Oct . 26, 2025 10:15 Back to list

American Type Welding Series Suspension – Heavy-Duty OEM

Field Notes on the American Type Welding Series Suspension

Made in Shijiazhuang City, Hebei Province, China — and yes, that matters because the local steel ecosystem and welding expertise have quietly levelled up in the last decade. To be honest, I went in skeptical; I left impressed by the consistency I saw on the weld beads and the hangers’ parallelism.

Where the market is headed

Operators want fewer grease points, longer bushing life, and fast install kits. In fact, export buyers increasingly ask for powder-coat finishes and robotic-MAG welding certification proof. Many customers say they want “fit-and-forget” suspension modules that tolerate rough roads and mixed fleets.

Key Specs (typical, may vary by configuration)

| Capacity per axle | ≈ 9–13 t (real-world use may vary) |

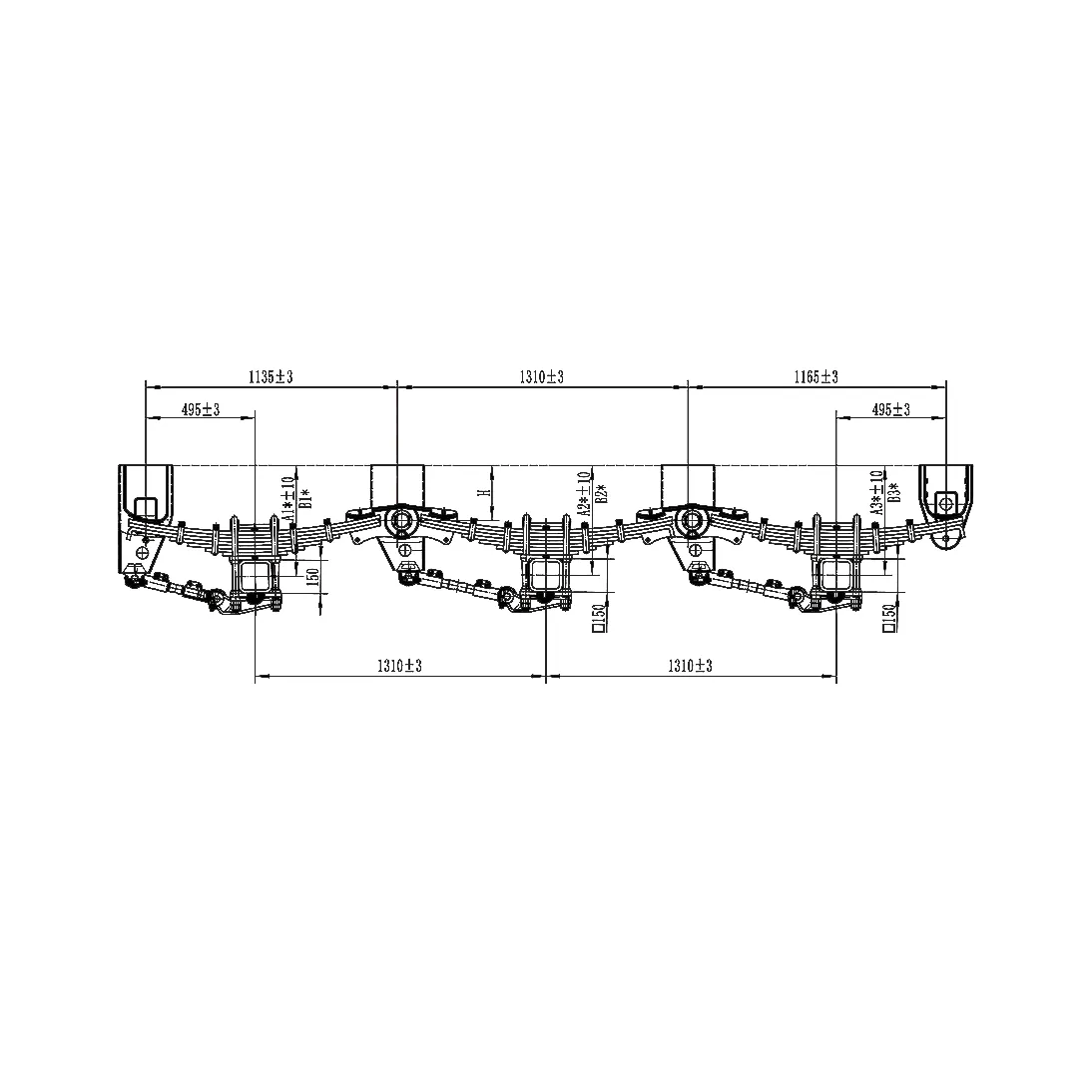

| Axle spacing | 1,310–1,350 mm options |

| Ride height | ≈ 180–240 mm (design dependent) |

| Hanger/Bracket steel | Q345/SM490-grade, shot-blasted |

| Weld method | CO₂/MAG with robotic passes + manual cap |

| Bushings | Wear-resistant rubber or PU; greaseable pins optional |

| Surface finish | Zinc-rich primer + powder coat (ASTM B117 tested) |

| Bolt grade | 8.8/10.9; torque spec sheet supplied |

| Service life | ≈ 5–8 years under normal load cycles |

Process flow and testing

- Materials: Q345 structural steel; certified mill reports kept on file.

- Methods: robotic MAG root, manual capping, stress-relief, shot blasting SA 2.5, powder coating.

- Testing: welds qualified to AWS D1.1; coating verified via ASTM B117 (≥ 480 h); environmental per SAE J1455; dimensional checks with jigs and CMM spot audits.

- Certifications: typically ISO 9001; some lots audited against IATF 16949 practices (ask for current certs).

In bench tests, a representative American Type Welding Series Suspension module completed >1.0×10⁶ fatigue cycles at nominal load, with bushing wear measured at ≈ 0.3–0.6 mm—respectable for mixed-road fleets.

Applications and advantages

- Semi-trailers: flatbed, drop-deck, container chassis, tankers, dump.

- Mining/logistics corridors where impact loads and dust are routine.

- Advantages: easy hanger alignment, robust brackets, replaceable wear parts, and predictable ride height.

Customer feedback: “Installed two tridem sets last winter; surprisingly low bushing wear after harvest season,” said a Midwest fleet manager. Another buyer in the Gulf region praised rust resistance after monsoon runs.

Vendor landscape (quick comparison)

| Vendor | Origin | Welding standard | Lead time | Customization | Notes |

|---|---|---|---|---|---|

| Manufacturer A (Land Fifth Wheel) | Shijiazhuang, China | AWS D1.1 procedures | ≈ 20–35 days | High (axle spacing, coating, bushings) | Good price-to-durability |

| Vendor B (Importer) | Mixed | Varies; request WPS/WPQR | ≈ 30–60 days | Medium | Broader portfolio, higher cost |

| Vendor C (Aftermarket) | Regional | Shop-level qual. | Quick for small lots | Low | Convenient, variable QC |

Customization and integration tips

- Specify axle track, hanger pitch, and brake chamber orientation up front.

- Consider high-salt spec (≥ 720 h ASTM B117) if coastal or winter service dominates.

- Ask for torque charts and install jigs; it speeds line fitment by ≈ 15–20%.

American Type Welding Series Suspension has become a sensible pick when you want durable hangers, clean welds, and a fair lead time—nothing flashy, just field-proven hardware that shows up and does the job.

Authoritative citations

- AWS D1.1/D1.1M: Structural Welding Code—Steel (American Welding Society)

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus (ASTM International)

- SAE J1455: Recommended Environmental Practices for Electronic/Electrical Equipment in Heavy-Duty Vehicles (SAE International)

- ISO 9001: Quality Management Systems—Requirements (International Organization for Standardization)

-

Fontaine No Slack II Adjustment: Enhancing Trailer Suspension Reliability & Safety

NewsNov.25,2025

-

Fontaine PDF Explained: Industrial Documentation, Specs & Innovation

NewsNov.24,2025

-

Heavy Haul Fifth Wheel – Essential Couplers for Oversized Transport

NewsNov.24,2025

-

Comprehensive Guide to Parts of the Fifth Wheel | Essential Components & Innovations

NewsNov.23,2025

-

Comprehensive Guide to 5th Wheel Parts: Key Components, Vendors & Future Trends

NewsNov.23,2025

-

Comprehensive Guide to Fifth Wheel Grease: Lubrication for Safety and Efficiency

NewsNov.22,2025