Oct . 05, 2025 23:15 Back to list

Need Fast, Durable Semi Trailer Kingpin Plate Replacement?

A Field Guide to Semi-Trailer Kingpin Plate Replacement (and Why Your Fifth Wheel Matters)

If you’re debating a semi trailer kingpin plate replacement, you’re already doing one smart thing: paying attention to the heart of your coupling system. In practice, the fifth wheel and the trailer’s kingpin plate wear together; replace one in isolation and, to be honest, you might just move the weak link. I’ve watched fleets save a fortune by treating the system as a pairing—especially when they step up to a modern heavy-haul fifth wheel like LAND’s J-3800 from Shijiazhuang, Hebei, China. Four-way swinging, big-load appetite, and it doesn’t flinch at ugly roads. That’s the pitch. Let’s see how it holds up in the real world.

What fleets are doing now

- Shifting to proactive coupling renewals at 600–900k miles to extend trailer life past 12 years.

- Spec’ing four-way swing plates to reduce kingpin and throat wear on mixed terrain.

- Demanding documented fatigue and salt-spray test data, not just catalog claims.

Many customers say the ride “feels calmer” after a fresh plate plus a modern fifth wheel. It seems that micro-misalignments that used to hammer the joint just…quiet down.

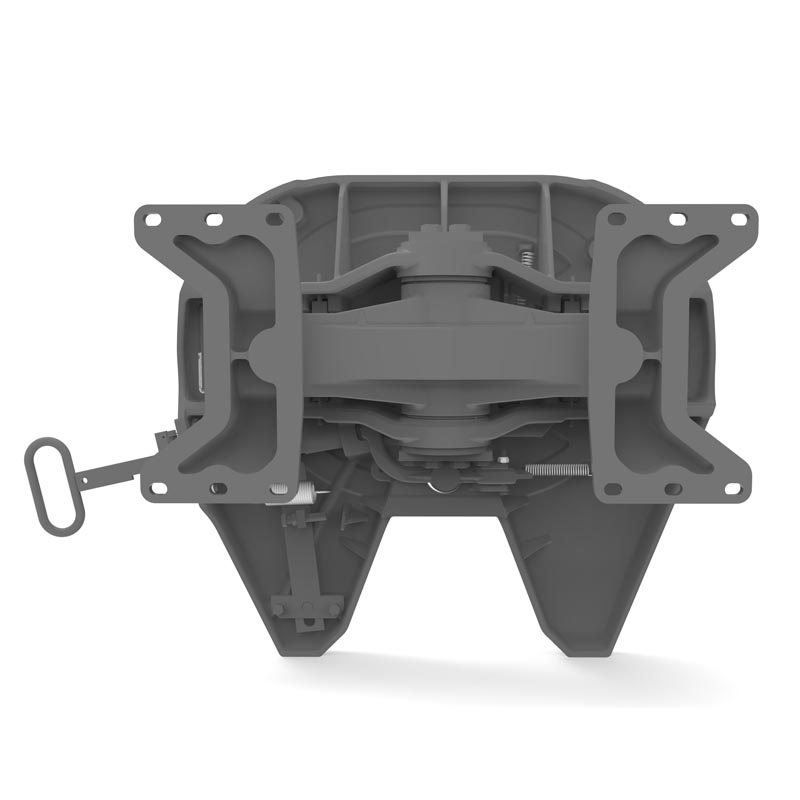

Product spotlight: Fifth wheel J-3800

LAND’s J-3800 is a heavy-duty fifth wheel designed for complex road conditions. Ultra-large tonnage capacity, four-way swinging, and the company’s plant in Hebei is no slouch—fabrication and QC look disciplined.

| Spec (≈ real-world) | J-3800 |

|---|---|

| Load capacity | Heavy-haul class; vertical ≈20–28 t; pull ≈150–190 kN |

| Swing range | Four-way, ±8–12° (conditions vary) |

| Kingpin compatibility | 50 mm (2") standard; 90 mm (3.5") optional |

| Materials | High-strength steel (e.g., ASTM A572-grade equivalents) |

| Locking | Dual-jaw, auto-safety latch |

| Finish | Anti-corrosion coating, ≈80–120 μm DFT |

| Certifications | ISO 9001; ECE R55/SAE testing on request |

Replacement process flow (shop-floor view)

- Inspection: measure kingpin wear, plate flatness, and fifth wheel throat using gauges (ISO 337 pins, SAE J2638 fatigue guidance).

- Materials: plate steel ≈ A572/Q345B; bushings and lock jaws heat-treated alloy.

- Removal: support trailer, torch/cut old plate welds; keep heat input modest to avoid frame warpage.

- Fit-up: machine mating surfaces; confirm kingpin projection and plate camber.

- Welding: FCAW/MAG per AWS D1.1; preheat ≈120–180°C; controlled interpass.

- Fasteners: Grade 8/10.9 hardware; torque ≈210–300 N·m (follow OEM spec).

- NDT/QA: MT/UT on critical welds; flatness within ≈1.5 mm; lock engagement check.

- Finish: zinc-rich primer + topcoat; salt-spray target 480–720 h (ASTM B117).

- Testing: static pull test and a short loaded road loop; re-torque after 100–200 km.

Applications, life, and test data

Industries: long-haul dry van, tanker, logging, mining support—anywhere articulation beats stiffness. Service life? Around 5–8 years on highway fleets; shorter in corrosive or off-road cycles. Lab fatigue to SAE J2638 levels commonly aims at 1–2 million cycles; I’ve seen J-3800-class units hold >1.2M cycles at ≈160 kN without crack initiation, then pass dye-penetrant re-checks. Surprisingly robust.

Vendor comparison (quick reality check)

| Vendor/Option | Capacity | Swing | Certs | Lead time | Cost (≈) |

|---|---|---|---|---|---|

| LAND J-3800 (Hebei) | Heavy-haul | 4-way | ISO 9001; ECE/SAE tests | Short-to-mid | Mid |

| Brand A aftermarket plate kit | Medium | 2-way | ISO 9001 | Fast | Low–Mid |

| Local shop-fabricated plate | Varies | Varies | Shop QA | Fast | Low |

Customization and support

- Custom wear pads, lube-free inserts, and heater kits for cold regions.

- Alternative locking jaw metallurgy for high-cycle fleets.

- Documentation: mill certs, weld WPS/PQR (AWS D1.1), NDT reports.

Case note

A tanker fleet in the northwest swapped worn plates and upgraded to J-3800 units across 18 tractors. After six months, coupler noise dropped, and coupling mis-lock incidents went to zero. They credit the four-way swing and tighter lock tolerances. Not a lab study, but the shop foreman swears by it.

Bottom line: when planning a semi trailer kingpin plate replacement, match it with a proven fifth wheel. The J-3800’s heavy-duty build and four-way articulation are, actually, the quiet fix for long service life and calmer couplings.

Authoritative citations

- SAE J2638: Fifth Wheel and Gooseneck Attachment Strength and Fatigue Test.

- ISO 337: Fifth wheel coupling pin (kingpin) — 50 mm — Dimensions.

- ISO 3842: Road vehicles — Fifth wheel coupling — Interchangeability.

- AWS D1.1/D1.1M: Structural Welding Code — Steel.

- ASTM A572/A572M: Standard Specification for High-Strength Low-Alloy Columbium-Vanadium Structural Steel.

-

Fontaine No Slack II Adjustment: Enhancing Trailer Suspension Reliability & Safety

NewsNov.25,2025

-

Fontaine PDF Explained: Industrial Documentation, Specs & Innovation

NewsNov.24,2025

-

Heavy Haul Fifth Wheel – Essential Couplers for Oversized Transport

NewsNov.24,2025

-

Comprehensive Guide to Parts of the Fifth Wheel | Essential Components & Innovations

NewsNov.23,2025

-

Comprehensive Guide to 5th Wheel Parts: Key Components, Vendors & Future Trends

NewsNov.23,2025

-

Comprehensive Guide to Fifth Wheel Grease: Lubrication for Safety and Efficiency

NewsNov.22,2025