Oct . 26, 2025 00:20 Back to list

Germany Type Suspension Clamp - Galvanized, High Load, OEM

Germany Type Suspension is a key solution in the manufacturing industry, specifically within automobile manufacturing industry and Manufacturing of automotive parts and accessories. This article explores how Shijiazhuang Land Auto Component Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Germany Type Suspension Overview

- Benefits & Use Cases of Germany Type Suspension in Manufacturing of automotive parts and accessories

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Germany Type Suspension from Shijiazhuang Land Auto Component Ltd.

Germany Type Suspension Overview

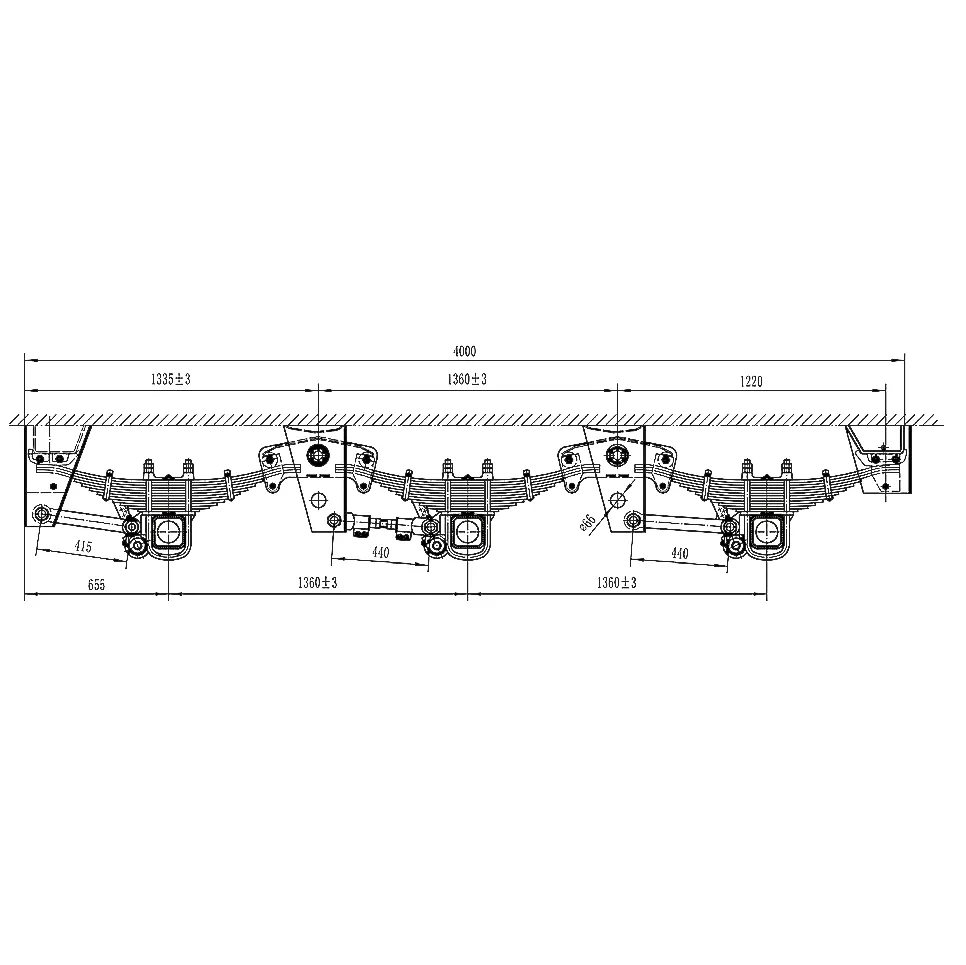

Germany Type Suspension typically refers to a robust mechanical suspension system designed around widely adopted German-standard axle interfaces and geometry. For B2B decision makers in the automobile manufacturing industry—especially trailer OEMs and component assemblers—it delivers dependable load-carrying capacity, stability, and long service life in demanding applications. A complete assembly usually includes hangers, equalizers, leaf springs, torque rods, U-bolts, and bolt-on axle seats engineered to keep alignment stable under heavy loads and rough road conditions. Technically, these suspensions are engineered with high-strength, low-alloy steels, precision-welded brackets, and bushings that minimize friction and wear. Typical options include multiple ride heights, axle spacing and track widths, and axle load ratings that suit a range of applications from standard freight to construction and tanker fleets. Coating options such as shot blasting and e-coat or powder finish help resist corrosion and extend lifecycle value. Shijiazhuang Land Auto Component Ltd. manufactures Germany Type Suspension with strict process control, consistent metallurgy, and repeatable dimensions that simplify OEM line assembly. Leveraging modern fabrication and inspection practices, the company provides configurable, high-quality units that meet the realities of high-mileage, high-uptime operations.

- Built for semi-trailers, special vehicles, and heavy-duty logistics where durability and stability are critical.

- Options for ride height, axle spacing, and bushing types to suit regional road conditions and payload targets.

- Produced by Shijiazhuang Land Auto Component Ltd., an experienced manufacturer focused on consistency and integration ease.

Benefits & Use Cases of Germany Type Suspension in Manufacturing of automotive parts and accessories

In the Manufacturing of automotive parts and accessories, Germany Type Suspension supports high-throughput trailer production lines and aftermarket programs. Common use cases include flatbeds, container chassis, tippers, tankers, low-bed trailers, and regional distribution fleets. Its mechanical simplicity and ruggedness are advantageous for operations that prioritize predictable maintenance, strong axle alignment, and minimized tire wear. Key advantages include modular hangers and equalizers for straightforward installation, reinforced brackets to manage high torsional loads, and bushing options—such as rubber-metal or maintenance-friendly designs—to match fleet service philosophies. The suspension’s geometry provides consistent ride stability, helping protect sensitive cargo and reducing stress on the chassis. For OEMs, standardized interfaces and clear tolerances shorten build cycles and help maintain uniform quality across models. Shijiazhuang Land Auto Component Ltd. adds value with application engineering support, drawings for rapid integration, and flexible configurations aligned to customer BOMs. From pilot runs to scaled production, the company’s Germany Type Suspension solutions are designed to fit seamlessly into the workflows of component manufacturers and trailer assemblers, improving productivity while maintaining strict quality standards.

- Ideal for heavy-haul, construction logistics, and general freight trailers requiring stable, durable suspension.

- Modular, interchangeable parts help simplify inventory and speed assembly/servicing.

- Backed by Shijiazhuang Land Auto Component Ltd.’s application support and dependable delivery schedules.

Cost, Maintenance & User Experience

Total cost of ownership for a Germany Type Suspension is shaped by durability, tire wear impact, servicing intervals, and parts availability. The mechanical layout minimizes complexity, while robust bushings, correctly specified leaf packs, and corrosion-resistant finishes help extend service life. For OEMs, consistent tolerances reduce rework and speed installation—lowering line costs. For fleets, reliable alignment performance and durable wear components contribute to predictable maintenance and improved ROI over the lifecycle. Customer feedback in the automobile manufacturing industry often highlights fewer alignment-related adjustments when suspensions are installed with proper jigs and torque sequences. Many users also note streamlined inspections thanks to easy visual access to key wear points (bushings, U-bolts, equalizers). Depending on spec, bushings may be maintenance-free or require periodic greasing—either way, the maintenance plan can be aligned with existing PM schedules to minimize downtime. Shijiazhuang Land Auto Component Ltd. supports users with clear installation guidance, recommended torque values, and parts traceability to simplify aftersales management. With commonly used fasteners and standardized components, spare parts stocking is straightforward—helping OEMs and distributors reduce inventory risk while ensuring quick turnaround on service jobs.

- Balanced TCO via long-life components, accessible service points, and stable alignment.

- Positive user experience: predictable maintenance windows and easy inspection of critical wear items.

Sustainability & Market Trends in manufacturing

Manufacturing trends are moving toward lighter, stronger components; longer service intervals; and design-for-repair to support circularity. For suspensions, that translates into optimized steel grades, efficient coatings, and modular parts that can be replaced without scrapping entire assemblies. As regulations emphasize road safety and environmental stewardship, OEMs increasingly specify durable, corrosion-resistant finishes and standardized components that lower waste throughout the product lifecycle. The Germany Type Suspension aligns well with these themes: rugged, serviceable designs improve longevity and reduce material consumption over time. When paired with high-quality surface treatments and precise machining, the result is fewer early-life failures and more predictable overhaul cycles—benefits that matter as fleets pursue lower emissions per ton-kilometer by keeping equipment in peak condition. Shijiazhuang Land Auto Component Ltd. positions itself as forward-thinking and eco-conscious by focusing on efficient fabrication processes, surface treatments that help extend product life, and packaging practices that reduce waste during shipping. The company’s emphasis on consistency and reparability supports customers’ sustainability objectives while maintaining the performance benchmarks required by modern logistics networks.

- Durable, repairable designs help reduce lifecycle waste and support circular maintenance strategies.

- Shijiazhuang Land Auto Component Ltd. focuses on longevity-oriented materials and finishes to align with evolving sustainability targets.

Conclusion on Germany Type Suspension from Shijiazhuang Land Auto Component Ltd.

For B2B leaders in the automobile manufacturing industry, Germany Type Suspension provides a dependable, serviceable foundation for trailer and special-vehicle platforms. Its robust architecture, standardized interfaces, and flexible configurations align with OEM build efficiency and fleet uptime goals. Shijiazhuang Land Auto Component Ltd. backs this with consistent quality, application support, and practical options that fit real-world workloads. Ready to evaluate configurations for your next project? Contact us: email: info@land-d.cn. Visit our website: https://www.landfifthwheel.com. Explore the product page here: Germany Type Suspension.

-

Fontaine No Slack II Adjustment: Enhancing Trailer Suspension Reliability & Safety

NewsNov.25,2025

-

Fontaine PDF Explained: Industrial Documentation, Specs & Innovation

NewsNov.24,2025

-

Heavy Haul Fifth Wheel – Essential Couplers for Oversized Transport

NewsNov.24,2025

-

Comprehensive Guide to Parts of the Fifth Wheel | Essential Components & Innovations

NewsNov.23,2025

-

Comprehensive Guide to 5th Wheel Parts: Key Components, Vendors & Future Trends

NewsNov.23,2025

-

Comprehensive Guide to Fifth Wheel Grease: Lubrication for Safety and Efficiency

NewsNov.22,2025