Oct . 06, 2025 00:50 Back to list

Germany Type Suspension for Power Lines: Why Choose Ours?

Germany Type Suspension is a key solution in the manufacturing industry, specifically within automobile manufacturing industry and Manufacturing of automotive parts and accessories. This article explores how Shijiazhuang Land Auto Component Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Germany Type Suspension Overview

- Benefits & Use Cases of Germany Type Suspension in Manufacturing of automotive parts and accessories

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Germany Type Suspension from Shijiazhuang Land Auto Component Ltd.

Germany Type Suspension Overview

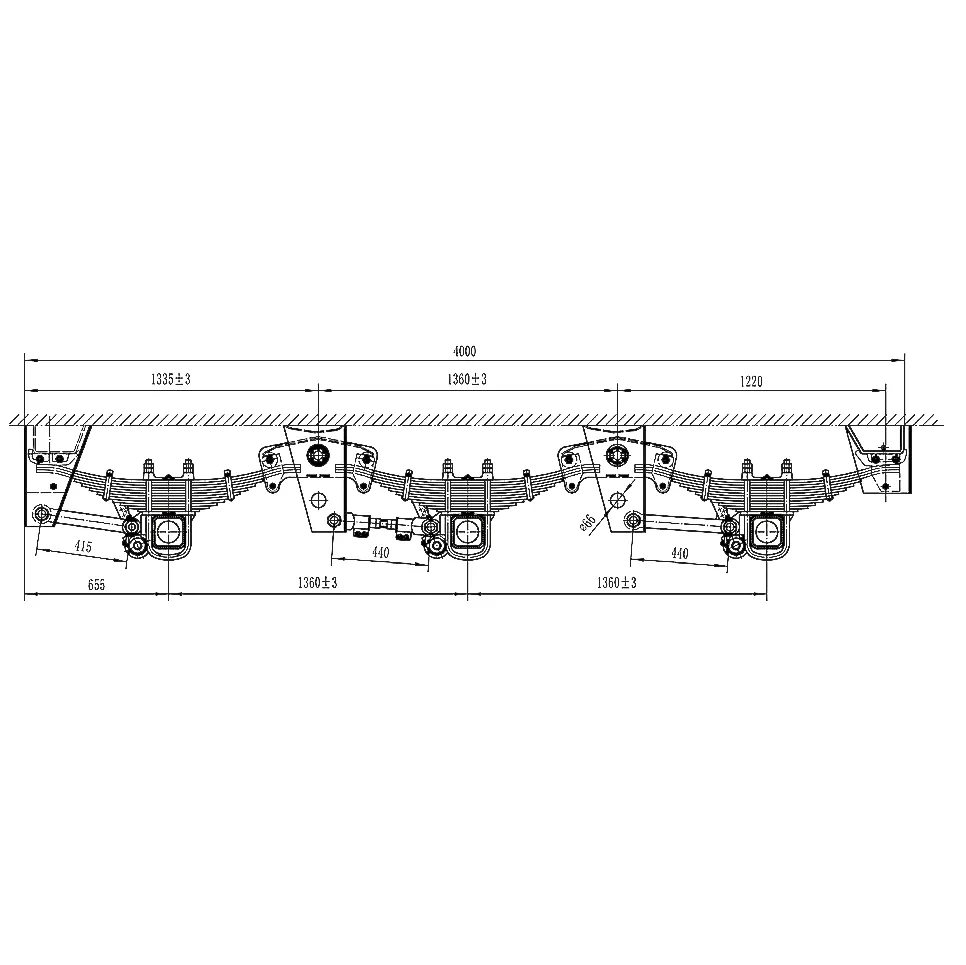

Germany Type Suspension refers to a heavy-duty, mechanically sprung suspension architecture widely adopted on semi-trailers and specialty vehicles across Europe and global export markets. Built for high axle loads, frequent braking cycles, and mixed-road conditions, it typically combines reinforced hangers, equalizers, multi-leaf or parabolic spring packs, torque rods, and precision axle seating to maintain alignment under load. For B2B decision makers in the Manufacturing of automotive parts and accessories, this platform offers a proven balance of robustness, serviceability, and cost control.

Shijiazhuang Land Auto Component Ltd. engineers and supplies Germany Type Suspension assemblies designed for common industry configurations such as tandem and tri-axle sets and typical axle-load classes used by trailer OEMs. The design supports accurate axle parallelism, stable braking response, and predictable tire wear—factors that directly influence fleet uptime and lifecycle cost. Options can include various track widths, brake compatibilities, anti-corrosion finishes, and bushing materials to match route profiles and cargo types. Backed by years of manufacturing experience in automotive components, Shijiazhuang Land Auto Component Ltd. delivers consistent quality and reliable lead times to OEMs and distributors worldwide.

Benefits & Use Cases of Germany Type Suspension in Manufacturing of automotive parts and accessories

In the Manufacturing of automotive parts and accessories, Germany Type Suspension is a preferred choice for trailer builders producing flatbeds, tippers, tankers, container111 chassis, and lowbeds. Its mechanical simplicity, coupled with robust metallurgy and careful hanger geometry, ensures dependable performance in heavy-haul, regional distribution, and construction-site operations. The suspension’s stable axle tracking helps protect cargo integrity, while consistent ride characteristics support braking efficiency and predictable steering behavior for the tractor-trailer combination.

Key advantages include durable springs and equalizers, wear-resistant bushings, and high-strength steel hangers that handle shock loads without compromising alignment. The modular layout simplifies assembly on the production line and makes field service faster—important for OEMs and fleet maintainers alike. Shijiazhuang Land Auto Component Ltd.’s engineering team collaborates with B2B buyers to define specifications that fit local road conditions and regulatory norms, from component coatings for corrosion resistance to bolt patterns that streamline spare parts logistics. The result is a Germany Type Suspension package that integrates smoothly into existing chassis designs and supports repeatable, scalable manufacturing.

Cost, Maintenance & User Experience

Total cost of ownership is a central metric for B2B procurement. Germany Type Suspension delivers value through long service life, predictable maintenance, and accessible spare parts. Its mechanical architecture reduces dependence on complex pneumatics or electronics, lowering initial costs and simplifying diagnostics. Fleet managers often prioritize components that minimize tire wear and downtime; stable axle alignment and rugged bushings contribute directly to these goals.

Recommended practices include periodic torque checks on U-bolts and hanger fasteners, bushing inspection, and spring wear monitoring in line with fleet maintenance intervals. This proactive approach helps detect early signs of misalignment that could increase tire and fuel costs. Users in the automobile manufacturing industry report that modular components and clear assembly diagrams accelerate both OEM line-fit and aftermarket service. Shijiazhuang Land Auto Component Ltd. supports customers with documentation, parts availability, and responsive technical consultation—helping buyers achieve a favorable ROI by extending component life and reducing unplanned maintenance events over the trailer’s operating cycle.

Sustainability & Market Trends in manufacturing

Sustainability in manufacturing emphasizes durability, rebuildability, and material efficiency. Germany Type Suspension aligns with these goals through long-life components and replaceable wear parts that support refurbishment instead of full replacement. For trailer OEMs, a durable suspension reduces scrap rates and service calls, while for fleets, longer intervals between component changes mean less waste and fewer logistics disruptions. Protective coatings and thoughtful materials selection further extend corrosion resistance in challenging climates.

Market trends point to tighter safety expectations, closer attention to lifecycle emissions, and the need for supply chain resilience. Shijiazhuang Land Auto Component Ltd. responds with robust engineering, consistent process control, and product options that help OEMs build lighter, longer-lasting chassis without compromising strength. By focusing on reliability and maintainability, the company supports a practical path toward lower lifecycle impact—helping trailer builders and parts distributors meet customer sustainability objectives while maintaining competitive total cost.

Conclusion on Germany Type Suspension from Shijiazhuang Land Auto Component Ltd.

For B2B decision makers in the automobile manufacturing industry and the Manufacturing of automotive parts and accessories, Germany Type Suspension offers a proven blend of durability, serviceability, and cost efficiency. Shijiazhuang Land Auto Component Ltd. combines engineering know-how with dependable production to deliver suspension assemblies that integrate seamlessly into OEM workflows and stand up to real-world loads. Ready to specify your next program?

Contact us: email: info@land-d.cn

Visit our website: https://www.landfifthwheel.com

-

Fontaine No Slack II Adjustment: Enhancing Trailer Suspension Reliability & Safety

NewsNov.25,2025

-

Fontaine PDF Explained: Industrial Documentation, Specs & Innovation

NewsNov.24,2025

-

Heavy Haul Fifth Wheel – Essential Couplers for Oversized Transport

NewsNov.24,2025

-

Comprehensive Guide to Parts of the Fifth Wheel | Essential Components & Innovations

NewsNov.23,2025

-

Comprehensive Guide to 5th Wheel Parts: Key Components, Vendors & Future Trends

NewsNov.23,2025

-

Comprehensive Guide to Fifth Wheel Grease: Lubrication for Safety and Efficiency

NewsNov.22,2025