Oct . 06, 2025 00:20 Back to list

Need a 5th wheel bumper kit—heavy-duty, easy install?

A Field-Tested Look at 5th Wheel Bumper Kits (and Why Fleets Care)

If you’ve ever listened to a tired fifth wheel clatter over a loading ramp, you already know why a 5th wheel bumper kit matters. The humble bumper pads tame shock, reduce metal-to-metal slap, and keep the kingpin and jaw behaving. I’ve spent enough hours with fleet techs to say this: a fresh set of bumpers often quiets a truck more than a new radio.

Today’s example comes from Shijiazhuang City, Hebei, China—LAND D’s “High Quality JOST tape Fifth wheel J3800 repair kits.” On paper: trailer parts for JOST-style applications, color black, aimed squarely at shops that rebuild JSK-series plates. In practice: it’s a no-drama solution for fleets rotating through scheduled fifth wheel overhauls every 12–24 months, depending on routes and abuse.

What’s Inside and Why It Works

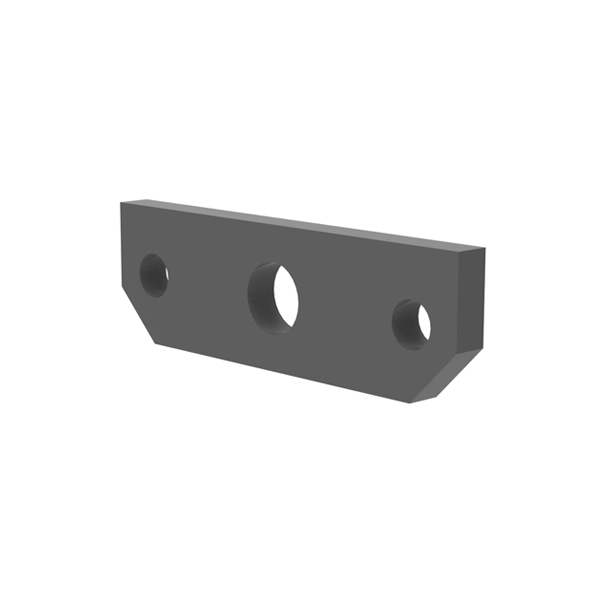

The kit’s elastomer pads (typically NBR or PU) sit on a steel backing, absorbing impact and cutting vibration. Many customers say cab noise drops noticeably after install—nothing lab-grade, but the difference is obvious to drivers. In fleet garages, it seems that these pads also help tame premature jaw wear by preventing harsh rebounds.

| Specification | Typical Value (≈ / ranges) |

|---|---|

| Compatibility | JOST JSK series (J3800 repair set context); verify plate model before ordering |

| Elastomer Hardness | Shore A ≈ 80 ± 5 (ASTM D2240) — real-world feel varies with temperature |

| Temperature Window | ≈ -40 °C to +100 °C (duty dependent) |

| Corrosion Defense | Steel backing with protective finish; ISO 9227 salt spray ≈ 72–120 h |

| Service Life | Around 18–36 months in mixed regional haul; severe duty may be shorter |

Process, Testing, and Standards

Materials are compression-molded elastomer bonded to a machined or stamped steel plate, followed by deburring, adhesive cure, and dimensional checks. Sampling often includes hardness (ASTM D2240), bond integrity, and salt-spray validation (ISO 9227). Coupling systems target ECE R55 conformity and strength guidance per SAE J2638, though certifications are vendor-specific—ask for certs or test reports with the lot.

Where It Fits in the Real World

Use cases: long-haul tractors, intermodal yards, tanker fleets (careful with chemical exposure), logging trailers, municipal snow routes. A Midwest fleet manager told me they cut nuisance rattles by “a good 30%” after swapping a tired set—anecdotal, sure, but it tracks with what technicians report after routine fifth wheel rebuilds that include a 5th wheel bumper kit.

Vendor Snapshot: LAND D vs. Alternatives

| Vendor | Core Material | Certs (≈) | Lead Time | Customization | Price Band |

|---|---|---|---|---|---|

| LAND D (Hebei) | NBR/PU + steel backing | ISO 9001 (manufacturer-level, confirm) | ≈ 10–25 days | Hardness, color, logo | Value/Mid |

| Import Generic A | Rubber blend | Varies; limited docs | Stock-dependent | Minimal | Low |

| OEM Dealer B | OEM-grade elastomer | OEM documentation | Fast (local) | OEM-specific | High |

Installation and Custom Options

Install is straightforward: clean the plate, dry-fit, then torque hardware per the JOST manual (often M10 class 10.9 fasteners; follow OEM spec). LAND D can tweak durometer, dimensions, even branding. For fleets standardizing on a 5th wheel bumper kit, this helps lock in consistent driver feel across tractors.

Takeaway

It’s not flashy, but a quality 5th wheel bumper kit is cheap insurance for smoother coupling and less noise. The LAND D J3800-style kit hits the practicality notes—materials, testing, reasonable lead times—and, to be honest, that’s what keeps trucks earning.

References

-

Fontaine No Slack II Adjustment: Enhancing Trailer Suspension Reliability & Safety

NewsNov.25,2025

-

Fontaine PDF Explained: Industrial Documentation, Specs & Innovation

NewsNov.24,2025

-

Heavy Haul Fifth Wheel – Essential Couplers for Oversized Transport

NewsNov.24,2025

-

Comprehensive Guide to Parts of the Fifth Wheel | Essential Components & Innovations

NewsNov.23,2025

-

Comprehensive Guide to 5th Wheel Parts: Key Components, Vendors & Future Trends

NewsNov.23,2025

-

Comprehensive Guide to Fifth Wheel Grease: Lubrication for Safety and Efficiency

NewsNov.22,2025