Oct . 29, 2025 00:20 Back to list

Semi Trailer Kingpin Plate Replacement | OEM-Grade & Fast

Semi Trailer Kingpin Plate Replacement is a key solution in the manufacturing industry, specifically within automobile manufacturing industry and Manufacturing of automotive parts and accessories. This article explores how Shijiazhuang Land Auto Component Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Semi Trailer Kingpin Plate Replacement Overview

- Benefits & Use Cases of Semi Trailer Kingpin Plate Replacement in Manufacturing of automotive parts and accessories

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Semi Trailer Kingpin Plate Replacement from Shijiazhuang Land Auto Component Ltd.

Semi Trailer Kingpin Plate Replacement Overview

The kingpin plate (also called the upper coupler or bolster plate) is the critical interface between a trailer and the tractor’s fifth wheel. Over time, this plate—and the kingpin itself—can wear due to high loads, impact events, and thousands of coupling cycles. Semi Trailer Kingpin Plate Replacement restores structural integrity, maintains safe coupling with the fifth wheel jaws, and ensures stable handling and braking. In OEM production and fleet remanufacturing, a properly engineered replacement plate reduces coupling slack, prevents abnormal fifth wheel wear, and minimizes the risk of unplanned downtime.

From a technical perspective, replacement assemblies typically use high-strength, low-alloy steel, robotic welding, and precise machining of the 2" (50 mm) or 3.5" (90 mm) kingpin to meet common ISO and SAE dimensional standards. Options include wear liners, greaseless surfaces, corrosion-resistant coatings, and compatibility with security devices such as a semi trailer kingpin lock. Shijiazhuang Land Auto Component Ltd.—manufacturer of the Land fifth wheel range—builds couplers and related components to rigorous quality controls, offering reliable fit-up with common trailer frame geometries and consistent performance under heavy-duty loads.

Benefits & Use Cases of Semi Trailer Kingpin Plate Replacement in Manufacturing of automotive parts and accessories

In the automotive parts and accessories value chain, kingpin plate replacement supports multiple use cases: OEM trailer assembly lines, contract manufacturing for export markets, fleet mid-life overhauls, and specialized trailers hauling stamping dies, engines, or high-value components. Precise coupling reduces shock loads when maneuvering in plants and on test tracks, improving cargo protection and driver confidence. For integrators coordinating chassis, suspension, and landing gear, a dimensionally consistent plate streamlines jigging and reduces rework, while aligning with solutions from leading semi trailer landing gear manufacturers.

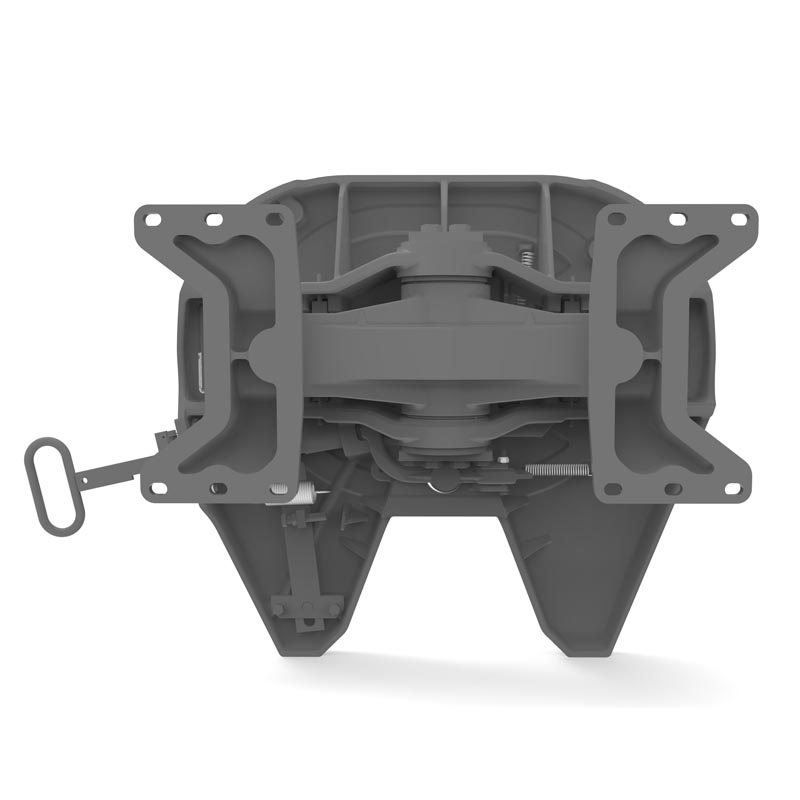

Key advantages include tighter tolerances around the kingpin neck to limit chucking, hardened wear surfaces for longer service intervals, and coatings that resist corrosion from winter road treatments. When paired with Land’s robust fifth wheel (see the J-3800 model), fleets gain predictable engagement, smooth release, and lower jaw and plate wear. Shijiazhuang Land Auto Component Ltd. combines metallurgy expertise with process control to deliver assemblies that integrate cleanly with fifth wheels and security accessories—such as a semi trailer kingpin lock—enhancing both uptime and asset protection.

Cost, Maintenance & User Experience

Total cost of ownership for Semi Trailer Kingpin Plate Replacement is driven by three factors: downtime, wear life, and maintenance frequency. A high-grade plate with a correctly machined kingpin typically extends service by multiple years under mixed regional haul, while greaseless or low-friction liners reduce lube consumption and cleanup. By restoring proper coupling geometry, fleets also prolong fifth wheel jaw life—important when the tractor side is a premium coupler like Land’s J-3800—avoiding secondary component costs. The ROI comes from fewer roadside events, faster coupling, and lower inspection variance during PM checks.

Best practices include regular visual and NDT inspections for cracks around the kingpin weld, measuring kingpin wear, checking plate flatness, and ensuring correct fastener torque to the trailer crossmembers. Customers in the automobile manufacturing industry report smoother yard movements, less coupling shock on sensitive cargo, and reduced rework time at assembly docks after retrofitting with quality plates. Shijiazhuang Land Auto Component Ltd. supports technicians with clear installation guidance and compatibility data, helping maintenance teams complete swaps efficiently and return equipment to service with confidence.

Sustainability & Market Trends in manufacturing

Sustainability pressures and evolving regulations are reshaping trailer coupling components. High-strength steels and optimized plate geometries help reduce tare weight, contributing to lower fuel consumption and CO2 per kilometer. Greaseless surfaces and long-life liners reduce lubricant use and runoff risk, while rebuildable designs support circularity through refurbishment rather than full replacement. For global fleets, alignment with widely recognized standards supports cross-border compliance and simplifies asset redeployment between regions and business units.

Shijiazhuang Land Auto Component Ltd. is investing in clean production practices, such as robotic welding to minimize spatter and rework, targeted heat treatment for consistent hardness, and durable finishes that extend corrosion resistance and service intervals. Packaging choices prioritize recyclable materials, and machining scrap is routed back into certified recycling streams. As the market adopts smarter yard operations, pairing robust kingpin plates with secure coupling (and accessories like a semi trailer kingpin lock) positions fleets for safer, greener, and more efficient logistics across the automotive supply chain.

Conclusion on Semi Trailer Kingpin Plate Replacement from Shijiazhuang Land Auto Component Ltd.

For OEMs, integrators, and fleets in the automobile manufacturing ecosystem, Semi Trailer Kingpin Plate Replacement is a straightforward way to improve coupling reliability, extend component life, and reduce total cost of ownership. With precise fit, robust metallurgy, and compatibility with trusted fifth wheels, Shijiazhuang Land Auto Component Ltd. provides a dependable path to higher uptime and safer operations. Choose a partner known for consistent quality and responsive technical support.

- Contact us: email: info@land-d.cn

- Visit our website: https://www.landfifthwheel.com

- Explore the product: Land J-3800 Fifth Wheel

-

Fontaine No Slack II Adjustment: Enhancing Trailer Suspension Reliability & Safety

NewsNov.25,2025

-

Fontaine PDF Explained: Industrial Documentation, Specs & Innovation

NewsNov.24,2025

-

Heavy Haul Fifth Wheel – Essential Couplers for Oversized Transport

NewsNov.24,2025

-

Comprehensive Guide to Parts of the Fifth Wheel | Essential Components & Innovations

NewsNov.23,2025

-

Comprehensive Guide to 5th Wheel Parts: Key Components, Vendors & Future Trends

NewsNov.23,2025

-

Comprehensive Guide to Fifth Wheel Grease: Lubrication for Safety and Efficiency

NewsNov.22,2025