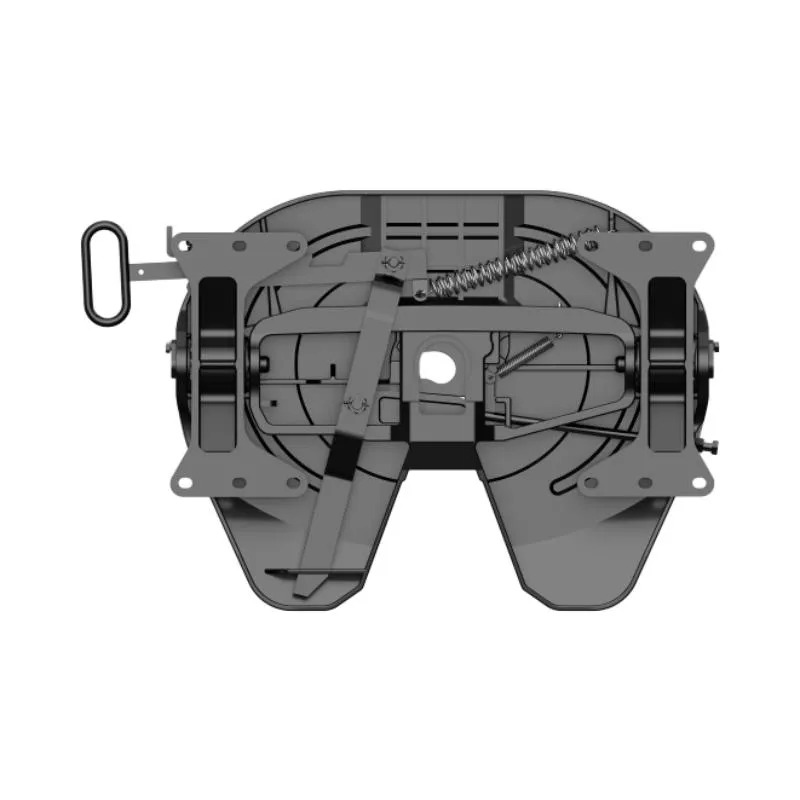

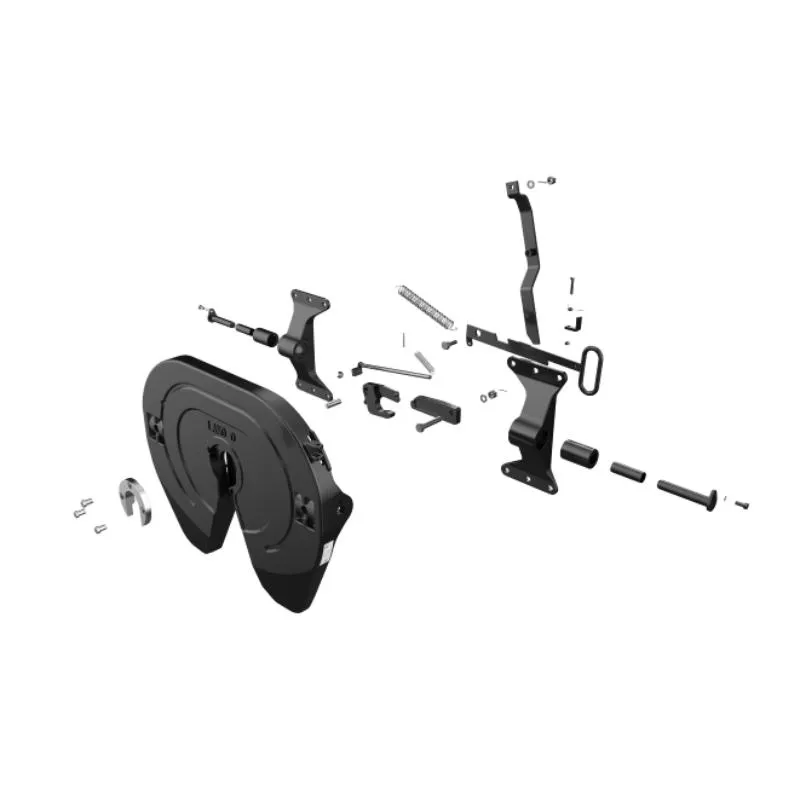

Fleet managers keep asking for Light Weight Fifth Wheel Trailers solutions that don’t compromise safety. Frankly, the market heard them. The LD-37Q from Shijiazhuang, Hebei (China) is one of those rare pieces of hardware that trims dead weight yet feels overbuilt where it matters. And yes, the panel is a one-piece high-strength cast steel plate—no seams to talk about, just mass where the forces funnel in.

Why lighter is winning now

Industry trend? Trim weight, keep uptime. With electrified tractors creeping in and regional-haul payloads getting tighter, every kilogram saved is either range or revenue. In fact, many customers say switching to Light Weight Fifth Wheel Trailers hardware was the easiest way to unlock a few dozen extra kilos of payload without touching the trailer.

LD-37Q quick specs (real-world may vary)

| Model | Light Duty Cast Steel Fifth Wheel—LD-37Q |

| Origin | Shijiazhuang City, Hebei Province, China |

| Top Plate Material | One-piece high-strength cast steel (impact-resistant) |

| Kingpin Compatibility | 2" standard; 3.5" optional on request (check tractor spec) |

| Indicative Load Class | Light-duty regional/urban haul; rating ≈ mid-teen to high-20 t GCW segments, application-dependent |

| Finish | Anti-corrosion coating; grease channels for easier maintenance |

How it’s made (and tested)

Materials and methods: high-strength cast steel, then precision CNC machining on the lock throat and wear faces. Heat treatment stabilizes microstructure; typical hardness targets are ≈ 240–300 HB (application-driven). Non-destructive testing (UT/MT) screens for subsurface flaws. Lock assemblies are proof-checked and function-tested.

Testing standards: sample units are fatigue-tested to SAE J2638 protocols, coupling geometry verified against ISO 1726, and coupling safety built to UN ECE R55 concepts. Salt-spray (≈ 240 h) helps validate coating durability. Service life in fleets is commonly 8–10 years with proper lubrication; to be honest, abuse can shrink that.

Where it shines

- Urban and regional haul where tare weight matters.

- Municipal fleets and vocational rigs with frequent coupling cycles.

- Agriculture and light construction—mixed terrain, moderate payloads.

Advantages: lighter top plate, stout lock, straightforward grease points. Several operators told me the LD-37Q reduced maintenance “fiddle time,” which—surprisingly—shows up in quarterly uptime reports.

Vendor snapshot (indicative)

| Vendor | Approx. Top Plate Mass | Load Class | Certs/Standards | Price Band |

|---|---|---|---|---|

| Land—LD-37Q | ≈ low- to mid-40s kg | Light-duty | ISO 1726, ECE R55, SAE J2638 | $ |

| Domestic Competitor A | ≈ 50–55 kg | Light/Medium | ECE R55 (declared) | $$ |

| Global Brand B | ≈ 45–52 kg | Light-duty | ISO/SAE suite | $$$ |

Customization, lead times, and support

Options include bolt patterns, top-plate heights, 2" vs 3.5" kingpin jaws, and coatings (black oxide, zinc-rich primer). Fleet branding and pre-lube setups are available. Typical lead time is a few weeks; export documents and ECE R55 conformity files can be bundled on request.

Field notes

Case 1 (regional grocer): swapping to Light Weight Fifth Wheel Trailers hardware netted ≈ 25–30 kg savings per tractor and fewer lock adjustments over six months. Driver feedback: “positive latch feel.”

Case 2 (municipal fleet): after 1,000+ coupling cycles, the LD-37Q showed even wear patterns; scheduled greasing every two weeks kept it drama-free. I guess simple maintenance wins.

Bottom line

If you’re chasing payload or range without gambling on safety, this one-piece cast steel LD-37Q is a sensible, tough pick for Light Weight Fifth Wheel Trailers deployments. Not flashy—just the right metal in the right places.

Authoritative citations

- UN ECE Regulation No. 55 – Mechanical coupling components. https://unece.org/transport/vehicle-regulations

- SAE J2638 – Fifth Wheel and Gooseneck Attachment Performance Test Procedures. https://www.sae.org/

- ISO 1726 – Commercial road vehicles — Interchangeability between towing vehicles and semi-trailers. https://www.iso.org/

-

Fontaine No Slack II Adjustment: Enhancing Trailer Suspension Reliability & Safety

NewsNov.25,2025

-

Fontaine PDF Explained: Industrial Documentation, Specs & Innovation

NewsNov.24,2025

-

Heavy Haul Fifth Wheel – Essential Couplers for Oversized Transport

NewsNov.24,2025

-

Comprehensive Guide to Parts of the Fifth Wheel | Essential Components & Innovations

NewsNov.23,2025

-

Comprehensive Guide to 5th Wheel Parts: Key Components, Vendors & Future Trends

NewsNov.23,2025

-

Comprehensive Guide to Fifth Wheel Grease: Lubrication for Safety and Efficiency

NewsNov.22,2025