Aug . 31, 2025 00:20 Back to list

Best Light Weight Fifth Wheel Trailers - Easy Towing | Comfort

The Evolution and Impact of light weight fifth wheel trailers in Modern Logistics

In the demanding landscape of commercial logistics and heavy-duty transportation, efficiency, durability, and operational cost reduction are paramount. The advent and continuous refinement of light weight fifth wheel trailers represent a significant leap forward, offering compelling advantages over traditional, heavier alternatives. These specialized components, such as the Light Duty Cast Steel Fifth Wheel-LD-37Q, are engineered to optimize payload capacity, enhance fuel economy, and minimize wear on tractor units, directly impacting the profitability and sustainability of fleet operations.

This comprehensive guide delves into the technical intricacies, market dynamics, and operational benefits of these essential connection systems. We explore the industry trends driving their adoption, the rigorous manufacturing processes that ensure their reliability, and their indispensable role across a diverse range of B2B applications.

Key Industry Trends in Fifth Wheel Technology

The market for light weight fifth wheel trailers is influenced by several converging trends, primarily driven by regulatory pressures, economic considerations, and technological advancements:

- Fuel Efficiency Imperative: Rising fuel costs and stringent emissions regulations (e.g., Euro VI, EPA 2027) are pushing manufacturers and fleet operators towards solutions that reduce overall vehicle weight. Lightweight components directly contribute to lower fuel consumption and reduced carbon footprints.

- Increased Payload Capacity: For many freight segments, maximizing payload per trip is crucial. By reducing the tare weight of the tractor-trailer combination, light weight fifth wheel systems allow for greater cargo volume or weight within legal limits, optimizing logistics efficiency.

- Material Science Advancements: Innovations in high-strength steels, advanced cast alloys, and even composite materials are enabling the production of robust yet lighter fifth wheel designs without compromising structural integrity or safety.

- Smart Logistics & Connectivity: While less direct, the broader trend towards telematics and predictive maintenance is also impacting fifth wheel design, with some advanced units incorporating sensors for coupling status or load distribution.

- Enhanced Safety Features: Ongoing developments include improved locking mechanisms, visual and audible coupling indicators, and reduced maintenance requirements, all contributing to safer operations.

The demand for new fifth wheel for sale consistently reflects these trends, with buyers prioritizing reliability, low maintenance, and weight reduction.

Manufacturing Process of Light Duty Cast Steel Fifth Wheels

The production of a high-quality light weight fifth wheel involves a meticulous multi-stage process, ensuring precision, durability, and adherence to stringent industry standards. Our Light Duty Cast Steel Fifth Wheel-LD-37Q exemplifies this rigorous manufacturing approach:

Schematic Process Flow:

- Material Selection & Preparation:

- High-grade alloy steels (e.g., ASTM A148/A27, EN 10083) specifically chosen for their optimal strength-to-weight ratio and fatigue resistance. These materials provide the necessary robustness while contributing to the overall lightweight objective.

- Raw materials are inspected for chemical composition and mechanical properties to meet design specifications.

- Casting:

- Molten steel is poured into precision molds, often utilizing sand casting or investment casting techniques for complex geometries. This process allows for intricate designs that reduce material usage without sacrificing strength.

- Controlled cooling ensures optimal microstructure and minimizes internal stresses.

- Heat Treatment:

- Components undergo quenching and tempering processes to achieve desired hardness, toughness, and ductility. This is critical for the long service life of a fifth wheel under dynamic loads.

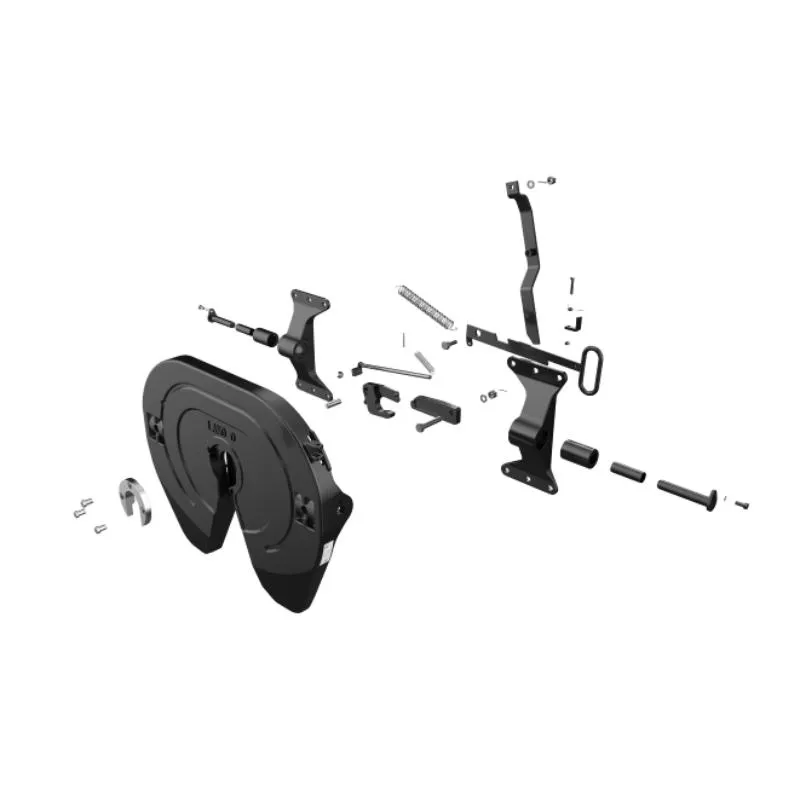

- CNC Machining:

- Precision machining of critical interfaces (e.g., kingpin jaw, mounting holes) to micron tolerances using Computer Numerical Control (CNC) equipment. This ensures perfect fitment and articulation, reducing wear and improving safety.

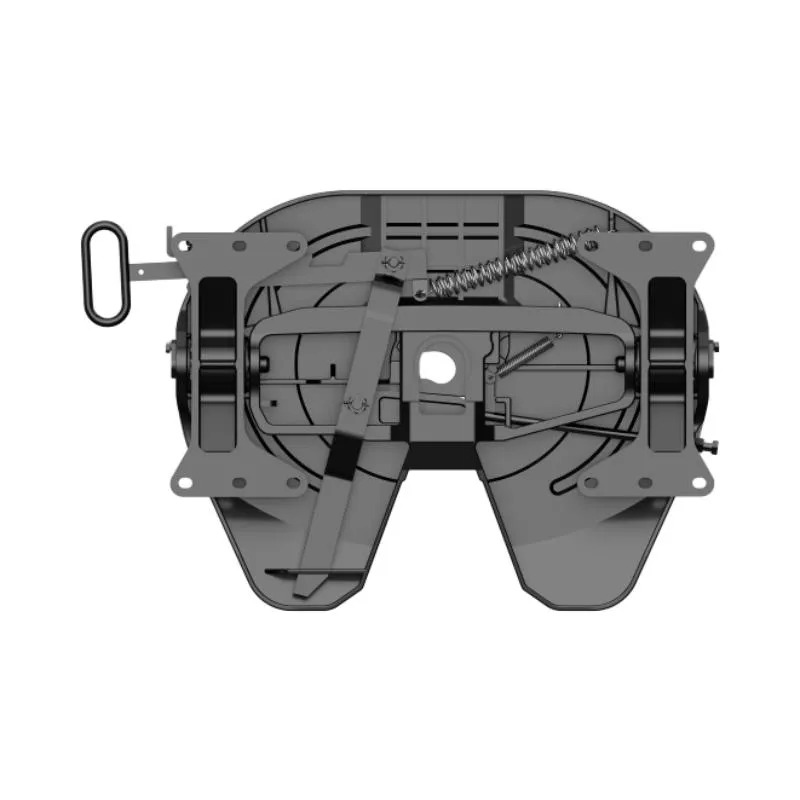

- Assembly:

- Integration of various components, including locking mechanisms, wear plates, and pivot pins.

- Surface Treatment & Coating:

- Application of protective coatings (e.g., epoxy paint, powder coating, galvanization) to provide superior corrosion resistance, extending the service life even in harsh operating environments. This is particularly beneficial in target industries like petrochemical or maritime logistics.

- Quality Control & Testing:

- Non-destructive testing (NDT) such as ultrasonic inspection and magnetic particle inspection for internal flaws.

- Mechanical tests: fatigue testing, load bearing capacity tests (e.g., according to ISO 8716, SAE J2227 standards), and impact resistance.

- Dimensional verification against engineering drawings.

- Each unit, including our LD-37Q, must pass rigorous checks to ensure compliance with international standards like ISO 9001, TÜV, and relevant ANSI standards, guaranteeing a typical service life exceeding 10 years under proper maintenance.

Technical Specifications and Parameters

Understanding the core technical parameters of light weight fifth wheel trailers is crucial for optimal selection and integration. The Light Duty Cast Steel Fifth Wheel-LD-37Q, a prime example, demonstrates a balance of strength and reduced mass, making it ideal for various applications.

Product Specification: Light Duty Cast Steel Fifth Wheel-LD-37Q

| Parameter | Specification (LD-37Q) | Description/Benefit |

|---|---|---|

| Type | Cast Steel, Light Duty | Optimized for weight and durability in medium-duty applications. |

| Material | High-Strength Alloy Steel | Superior mechanical properties, corrosion resistance. |

| D-Value (kN) | 150 kN | Dynamic load capacity, indicating robust connection. |

| Max Vertical Load (SV) | 18,000 kg (18 Tons) | Suitable for a wide range of trailer weights. |

| Approx. Unit Weight | 145 kg (320 lbs) | Significantly lighter than many heavy-duty counterparts, enhancing payload. |

| Kingpin Size | 2-inch (50.8 mm) standard | Universal compatibility with standard semi-trailers. |

| Mounting Height Range | Adjustable, typically 150-300mm | Flexibility for various chassis configurations. |

| Approval Standards | ISO 8716, ECE R55, TUV | Ensures international compliance and safety. |

Application Scenarios and Technical Advantages

The distinct advantages of light weight fifth wheel trailers make them indispensable across a variety of demanding industrial sectors:

Target Industries:

- Petrochemical Industry: Transportation of volatile and high-value liquid or gas cargo where every kilogram saved contributes to increased volume and reduced fuel expenditure. The corrosion resistance of cast steel is also critical here.

- Metallurgy & Mining: Hauling heavy raw materials or processed metals. While the cargo itself is dense, optimizing the tare weight of the transport equipment enhances overall efficiency and reduces stress on the prime mover.

- Construction & Infrastructure: Transporting construction materials, heavy machinery, or specialized equipment. The robustness and reliable coupling are paramount for safety and operational continuity.

- Water Supply & Drainage / Environmental Services: Specialized tanks and equipment often benefit from the additional payload capacity offered by lightweight components.

- General Freight & Logistics: High-volume, high-frequency logistics operations where cumulative fuel savings and reduced tire/component wear translate into significant operational cost reductions over a fleet's lifetime.

Technical Advantages in Application:

- Energy Saving: A lighter fifth wheel means a lower overall Gross Combination Weight (GCW), directly translating to reduced fuel consumption. Studies show that a 100kg weight reduction can yield up to 0.5% fuel efficiency improvement.

- Corrosion Resistance: Utilizing high-grade cast steel with advanced surface treatments, our fifth wheels exhibit superior resistance to environmental factors, including road salts, moisture, and chemical exposure, crucial for longevity in harsh industrial settings.

- Extended Component Life: Reduced weight puts less strain on the tractor's chassis, suspension, tires, and braking system, leading to longer service intervals and reduced maintenance costs for the entire vehicle.

- Enhanced Maneuverability: Lighter systems can sometimes offer marginal improvements in vehicle handling, especially in complex urban or industrial environments, contributing to safer operations.

- Compliance and Sustainability: Meeting and exceeding regulatory requirements for vehicle weight and emissions, supporting corporate sustainability goals.

Vendor Comparison and Competitive Analysis

When evaluating suppliers for light weight fifth wheel trailers, it is critical to consider not just the upfront fifth wheel price guide, but also factors like product quality, certifications, after-sales support, and long-term cost of ownership. Below is a conceptual comparison:

Fifth Wheel Comparison: Standard vs. Lightweight Optimized

| Feature/Attribute | Standard Cast Steel Fifth Wheel | Light Duty Cast Steel (e.g., LD-37Q) |

|---|---|---|

| Approx. Unit Weight | 180 - 220 kg | 140 - 160 kg (20-30% reduction) |

| Max Vertical Load (SV) | 20,000 - 25,000 kg | 15,000 - 20,000 kg |

| Material Philosophy | Robustness through sheer mass | Strength through optimized design & advanced alloys |

| Fuel Economy Impact | Standard, no specific contribution | Positive, measurable improvement (0.2-0.5% per 100kg saved) |

| Target Application | Heavy-haul, ultra-high loads | General cargo, liquid bulk, refrigerated, medium-duty. |

| Environmental Impact | Higher emissions due to increased fuel consumption | Lower emissions, improved sustainability metrics |

Our long-standing expertise in manufacturing fifth wheel components, coupled with adherence to ISO 9001 and ISO/TS 16949 quality management systems, positions us as an authoritative supplier. We partner with leading truck and trailer OEMs globally, providing millions of reliable units over decades of service.

Customized Solutions and Application Case Studies

Recognizing that every B2B client has unique operational requirements, we offer extensive customized solutions for light weight fifth wheel trailers. This includes tailored mounting heights, specific surface treatments for extreme environments (e.g., marine or desert operations), and integration with bespoke chassis designs. Our engineering team collaborates closely with clients from conceptualization to deployment, ensuring optimal performance and seamless integration.

Case Study 1: Optimized Fuel Efficiency for a Major Logistics Provider

A large intercontinental logistics firm sought to upgrade its fleet of 500 tractor units to improve fuel economy. By replacing their existing heavy-duty fifth wheels with our customized LD-37Q units, which offered a 25% weight reduction per unit, the client achieved substantial annual savings. Over a year, this translated to an average fuel saving of 0.35 liters per 100 km per truck. Cumulatively, this resulted in an estimated annual saving of over €200,000 in fuel costs and a reduction of approximately 500 tons of CO2 emissions across their fleet. The client reported enhanced driver satisfaction due to improved handling and reduced maintenance on associated vehicle components.

Case Study 2: Enhanced Corrosion Resistance for Chemical Transport

A specialized chemical transport company operating in coastal regions faced premature corrosion and failure of their standard fifth wheels due to constant exposure to saline environments and chemical spills. We developed a bespoke version of our light weight fifth wheel incorporating advanced electrophoretic deposition (EPD) and multi-layer polymer coatings. After two years of operation, the customized units showed negligible signs of corrosion compared to their previous equipment, drastically extending service life from 3 years to projected 8+ years and significantly reducing replacement costs and downtime. This solution demonstrated superior resilience against aggressive media, safeguarding both investment and operational integrity.

Trustworthiness: FAQ, Fulfillment, Warranty & Support

Frequently Asked Questions (FAQ)

- Q: What makes a fifth wheel "lightweight"?

A: Lightweight fifth wheels are engineered using advanced alloy steels and optimized design principles (e.g., finite element analysis for material distribution) to reduce mass without compromising strength or safety. They are designed for applications where every kilogram contributes to payload or fuel efficiency. - Q: Are light weight fifth wheel trailers as durable as heavier units?

A: Absolutely. Despite their reduced weight, modern lightweight fifth wheels undergo rigorous testing and are manufactured from high-strength materials. They meet or exceed international safety and performance standards (e.g., ISO, ECE R55), ensuring comparable or superior durability in their intended application range. - Q: What is the typical service life of your LD-37Q fifth wheel?

A: With proper installation and routine maintenance, the Light Duty Cast Steel Fifth Wheel-LD-37Q is designed for a service life exceeding 10 years, even under demanding operational conditions. - Q: How does the fifth wheel price guide for lightweight models compare?

A: While the initial purchase price for a specialized lightweight unit might be slightly higher than a basic heavy-duty model, the long-term operational savings in fuel, tire wear, and reduced maintenance costs often result in a significantly lower Total Cost of Ownership (TCO) over the product's lifespan.

Lead Time and Fulfillment

Our state-of-the-art manufacturing facilities and robust supply chain allow for efficient order fulfillment. Standard models like the LD-37Q typically have a lead time of 4-6 weeks for bulk orders, with expedited options available for urgent requirements. Customized solutions may require additional engineering and production time, generally ranging from 8-12 weeks, depending on complexity. We maintain a global distribution network to ensure timely delivery to your operational hubs.

Warranty Commitments

We stand behind the quality and performance of our light weight fifth wheel trailers with a comprehensive 2-year / 200,000 km warranty (whichever comes first) against manufacturing defects under normal operating conditions. Our warranty covers material and workmanship, providing peace of mind and protecting your investment.

Customer Support and After-Sales Service

Our commitment extends beyond product delivery. We offer dedicated technical support, spare parts availability, and comprehensive maintenance guides. Our global network of certified service partners ensures prompt assistance and genuine replacement parts, minimizing downtime and maximizing the operational lifespan of your fifth wheel components. For technical inquiries, support, or spare parts, please contact our dedicated service line or visit our website for regional contact information.

Conclusion

The strategic adoption of light weight fifth wheel trailers represents a clear path to enhanced operational efficiency, reduced environmental impact, and improved profitability for B2B transportation and logistics entities. Through meticulous engineering, advanced material science, and rigorous quality control, products like the Light Duty Cast Steel Fifth Wheel-LD-37Q offer a compelling solution for the modern fleet. Investing in these sophisticated components is not merely a purchase but a strategic decision to future-proof operations and gain a competitive edge in an increasingly demanding global market.

References

- ISO 8716: Road vehicles – Fifth wheel kingpins – Interchangeability and dimensions. International Organization for Standardization.

- SAE J2227: Fifth Wheel Kingpin Performance - Commercial Vehicles. Society of Automotive Engineers.

- European Commission. (2019). Regulation (EU) 2019/1242 setting CO2 emission performance standards for new heavy-duty vehicles. Official Journal of the European Union.

- ASTM A148/A148M-15: Standard Specification for Steel Castings, High-Strength, for Structural Purposes. ASTM International.

- Transportation Research Board. (2015). Special Report 317: Commercial Truck and Bus Safety Synthesis Program. National Academies of Sciences, Engineering, and Medicine.

-

Fontaine No Slack II Adjustment: Enhancing Trailer Suspension Reliability & Safety

NewsNov.25,2025

-

Fontaine PDF Explained: Industrial Documentation, Specs & Innovation

NewsNov.24,2025

-

Heavy Haul Fifth Wheel – Essential Couplers for Oversized Transport

NewsNov.24,2025

-

Comprehensive Guide to Parts of the Fifth Wheel | Essential Components & Innovations

NewsNov.23,2025

-

Comprehensive Guide to 5th Wheel Parts: Key Components, Vendors & Future Trends

NewsNov.23,2025

-

Comprehensive Guide to Fifth Wheel Grease: Lubrication for Safety and Efficiency

NewsNov.22,2025