Oct . 16, 2025 10:10 Back to list

American Type Welding Series Suspension | Heavy-Duty OEM

American Type Welding Series Suspension is a key solution in the manufacturing industry, specifically within Special Equipment Manufacturing Industry and Manufacturing of welding and cutting equipment. This article explores how Shijiazhuang Land Auto Component Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- American Type Welding Series Suspension Overview

- Benefits & Use Cases of American Type Welding Series Suspension in Manufacturing of welding and cutting equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on American Type Welding Series Suspension from Shijiazhuang Land Auto Component Ltd.

American Type Welding Series Suspension Overview

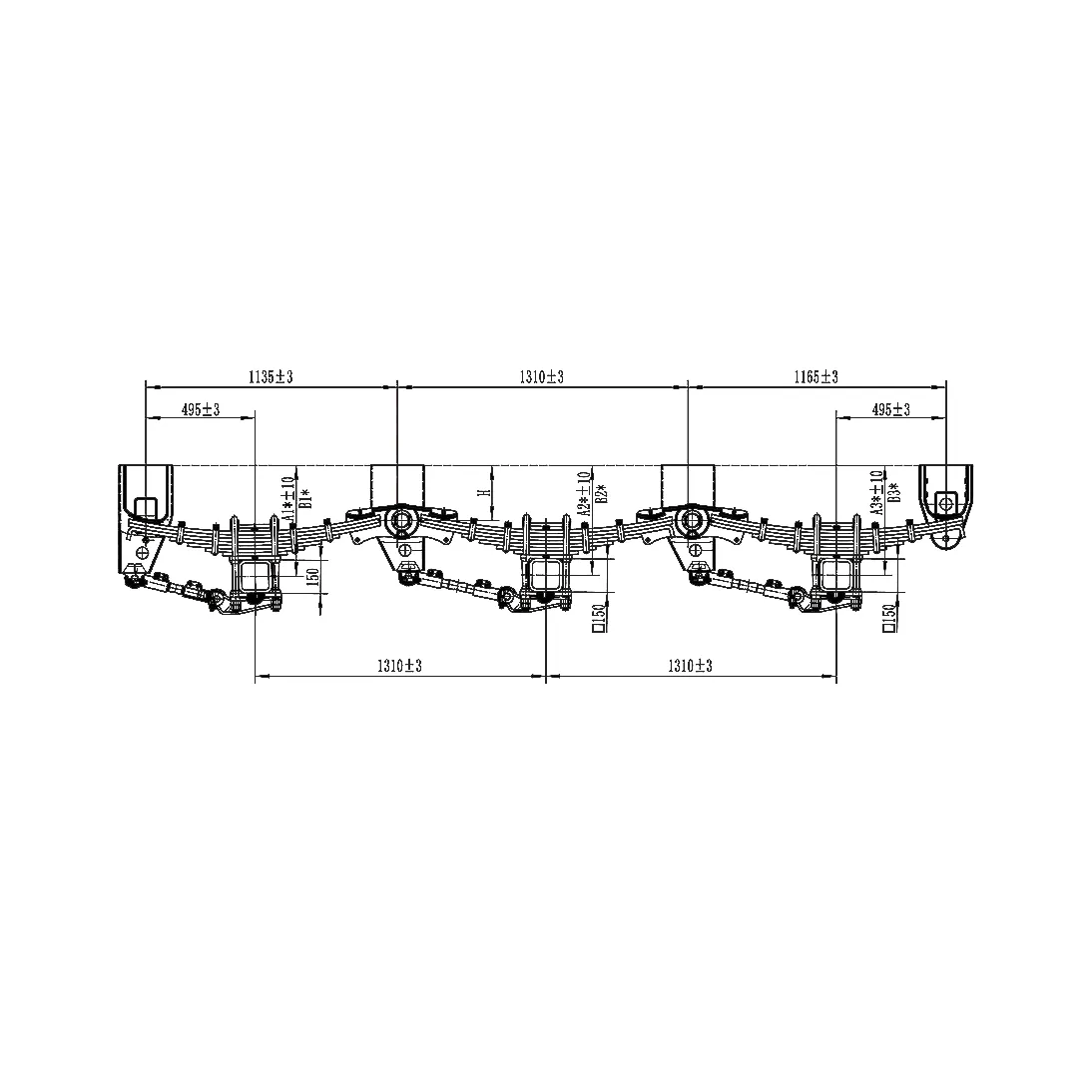

The American Type Welding Series Suspension is a welded trailer suspension assembly designed for heavy-duty hauling and precision alignment in demanding operations. Built around robust hangers, equalizers, torque arms, and leaf-spring interfaces, it provides a stable platform for trailers that carry high-value assets—including welding power sources, cutting tables, gas cylinders, and fabrication tooling. Its “American type” geometry ensures compatibility with commonly used axle seats, spring centers, and brake configurations favored by North American-style trailers, making integration straightforward for OEMs and fleet retrofit programs.

Shijiazhuang Land Auto Component Ltd. engineers these suspensions with high-strength steel components, precision jigs, and consistent welding processes for structural integrity. Attention to axle spacing and track-width tolerances helps maintain straight-line stability and even tire loading. Options can include different hanger heights, spring capacities, and multi-axle setups, giving B2B decision makers flexibility to tailor ride characteristics and payload requirements. Backed by repeatable quality control and reliable supply, Shijiazhuang Land Auto Component Ltd. has become a trusted manufacturer for customers across the Special Equipment Manufacturing Industry seeking durable suspensions that perform in real-world conditions.

Benefits & Use Cases of American Type Welding Series Suspension in Manufacturing of welding and cutting equipment

In the Manufacturing of welding and cutting equipment, precision transport matters. The American Type Welding Series Suspension helps protect sensitive power sources, plasma and oxy-fuel equipment, torch systems, and calibration tooling during transit by reducing shock and vibration. For mobile welding service trailers, generator carriers, and cylinder distribution fleets, a stable suspension is critical to safety, uptime, and the condition of delivered equipment.

Key advantages include rugged welded construction for high load cycles, consistent axle alignment to support predictable tire wear, and adaptable configurations for single, tandem, or tri-axle applications. The suspension’s straightforward architecture simplifies installation and field service, with common wear items—such as bushings and U-bolts—readily accessible for maintenance teams. For OEMs building specialized trailers for fabrication shops or construction sites, Shijiazhuang Land Auto Component Ltd. delivers practical engineering support, reliable lead times, and product configurations that match payload, road conditions, and fleet standards. The result is a suspension solution that supports both operational efficiency and long-term equipment protection.

Cost, Maintenance & User Experience

Total cost of ownership for the American Type Welding Series Suspension is driven by durability, maintenance intervals, and uptime. Welded, high-strength components contribute to a long service life, while standardized parts simplify stocking and repairs. For fleets moving welding and cutting equipment, predictable handling reduces incidental damage to cargo and lowers the indirect costs of rework and delays. Over time, consistent axle geometry can support better tire life and fuel efficiency, further improving ROI.

Maintenance is straightforward: routine torque checks, periodic bushing inspections, alignment verification after impacts, and corrosion monitoring in harsh environments. Many customers in the Special Equipment Manufacturing Industry value how the suspension’s accessible layout shortens service windows and minimizes downtime. Feedback commonly highlights stable towing characteristics, ease of installation on new builds or retrofits, and reliable performance under mixed road conditions. These practical benefits translate into measurable operational continuity for fabrication plants, field-service teams, and distributors who depend on dependable transport to meet customer commitments.

Sustainability & Market Trends in manufacturing

Sustainability in modern manufacturing emphasizes longer product lifecycles, efficient material use, and reduced environmental impact. The American Type Welding Series Suspension supports these goals with robust construction that extends service life and minimizes replacements. Durable coatings and optimized designs help resist corrosion and wear, lowering scrap rates and waste over the product’s lifetime. For B2B decision makers pursuing ESG objectives, fewer unplanned repairs and less frequent component turnover can positively influence both cost and environmental metrics.

Market trends also favor safety, traceability, and efficiency. As regulations tighten and uptime expectations rise, manufacturers seek suspensions that deliver predictable performance across diverse loads and terrains. Shijiazhuang Land Auto Component Ltd. invests in consistent production methods and quality controls that align with these trends, while exploring process improvements—such as better surface protection and precision fixtures—to reduce rework and improve throughput. This forward-thinking approach positions the company as an eco-conscious, reliable partner for OEMs and fleets in the welding and cutting equipment sector.

Conclusion on American Type Welding Series Suspension from Shijiazhuang Land Auto Component Ltd.

For organizations operating within the Special Equipment Manufacturing Industry and the Manufacturing of welding and cutting equipment, the American Type Welding Series Suspension delivers reliable handling, durability, and straightforward maintenance. Its compatibility with prevalent axle and brake layouts streamlines integration, while robust construction supports long-term value. Shijiazhuang Land Auto Component Ltd. stands out for practical engineering support, dependable quality, and a clear focus on customer operations.

Contact us: email: info@land-d.cn

Visit our website: https://www.landfifthwheel.com

-

Fontaine No Slack II Adjustment: Enhancing Trailer Suspension Reliability & Safety

NewsNov.25,2025

-

Fontaine PDF Explained: Industrial Documentation, Specs & Innovation

NewsNov.24,2025

-

Heavy Haul Fifth Wheel – Essential Couplers for Oversized Transport

NewsNov.24,2025

-

Comprehensive Guide to Parts of the Fifth Wheel | Essential Components & Innovations

NewsNov.23,2025

-

Comprehensive Guide to 5th Wheel Parts: Key Components, Vendors & Future Trends

NewsNov.23,2025

-

Comprehensive Guide to Fifth Wheel Grease: Lubrication for Safety and Efficiency

NewsNov.22,2025