Oct . 14, 2025 08:10 Back to list

American Type Welding Series Suspension - Heavy-Duty OEM

American Type Welding Series Suspension — field notes from a road-tested product

I’ve been in and out of trailer plants for years, and, to be honest, welded suspensions are where the real craft shows. The unit coming out of Shijiazhuang City, Hebei, China caught my eye because fleets kept mentioning lower downtime. That’s unusual. The American Type Welding Series Suspension sits in that sweet spot between classic, proven design and the more measured push toward automation (robotic GMAW, better jigs, smarter coatings).

What’s trending in heavy trailer suspensions

Three currents, if you ask around: tougher steels (A572-class equivalents), cleaner welds (AWS D1.1 procedures), and coatings that actually survive winter brine. Fleets also want easy bushing swaps without burning half a shift. The American Type Welding Series Suspension leans into that: high-strength low-alloy steel, robotic welding on critical seams, and a belt-and-suspenders finish—shot blast, phosphate, then e-coat or powder. Customers say the bushings “don’t fight you” during service, which, frankly, matters more than a glossy brochure.

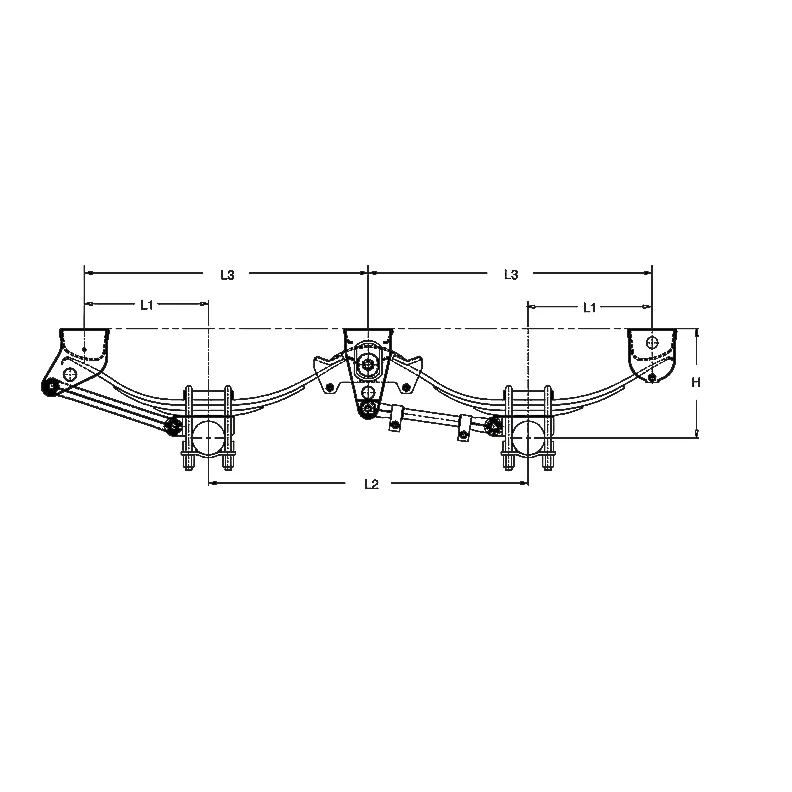

Typical specifications (field-verified ranges)

| Parameter | Typical Value | Notes |

|---|---|---|

| Axle spacing | ≈ 49–54 in | Customizable to fleet spec |

| Capacity (per axle) | 20K–25K lb | Real-world use may vary |

| Material | HSLA steel (≈ ASTM A572 Gr.50) | Mill certs available |

| Welding process | Robotic GMAW + manual finishing | Per AWS D1.1 WPS/PQR |

| Coating | Shot blast + phosphate + e-coat/powder | Salt spray ≈ 720 h (ASTM B117) |

| Service life | 5–8 years typical | Duty cycle and roads matter a lot |

Process flow and testing

Materials arrive with heat numbers; frames are jigged for dimensional control; robotic welds cover high-stress nodes; critical fillets get UT or MT spot checks per AWS D1.1. After stress-relief where needed, parts are shot blasted, phosphated, and coated. QC runs torque audits on hanger bolts, bushing press-fit checks, and a fatigue rig test (≈ 2.0×106 cycles at design load). Brake interface points align with FMVSS 121 assumptions for air-brake hardware integration. It sounds dry, but it’s what keeps fleets out of the ditch.

Where it’s used

Dry vans, reefers, flatbeds, and, increasingly, regional tankers. One Texas fleet told me they swapped to the American Type Welding Series Suspension on a batch of flats; their comment was simple: “We stopped chasing cracked brackets.” Another customer running coastal salt routes said the coating held up “surprisingly well” past two winters.

Advantages that actually show up on the ledger

- Stout hanger/torque arm geometry reduces scrub and bushing abuse.

- Real alignment stability; fewer tire wear complaints.

- Service-friendly bushings and accessible torque points.

- Consistent weld quality from robotic passes on critical joints.

Vendor landscape (quick take)

| Vendor | Certifications | Lead Time | Customization | Warranty |

|---|---|---|---|---|

| Land (Hebei, China) | ISO 9001, IATF 16949 (site dependent) | ≈ 4–8 weeks | Axle spacing, hanger height, coating | 12–24 months typical |

| Brand A (US) | ISO 9001, AWS D1.1 audited | ≈ 6–10 weeks | Moderate options | 12 months |

| Brand B (EU) | ISO 9001, ISO 3834 | ≈ 8–12 weeks | High (engineer-to-order) | 24 months |

Customization and integration

Options include axle seat size, hanger drop, track width, shock mounts, ride-height shims, and coating spec. For fleets mixing new builds and retrofits, the American Type Welding Series Suspension can be delivered with bracket hole patterns to match legacy frames—saves torch time.

Quick case snapshots

- Flatbed fleet, Southwest US: 2× tire life improvement on spread-axle sets after geometry tweak and bushing spec change.

- Reefer fleet, Great Lakes: corrosion complaints dropped after switch to e-coat + powder; hardware still needs love, as always.

Bottom line? If you want an HSLA, AWS-aligned welded suspension with sensible serviceability and real anti-corrosion work, this one deserves a look. Origin: Shijiazhuang City, Hebei Province, China—where, apparently, they’re getting the details right.

Authoritative references

- AWS D1.1/D1.1M Structural Welding Code—Steel: https://www.aws.org

- IATF 16949 Automotive Quality Management: https://www.iatfglobaloversight.org

- ASTM A572/A572M High-Strength Low-Alloy Steel: https://www.astm.org

- FMVSS No. 121 Air Brake Systems (integration context): https://www.nhtsa.gov

- ISO 3834 Welding Quality Requirements: https://www.iso.org

-

Fontaine PDF Explained: Industrial Documentation, Specs & Innovation

NewsNov.24,2025

-

Heavy Haul Fifth Wheel – Essential Couplers for Oversized Transport

NewsNov.24,2025

-

Comprehensive Guide to Parts of the Fifth Wheel | Essential Components & Innovations

NewsNov.23,2025

-

Comprehensive Guide to 5th Wheel Parts: Key Components, Vendors & Future Trends

NewsNov.23,2025

-

Comprehensive Guide to Fifth Wheel Grease: Lubrication for Safety and Efficiency

NewsNov.22,2025

-

Comprehensive Guide to 5th Wheel Height – Optimize Trucking Safety & Efficiency

NewsNov.22,2025