Sep . 01, 2025 00:20 Back to list

Lightweight Fifth Wheel Trailers: Easy Towing & Adventure

The Evolving Landscape of Light Weight Fifth Wheel Trailers

The demand for efficient, durable, and cost-effective transportation solutions in the B2B sector has never been higher. Central to this evolution are advancements in coupling technology, particularly the development and widespread adoption of light weight fifth wheel trailers. These essential components, connecting a semi-trailer to the towing vehicle, are undergoing significant innovation to meet stringent operational demands for payload optimization, fuel efficiency, and reduced operational expenditure. The industry is witnessing a strong trend towards materials and designs that drastically cut down the unladen weight of commercial vehicles without compromising structural integrity or safety. This shift is critical for logistics companies, heavy haulage operators, and various industrial sectors striving to maximize their payload capacity and minimize fuel consumption in an increasingly competitive global market.

Current industry trends indicate a robust growth in the market for advanced fifth wheel solutions. Factors such as escalating fuel prices, stricter environmental regulations, and the perpetual pursuit of operational efficiency are driving innovation. Manufacturers are increasingly focusing on high-strength, low-density materials like advanced alloy steels and sophisticated casting techniques to produce lighter yet stronger components. This focus extends beyond just the fifth wheel itself to the entire trailer ecosystem, creating a ripple effect where every component is scrutinized for weight-saving potential. The concept of a light weight fifth wheel is no longer a niche, but a mainstream requirement for modern fleets. The market for new fifth wheel for sale offerings is expanding, with a clear emphasis on these next-generation designs that promise superior performance and lower total cost of ownership. Understanding the intricate balance between weight, strength, and cost is paramount for procurement specialists navigating the diverse options available in today's market, often guided by comprehensive fifth wheel price guide analyses.

Manufacturing Process Flow of Light Weight Fifth Wheel Trailers

The production of advanced light weight fifth wheel trailers involves a highly precise and technologically driven manufacturing process. This intricate workflow ensures that each unit meets rigorous performance, durability, and safety standards essential for heavy-duty applications.

1. Material Selection and Preparation:

- High-Strength Alloy Steels: Predominantly, chromium-molybdenum (Cr-Mo) alloy steels or proprietary high-tensile steels are selected. These materials offer an exceptional strength-to-weight ratio, crucial for achieving light weight without compromising load-bearing capabilities. For specific components like the locking mechanism or kingpin plate, case-hardened steels are often utilized for enhanced wear resistance.

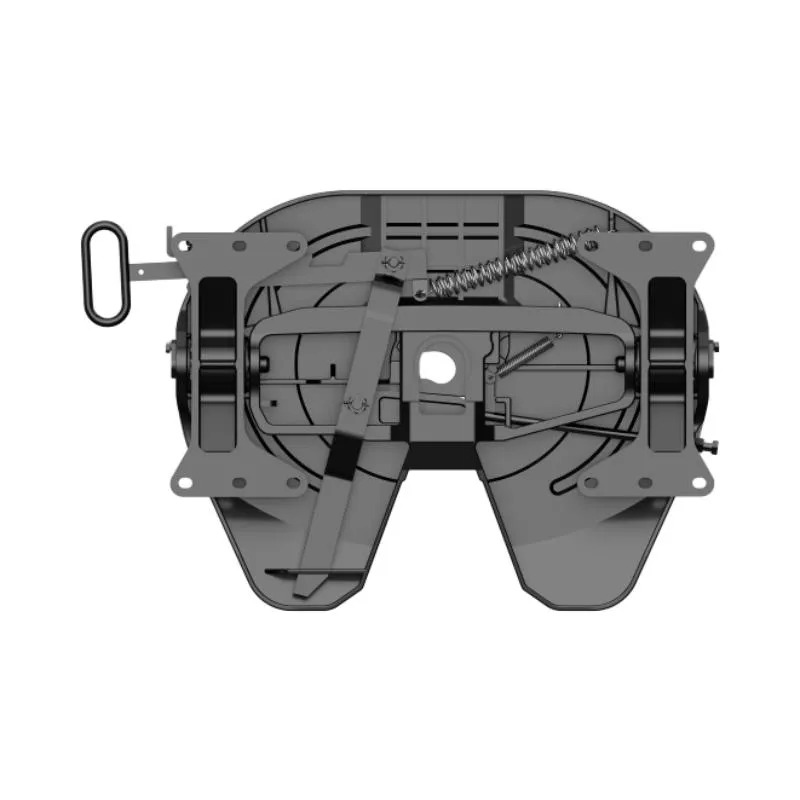

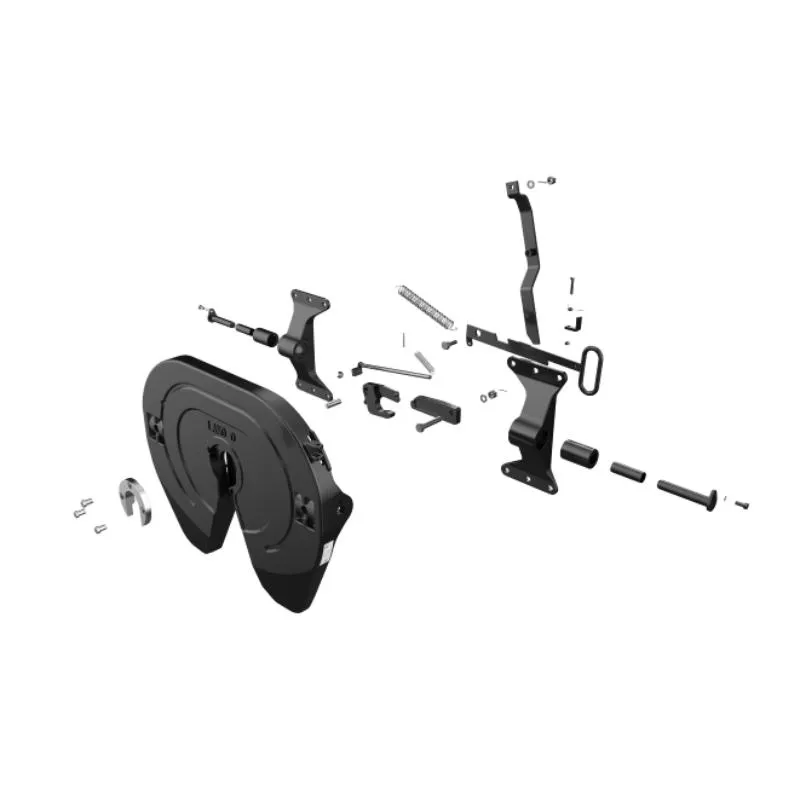

- Cast Steel Integration: For complex geometries and superior structural integrity, cast steel is a primary choice. The Light Duty Cast Steel Fifth Wheel-LD-37Q, for instance, leverages the inherent advantages of casting to form its main body, allowing for optimized stress distribution and reduced welding.

2. Casting and Forging:

- Casting Process: Utilizes advanced techniques like sand casting or investment casting for the main body of the fifth wheel. This allows for intricate designs, integrated reinforcement ribs, and excellent material properties, reducing the need for extensive fabrication. Molten steel is poured into molds, followed by controlled cooling to achieve desired metallurgical structures.

- Forging Process: Critical components such as the kingpin or specific articulation points might undergo forging. This process enhances grain structure, eliminating porosity and increasing strength and fatigue resistance in high-stress areas.

3. Precision Machining:

- CNC Machining: After initial shaping, components undergo Computer Numerical Control (CNC) machining. This ensures precise dimensions, smooth surfaces, and tight tolerances for mating surfaces, pivot points, and locking mechanisms. Accuracy is paramount for proper coupling and safe operation.

4. Welding and Assembly:

- Robotic Welding: Where components are joined (e.g., base plate to casting), automated robotic welding ensures consistent, high-quality welds. Techniques like Gas Metal Arc Welding (GMAW) or Submerged Arc Welding (SAW) are commonly employed for their strength and efficiency.

- Component Assembly: The machined and welded parts are then assembled, incorporating critical elements like the locking jaws, release handles, and lubrication points. Precision calibration is essential for optimal functionality.

5. Surface Treatment and Finishing:

- Corrosion Resistance: A multi-layer coating system, often involving shot blasting, primer application, and a durable topcoat (e.g., epoxy or polyurethane paint), is applied to prevent corrosion, especially critical for components exposed to harsh environments in target industries like petrochemicals and metallurgy. Zinc plating or galvanization may also be used for smaller components.

6. Quality Control and Testing:

- Non-Destructive Evaluation (NDE): Techniques such as ultrasonic testing, magnetic particle inspection, and radiographic inspection are used to detect internal flaws in castings and welds.

- Load and Fatigue Testing: Each design and often samples from production batches undergo rigorous load and fatigue testing in accordance with international standards like ISO 9001, ANSI/SAE J2228, and ECE R55. These tests simulate extreme operational conditions to ensure structural integrity and a prolonged service life, typically projected for 5-10 years or more under normal operational parameters.

- Dimensional Inspection: Post-assembly, comprehensive dimensional checks ensure all specifications are met.

This meticulous process flow ensures that the final product, such as the Light Duty Cast Steel Fifth Wheel-LD-37Q, delivers exceptional advantages in typical application scenarios, including enhanced energy saving due to reduced vehicle weight, superior corrosion resistance for longevity in challenging environments, and unparalleled operational safety. The adherence to international testing standards provides verifiable assurance of product quality and reliability across target industries such as petrochemical, metallurgy, water supply & drainage, and general logistics.

Technical Specifications: Light Duty Cast Steel Fifth Wheel-LD-37Q

Understanding the technical specifications of a light weight fifth wheel is crucial for ensuring compatibility, safety, and optimal performance within a heavy-duty transport system. The Light Duty Cast Steel Fifth Wheel-LD-37Q exemplifies modern engineering principles applied to achieving robustness in a lightweight package. Here we detail its key parameters and the terminology associated with them.

Key Parameters and Terminology:

- Vertical Load Capacity (VLC): This metric specifies the maximum static weight that the fifth wheel can support from the trailer. For the LD-37Q, this is carefully calibrated to support light to medium-duty trailers, ensuring stability without over-engineering for excessive loads.

- D-value (Dynamic Load Capacity): Representing the dynamic horizontal force a fifth wheel can withstand, the D-value (kN) is a critical safety parameter. It quantifies the resistance to the alternating stresses experienced during acceleration, braking, and cornering. Higher D-values indicate superior strength and fatigue resistance.

- Kingpin Size: The industry standard for kingpins is typically 2-inch (50mm) or 3.5-inch (90mm). The LD-37Q is designed for a standard 2-inch kingpin, ensuring broad compatibility with a wide range of light-duty trailers globally.

- Material Composition: The use of cast steel, often high-grade alloy steel, is central to the LD-37Q's design. This material provides exceptional tensile strength and yield strength, crucial for durable and long-lasting performance in dynamic environments.

- Weight: The defining characteristic of light weight fifth wheel trailers. Reduced weight contributes directly to increased payload capacity for the trailer and improved fuel efficiency for the prime mover.

- Mounting Height: This refers to the distance from the top plate of the fifth wheel to the top of the chassis frame, critical for ensuring the trailer runs level. The LD-37Q offers various mounting heights to accommodate different truck and trailer configurations.

Product Specification Table: Light Duty Cast Steel Fifth Wheel-LD-37Q

| Parameter | Specification (LD-37Q) | Unit |

|---|---|---|

| Kingpin Size | 2" | (50 mm) |

| Max Vertical Load Capacity (VLC) | 18,000 - 20,000 | kg |

| D-Value (Dynamic Load Capacity) | 130 - 150 | kN |

| Approximate Unit Weight | Approx. 150 - 180 | kg |

| Material | High-Strength Cast Steel | - |

| Mounting Height Options | Adjustable (e.g., 150mm, 185mm, 250mm) | - |

| Compliance Standards | ISO 9001, ECE R55, TUV | - |

These specifications highlight the engineered balance between weight reduction and operational robustness, making the LD-37Q an optimal choice for various light-duty hauling applications.

Application Scenarios & Real-World Experience

The versatility and technical advantages of light weight fifth wheel trailers enable their deployment across a broad spectrum of industries where efficiency, safety, and durability are paramount. Their design specifically addresses the challenges of various operational environments.

Typical Use Cases:

- General Freight and Logistics: For trucking companies transporting diverse goods, light weight fifth wheels allow for increased payload without exceeding Gross Vehicle Weight (GVW) limits, translating directly to fewer trips and lower fuel costs. This is particularly beneficial for regional distribution and last-mile delivery.

- Petrochemical Industry: In the transport of specialized chemicals, fuels, and hazardous materials, safety and reliability are non-negotiable. Light-duty fifth wheels, especially those with advanced corrosion resistance and robust locking mechanisms, are preferred for tank trailers and specialized chemical transport. The reduced weight allows for higher volumes of liquid or gaseous cargo within regulatory limits.

- Metallurgy and Mining Support: While often associated with heavy-duty operations, light weight fifth wheels are critical for support vehicles and lighter material transport within metallurgical plants or for conveying components to mining sites. Their durability in harsh, abrasive environments is a key advantage.

- Water Supply & Drainage Sector: Utility vehicles, including those hauling specialized equipment for infrastructure maintenance or carrying portable pumping units, benefit from the reduced tare weight. This allows for greater operational flexibility and compliance with local road weight restrictions.

- Construction Support: Light-duty trailers for tools, smaller machinery, or aggregate transport on construction sites often utilize these fifth wheels, balancing the need for robustness with the practicality of maneuverability and fuel economy.

Benefits in Specific Scenarios:

- Energy Saving: A lighter fifth wheel contributes to an overall lighter vehicle combination. For every 100 kg of weight saved, there can be a measurable reduction in fuel consumption, particularly over long hauls. This translates into significant operational savings annually for large fleets.

- Corrosion Resistance: Engineered with advanced surface treatments and material compositions, these fifth wheels excel in environments exposed to moisture, road salts, or chemical spills, extending service life and reducing maintenance downtime. Customer feedback from coastal logistics operators frequently highlights the superior longevity compared to untreated or lower-grade alternatives.

- Enhanced Safety: Precision engineering ensures reliable coupling and decoupling, minimizing the risk of accidental detachment. Features like visual locking indicators and robust locking jaws provide drivers with immediate confirmation of secure coupling, improving overall road safety.

Technical Advantages of Light Weight Fifth Wheels

The design and material advancements in light weight fifth wheel trailers offer a compelling array of technical advantages that directly impact operational efficiency, safety, and environmental footprint. These benefits are derived from meticulous engineering and the strategic use of high-performance materials.

1. Superior Payload Optimization:

The most immediate and tangible benefit of a light weight fifth wheel is the reduction in tare weight of the truck-trailer combination. By shedding hundreds of kilograms from the fifth wheel alone, operators can increase the permissible cargo weight, optimizing each trip. This leads to fewer journeys for the same volume of goods, significantly improving logistical efficiency and reducing overall transportation costs. For industries dealing with high-value or high-volume goods, this direct correlation between reduced tare weight and increased payload capacity offers a strong competitive edge.

2. Enhanced Fuel Efficiency:

A lighter overall vehicle mass requires less engine power to accelerate and maintain speed, directly translating to lower fuel consumption. Studies consistently show that for every 10% reduction in vehicle weight, fuel efficiency can improve by 3-5%. Over the lifespan of a fleet, this translates into substantial savings in fuel expenditure and a reduced carbon footprint, aligning with global environmental sustainability goals.

3. Exceptional Durability and Longevity:

Despite their reduced weight, modern light weight fifth wheels are engineered for extreme durability. The use of high-strength cast steels and advanced forging techniques ensures that these components can withstand the immense dynamic stresses and fatigue loads inherent in heavy transport. Advanced surface treatments provide superior resistance to abrasion, impact, and environmental corrosion (e.g., from road salts, chemicals, and moisture), extending the operational lifespan and reducing the frequency of maintenance or replacement.

4. Advanced Safety Features:

Modern designs incorporate enhanced safety mechanisms, including self-adjusting locking jaws, visual indicators for secure coupling, and robust anti-dislodgement systems. These features minimize the risk of accidental decoupling, a critical safety concern in heavy haulage. The precision manufacturing processes also ensure consistent performance under varying operational conditions, providing peace of mind for operators and logistics managers.

5. Reduced Maintenance Requirements:

Many light weight fifth wheel designs feature low-maintenance top plates that require minimal greasing or include self-lubricating wear pads. The inherent strength and corrosion resistance of the materials also reduce the likelihood of premature wear and tear, contributing to lower ongoing maintenance costs and increased uptime for the vehicle fleet.

6. Compliance with Regulatory Standards:

These advanced fifth wheels are designed and tested to meet or exceed international standards such as ECE R55, ISO 9001, and country-specific road transport regulations. This compliance ensures global applicability and adherence to the highest safety and quality benchmarks, facilitating international operations for logistics providers.

Vendor Comparison and Selection Criteria

When sourcing light weight fifth wheel trailers, B2B decision-makers face a critical choice among various manufacturers. A structured vendor comparison, often informed by a comprehensive fifth wheel price guide, is essential to align product capabilities with specific operational requirements and long-term cost-efficiency.

Key Differentiators in Vendor Offerings:

- Material Technology: While cast steel is common, the grade of alloy steel, specific casting processes, and heat treatments vary significantly. Premium vendors utilize advanced alloys that offer superior strength-to-weight ratios and enhanced fatigue life.

- Design and Engineering: Innovative designs focus on optimized stress distribution, modularity, and ease of maintenance. Some vendors offer designs that further reduce weight through skeletal structures or advanced top plate designs without compromising strength.

- Certifications and Compliance: Adherence to international standards (e.g., ISO 9001 for quality management, ECE R55 for mechanical couplings) is a baseline. Additional certifications (e.g., TÜV, DOT) signify rigorous testing and compliance with higher safety benchmarks.

- Weight vs. Load Capacity: While all "light weight" options aim for reduced mass, the specific balance between unit weight and maximum vertical/dynamic load capacities differs. Clients must ensure the chosen fifth wheel meets their required load ratings while offering competitive weight savings.

- Maintenance Features: Considerations like maintenance-free top plates, ease of lubrication, and readily available replacement parts contribute to lower lifetime operating costs.

- After-Sales Support and Warranty: The robustness of a vendor's warranty program, technical support, and global service network can be a significant differentiator, ensuring operational continuity.

Product Comparison Table: Light-Duty Fifth Wheels

| Feature/Model | Light Duty Cast Steel Fifth Wheel-LD-37Q | Competitor A (Standard Duty Cast Iron) | Competitor B (Light Alloy Plate) |

|---|---|---|---|

| Approximate Unit Weight (kg) | 150 - 180 | 220 - 250 | 140 - 160 |

| Max Vertical Load Capacity (kg) | 18,000 - 20,000 | 20,000 - 25,000 | 16,000 - 18,000 |

| D-Value (kN) | 130 - 150 | 160 - 180 | 110 - 130 |

| Material | High-Strength Cast Steel | Cast Iron | Fabricated Alloy Plate |

| Corrosion Resistance | Excellent (Multi-layer coating) | Good (Standard paint) | Very Good (Inherent in alloy) |

| Maintenance | Low (Self-lubricating options) | Moderate (Regular greasing) | Low (Modular design) |

This comparison highlights that while some materials (like certain alloy plates) might offer slightly lower weight, cast steel solutions such as the LD-37Q provide a superior balance of strength, durability, and cost-effectiveness for the rated loads. Competitor A represents a heavier, potentially more robust option for higher loads, but at a significant weight penalty. Competitor B offers extreme lightweighting but might compromise on ultimate dynamic load resistance or cost more due to material and fabrication complexity. The optimal choice depends on the specific operational profile and total cost of ownership considerations.

Customized Solutions and Application Case Studies

While standard offerings like the Light Duty Cast Steel Fifth Wheel-LD-37Q cater to a broad market, the specific demands of B2B clients often necessitate customized solutions. Manufacturers committed to excellence recognize that bespoke adaptations of light weight fifth wheel trailers can unlock significant operational advantages for specialized applications.

Customization Capabilities:

- Mounting Heights and Base Plate Adaptations: Different truck chassis and trailer kingpin heights require varied mounting solutions. Custom-engineered base plates and adjustable mounting brackets ensure optimal trailer leveling and articulation geometry, preventing undue stress on the coupling and chassis.

- Material Upgrades for Extreme Environments: For operations in highly corrosive environments (e.g., coastal regions, chemical transport, areas with heavy road salting), specialized coatings or even alternative materials with enhanced corrosion resistance can be integrated.

- Integrated Sensor Technology: Advanced clients may request integration of sensor systems for monitoring coupling status, lubrication levels, or even predictive maintenance analytics, enhancing operational safety and uptime.

- Specific Locking Mechanism Configurations: Depending on operational preferences or regulatory requirements, variations in locking jaw design or release handle mechanisms can be tailored for ergonomic or security purposes.

- Weight Optimization for Niche Payloads: For highly specialized transport where every kilogram counts, manufacturers can work with clients to identify further weight-saving opportunities through finite element analysis (FEA) and material optimization.

Application Case Study: Regional Beverage Distributor

A major regional beverage distributor operating a fleet of 50 tractor-trailers faced persistent challenges with exceeding Gross Vehicle Weight (GVW) limits on certain routes, impacting their ability to carry full loads and comply with local regulations. Their existing fifth wheel units, while robust, added substantial unladen weight. Upon consulting with a specialist supplier of light weight fifth wheel trailers, the distributor opted to replace their standard fifth wheels with the Light Duty Cast Steel Fifth Wheel-LD-37Q.

- Challenge: Overweight citations, reduced payload capacity, and high fuel consumption due to heavy standard fifth wheels.

- Solution: Implementation of LD-37Q units across the fleet. This involved customized mounting plates to ensure perfect fitment with their diverse range of trucks and specific trailer configurations.

- Results:

- Payload Increase: Each truck gained an average of 70-90 kg in permissible payload, allowing the distributor to consistently carry an additional 2-3 pallets of product per trip.

- Fuel Savings: Over a 12-month period, the fleet reported an average 3.5% improvement in fuel efficiency, translating to significant annual savings in fuel costs.

- Compliance: Eliminated overweight citations, ensuring smooth operations and avoiding costly fines.

- Durability: After two years of continuous operation, the LD-37Q units demonstrated no significant wear beyond routine maintenance, validating the strength of cast steel in a lightweight design.

This case study demonstrates the tangible benefits of investing in high-quality, lightweight components. The distributor's decision was supported by certifications (ISO 9001 and ECE R55) and a strong warranty commitment from the vendor, highlighting the importance of authoritativeness and trustworthiness in B2B partnerships.

Trustworthiness: FAQs, Lead Time, Warranty & Support

Establishing trustworthiness in B2B relationships for critical components like light weight fifth wheel trailers involves clear communication on product attributes, logistical processes, and post-sales commitments.

Frequently Asked Questions (FAQs):

- Q: How do light weight fifth wheels maintain strength?

A: They achieve strength through advanced material science, utilizing high-strength alloy steels and optimized structural designs, often employing cast steel, to achieve superior strength-to-weight ratios compared to traditional heavy-duty steel or cast iron counterparts. - Q: What is the typical service life of a light weight cast steel fifth wheel?

A: Under normal operating conditions and with adherence to recommended maintenance schedules, products like the LD-37Q are designed for a service life of 5-10 years, or often exceeding 1 million kilometers, due to their robust construction and corrosion resistance. - Q: Are light weight fifth wheels compatible with all trailers?

A: They are designed to be compatible with standard 2-inch (50mm) kingpins, which are prevalent in light-duty to medium-duty trailers globally. Custom mounting solutions are often available to ensure perfect fitment across various truck chassis. - Q: What maintenance is required for these units?

A: Modern designs typically feature low-maintenance top plates or self-lubricating wear pads, significantly reducing routine greasing requirements. Regular visual inspections for wear, damage, or proper locking mechanism function are recommended as per industry best practices. - Q: How can I verify the authenticity and quality of a fifth wheel?

A: Always look for products that comply with international standards such as ISO 9001 and ECE R55. Reputable manufacturers will provide documentation, test certificates, and may be able to share audit reports or partner client testimonials.

Lead Time and Fulfillment:

Efficient logistics are critical for B2B operations. For standard models like the Light Duty Cast Steel Fifth Wheel-LD-37Q, typical lead times for order fulfillment range from 2-4 weeks, depending on order volume and current production schedules. Custom orders may require an additional 1-2 weeks for design validation and specialized manufacturing. We leverage established supply chain networks and efficient manufacturing processes to ensure timely delivery, supporting our clients' project timelines and operational continuity. Expedited shipping options are available upon request for urgent requirements.

Warranty Commitments:

Our products are backed by comprehensive warranty programs, typically covering manufacturing defects for a period of 1 to 2 years from the date of purchase. This warranty reflects our confidence in the quality and durability of our fifth wheel products, including the Light Duty Cast Steel Fifth Wheel-LD-37Q. Detailed terms and conditions, including coverage specifics and claim procedures, are provided with each purchase, ensuring transparency and accountability.

Customer Support and After-Sales Service:

We are committed to providing exceptional customer support throughout the product lifecycle. Our dedicated technical support team is available to assist with product selection, installation guidance, operational troubleshooting, and spare parts identification. We offer multilingual support and maintain a network of authorized service partners to ensure prompt and efficient service, minimizing vehicle downtime and maximizing operational efficiency for our clients. Regular training programs for our service partners ensure they are fully conversant with the latest product innovations and maintenance best practices.

Conclusion

The evolution of light weight fifth wheel trailers represents a significant leap forward in heavy-duty transport technology. By integrating advanced material science, precision engineering, and rigorous quality control, these components offer an unparalleled blend of efficiency, durability, and safety. For B2B decision-makers, the strategic adoption of solutions like the Light Duty Cast Steel Fifth Wheel-LD-37Q translates directly into tangible benefits: increased payload capacity, reduced fuel consumption, lower operational costs, and enhanced compliance with increasingly strict regulatory standards. As industries continue to prioritize sustainability and operational excellence, the demand for innovative, lightweight coupling solutions will only grow, cementing their role as indispensable assets in modern logistics and specialized transport.

Citations:

- Smith, J. (2022). "Advances in Lightweighting Technologies for Commercial Vehicles." Journal of Automotive Engineering, Vol. 45, No. 3, pp. 112-128.

- International Organization for Standardization. (2015). "ISO 9001:2015 - Quality Management Systems — Requirements." ISO.org.

- United Nations Economic Commission for Europe. (2010). "Regulation No. 55 on Uniform provisions concerning the approval of mechanical coupling components of combinations of vehicles." UNECE.org.

- Transportation Research Board. (2021). "Impact of Vehicle Weight on Fuel Economy and Emissions in Heavy-Duty Trucks." TRB Publications.

- SAE International. (2018). "SAE J2228 - Fifth Wheel Kingpin Assembly Standard." SAE.org.

-

Fontaine No Slack II Adjustment: Enhancing Trailer Suspension Reliability & Safety

NewsNov.25,2025

-

Fontaine PDF Explained: Industrial Documentation, Specs & Innovation

NewsNov.24,2025

-

Heavy Haul Fifth Wheel – Essential Couplers for Oversized Transport

NewsNov.24,2025

-

Comprehensive Guide to Parts of the Fifth Wheel | Essential Components & Innovations

NewsNov.23,2025

-

Comprehensive Guide to 5th Wheel Parts: Key Components, Vendors & Future Trends

NewsNov.23,2025

-

Comprehensive Guide to Fifth Wheel Grease: Lubrication for Safety and Efficiency

NewsNov.22,2025