Ago . 08, 2025 00:20 Back to list

American Type Welding Suspension: Durable & Efficient Systems

In the demanding world of heavy-duty transportation, the integrity and performance of vehicle suspension systems are paramount. They are not merely components; they are critical enablers of safety, efficiency, and operational longevity. Among the forefront of these innovations is the **American Type Welding Series Suspension**, a robust solution engineered to meet the rigorous demands of various industrial applications. This comprehensive guide delves into the essence of this vital technology, exploring its industry significance, intricate technical specifications, diverse application scenarios, and the underlying advantages that set it apart.

Industry Trends and the Evolving Landscape of Heavy-Duty Suspensions

The heavy-duty vehicle industry is experiencing a transformative phase, driven by increasing demands for higher payload capacities, enhanced fuel efficiency, and superior durability. Global supply chain complexities and the imperative for sustainable logistics solutions further accentuate the need for advanced suspension systems. Key trends shaping this sector include:

- Increased Focus on Lightweighting: Utilizing advanced materials and optimized designs to reduce tare weight, thereby increasing payload capacity and improving fuel economy. This often involves high-strength low-alloy (HSLA) steels and sophisticated welding techniques.

- Enhanced Durability and Longevity: Operators require suspensions that can withstand extreme road conditions, heavy loads, and prolonged use without frequent maintenance, minimizing downtime and total cost of ownership (TCO).

- Smart Suspension Systems: While the **American Type Welding Series Suspension** is a mechanical marvel, the broader trend is towards integration with telematics and sensor technologies for real-time monitoring of load, road conditions, and predictive maintenance.

- Sustainability and Eco-friendliness: Design considerations are increasingly incorporating materials with longer lifespans and manufacturing processes with reduced environmental impact.

- Modularity and Customization: The diverse needs of various industries (e.g., oil & gas, construction, logistics) necessitate highly customizable suspension solutions that can be adapted to specific vehicle configurations and operational requirements.

The **American Type Welding Series Suspension** embodies many of these trends, offering a blend of traditional robustness with modern engineering precision, catering specifically to the needs of heavy-duty trailers and vehicles that operate under extreme stress.

Unpacking the **American Type Welding Series Suspension**: Technical Parameters and Specifications

The core strength of the **American Type Welding Series Suspension** lies in its meticulously engineered design and superior material selection. This suspension system is designed for optimal performance in demanding environments, offering unparalleled stability and load distribution.

Key Technical Parameters:

| Parameter | Description | Typical Range/Value for American Type Welding Series Suspension |

|---|---|---|

| Load Capacity per Axle | Maximum weight the suspension can safely support per axle. Critical for legal compliance and operational safety. | 13,000 lbs (5,900 kg) to 25,000 lbs (11,340 kg) per axle, depending on configuration (e.g., single, tandem, tri-axle). |

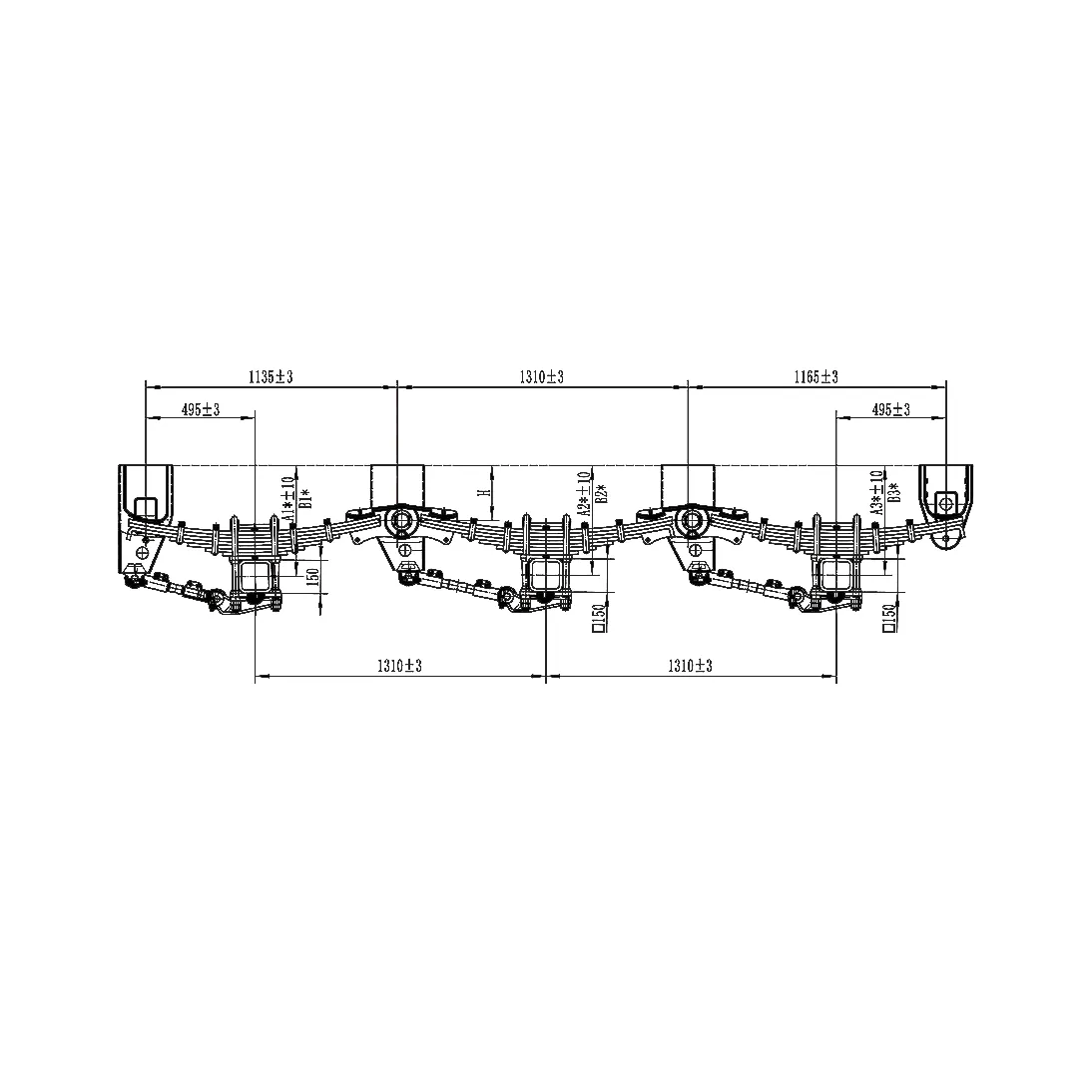

| Axle Spacing Options | The distance between the centers of consecutive axles. Influences weight distribution and turning radius. | 49 inches (1245 mm), 50 inches (1270 mm), 54 inches (1372 mm), 60 inches (1524 mm). |

| Hanger Materials | Primary material used for hangers and equalizers, critical for strength and fatigue resistance. | High-strength low-alloy (HSLA) steel, typically Q345B or equivalent, ensuring superior yield and tensile strength. |

| Spring Type & Size | Number of leaves and dimensions (width, thickness) determine flexibility and load support. | Multi-leaf springs, typically 3.5 inches (90mm) or 4 inches (100mm) wide, with varying leaf counts (e.g., 9-leaf, 10-leaf). |

| Bushings | Components that reduce friction and vibration between moving parts. | Rubber or polyurethane bushings, often maintenance-free or low-maintenance, ensuring long service life. |

| Weight (Approx.) | Overall weight of the suspension system itself. Affects trailer tare weight. | Approximately 500-800 kg per tandem setup, varying with axle count and specific components. |

| Compliance Standards | Adherence to national and international safety and manufacturing standards. | ISO 9001:2015, relevant SAE standards (e.g., SAE J684 for coupling), AWS D1.1 (welding standards). |

| Mounting Options | How the suspension is attached to the trailer frame. | Underslung, overslung, and various weld-on configurations to accommodate different frame designs. |

These parameters underscore the robust design of the **American Type Welding Series Suspension**, ensuring it can safely and efficiently handle the most demanding transport tasks. The selection of HSLA steel, for instance, significantly enhances the strength-to-weight ratio, contributing to both payload optimization and fuel efficiency without compromising structural integrity.

The Meticulous Manufacturing Process of **American Type Welding Series Suspension**

The creation of a reliable **American Type Welding Series Suspension** is a testament to precision engineering, advanced manufacturing techniques, and stringent quality control. The process ensures each component meets the highest standards for durability and performance. Below is a detailed breakdown of the typical manufacturing workflow:

Manufacturing Process Flow:

- Material Sourcing and Preparation:

- Material: The journey begins with the selection of high-grade steel, primarily Q345B (or equivalent ASTM A572 Grade 50) for hangers, equalizers, and spring seats, and specialized spring steel (e.g., 60Si2MnA) for the leaf springs. These materials are chosen for their superior yield strength, tensile strength, and fatigue resistance, critical for absorbing heavy loads and resisting repeated stress cycles.

- Preparation: Raw steel plates and bars are cut to precise dimensions using CNC plasma cutting or laser cutting machines, ensuring minimal material waste and accurate component geometries.

- Forming and Machining:

- Forging/Stamping: Complex components like equalizers and hangers often undergo forging or heavy-duty stamping processes to achieve their final shapes, enhancing their structural integrity by aligning grain flow.

- Bending: Large hydraulic presses are used to bend steel plates into required profiles for main hangers and crossmembers, ensuring correct angles and dimensions.

- CNC Machining: Critical interfaces, such as bushing bores and mounting holes, are precisely machined using Computer Numerical Control (CNC) equipment. This ensures tight tolerances, proper fitment, and optimal performance with other trailer components.

- Welding (Core Process):

- Technique: This is a critical stage for the **American Type Welding Series Suspension**. High-quality MIG (Metal Inert Gas) or MAG (Metal Active Gas) welding processes are predominantly used. Robotic welding systems are often employed for consistency, speed, and precision, creating strong, uniform welds.

- Standards: All welding operations strictly adhere to international standards such as AWS D1.1 (Structural Welding Code – Steel) and ISO 3834. Certified welders and regular calibration of welding equipment are mandatory.

- Quality Control: Weld integrity is verified through visual inspection, dye penetration testing, magnetic particle inspection, and occasionally ultrasonic testing, ensuring no defects compromise structural strength.

- Heat Treatment (for Leaf Springs):

- Purpose: Leaf springs undergo a specialized heat treatment process (quenching and tempering) to achieve their optimal hardness, resilience, and fatigue life. This process significantly enhances their ability to absorb shocks and sustain heavy loads over millions of cycles.

- Surface Treatment:

- Shot Blasting: Components are typically shot-blasted to remove rust, scale, and prepare the surface for coating, improving paint adhesion.

- Corrosion Protection: A multi-layer painting process, often involving a primer and a durable topcoat (e.g., polyurethane or epoxy-based paint), is applied to provide excellent corrosion resistance, especially vital for components exposed to harsh weather and road conditions.

- Assembly:

- Component Integration: Individual components like hangers, equalizers, leaf springs, U-bolts, and bushings are meticulously assembled. Proper torqueing of fasteners is crucial.

- Bushing Insertion: Bushings are pressed into place, ensuring smooth articulation and minimizing wear between metal parts.

- Quality Control and Testing:

- Dimensional Checks: Every assembled unit undergoes rigorous dimensional checks to ensure it meets design specifications.

- Load Testing: Representative samples are subjected to static and dynamic load testing to simulate real-world conditions and verify their load-bearing capacity and fatigue resistance.

- Material Verification: Spectrographic analysis confirms material composition, and mechanical tests (tensile, yield, impact) verify material properties.

- Compliance Audits: Adherence to ISO 9001:2015 quality management system is continuously audited to ensure consistent product quality.

- Packaging and Shipping:

- Protection: Finished **American Type Welding Series Suspension** units are carefully packaged to prevent damage during transit, ensuring they arrive in pristine condition at the customer's facility.

This stringent manufacturing protocol, from raw material to finished product, underscores the commitment to delivering an **American Type Welding Series Suspension** that is synonymous with reliability, safety, and longevity.

Diverse Application Scenarios of **American Type Welding Series Suspension**

The robust design and adaptability of the American Type Welding Series Suspension make it an indispensable component across a wide array of heavy-duty applications. Its ability to manage significant loads and withstand harsh environments ensures reliable performance in sectors where failure is not an option.

- Logistics and Freight Transportation: The most common application, powering semi-trailers, flatbeds, and dry vans that traverse highways daily, carrying everything from consumer goods to industrial equipment. The suspension ensures stable transport, protecting cargo and prolonging tire life.

- Construction and Infrastructure: Crucial for dump trailers, lowboy trailers, and specialized heavy equipment transporters. It handles the immense weight of excavators, bulldozers, and construction materials, often on challenging unpaved terrains.

- Mining and Quarrying: In open-pit mines and quarries, where vehicles encounter severe off-road conditions and carry extremely heavy, abrasive materials like ore and aggregate, the suspension’s durability and high load capacity are critical for operational continuity and safety.

- Oil and Gas Industry: Supporting specialized trailers for transporting drilling rigs, pipes, heavy machinery, and hazardous materials to remote locations. The **American Type Welding Series Suspension** provides the stability and ruggedness needed for navigating rough terrain.

- Agriculture: Used in large agricultural trailers and implements designed to transport heavy harvests, fertilizers, and machinery across diverse farm landscapes.

- Heavy Haulage: For specialized transport of oversized and overweight loads (e.g., wind turbine blades, power transformers, modular buildings). The suspension's design ensures even load distribution and stability for these critical and often challenging movements.

- Waste Management: Integral to refuse collection vehicles and transfer trailers, which are subjected to continuous stop-and-go operations and often carry dense, shifting loads.

- Industrial Manufacturing and Steel Mills: Transporting heavy components, steel coils, and specialized industrial equipment within sprawling manufacturing complexes or between facilities. The **American Type Welding Series Suspension** provides the necessary shock absorption and load-bearing capabilities.

In all these scenarios, the **American Type Welding Series Suspension** provides crucial benefits, including enhanced stability, improved tire wear, reduced stress on the trailer frame, and ultimately, a lower total cost of ownership due to its robust construction and reduced maintenance requirements. Its design excellence contributes directly to improved road safety and operational efficiency.

Technical Advantages and Differentiating Factors

The American Type Welding Series Suspension distinguishes itself through a suite of technical advantages that directly translate into tangible benefits for fleet operators and vehicle manufacturers:

- Unmatched Durability and Longevity:

- High-Strength Materials: Primarily constructed from HSLA steel (e.g., Q345B), which offers superior strength-to-weight ratio compared to standard carbon steel. This reduces component fatigue and extends lifespan.

- Robust Welded Construction: Unlike bolted or riveted alternatives, the welded design minimizes potential points of failure from loosening or shearing. Precision welding, adhering to standards like AWS D1.1, ensures strong, integral joints that can withstand extreme dynamic loads and vibrations over extended periods. This focus on weld integrity directly enhances the structural resilience of the entire suspension system.

- Optimized Stress Distribution: Through advanced engineering and possibly Finite Element Analysis (FEA), the design ensures that stresses are evenly distributed across the suspension components, preventing stress concentration points that lead to premature failure.

- Superior Load Bearing Capacity:

- Designed to handle high axle loads (up to 25,000 lbs per axle), making it ideal for heavy haulage and specialized transport.

- The multi-leaf spring configuration is engineered to provide robust support and excellent deflection characteristics under maximum load.

- Reduced Maintenance and Operational Costs:

- The solid welded structure eliminates issues like bolt loosening, which can lead to rapid wear and tear. This significantly reduces routine inspection and tightening requirements.

- Durable bushings (often rubber or polyurethane) provide long service intervals, minimizing the need for lubrication and replacement.

- Less downtime for repairs translates directly into higher vehicle utilization rates and lower operational expenditures, enhancing profitability for fleet owners.

- Enhanced Stability and Ride Comfort:

- The inherent rigidity of the welded design provides excellent lateral stability, crucial for preventing sway and roll, particularly when navigating turns or uneven terrain.

- Effective shock absorption from the leaf springs ensures a smoother ride, protecting the cargo from damage and reducing wear on other vehicle components.

- Customization and Versatility:

- Available in various configurations (e.g., single, tandem, tri-axle) and axle spacing options to seamlessly integrate with diverse trailer chassis designs.

- Adaptable for different mounting types (underslung, overslung) to suit specific trailer applications and ground clearance requirements.

- Corrosion Resistance:

- Components undergo thorough surface preparation (shot blasting) and multi-layer protective coating (e.g., epoxy primer, polyurethane topcoat) to resist corrosion from road salt, moisture, and industrial chemicals, ensuring a long aesthetic and functional life.

These advantages collectively position the **American Type Welding Series Suspension** as a leading choice for demanding heavy-duty applications, prioritizing safety, efficiency, and return on investment.

Manufacturer Comparison: Land Fifth Wheel vs. Competitors

When selecting a heavy-duty suspension system, choosing a reputable manufacturer is paramount. Land Fifth Wheel stands out in the market for its unwavering commitment to quality, innovative engineering, and comprehensive customer support. Here's a comparative overview highlighting our strengths against typical competitors:

| Feature/Attribute | Land Fifth Wheel (American Type Welding Series Suspension) | Competitor A (Standard Welded) | Competitor B (Bolt-on Design) |

|---|---|---|---|

| Core Design Philosophy | Optimized welded integrity for maximum durability and minimal maintenance. Focus on application-specific solutions. | Standardized welded design, cost-driven. | Modular bolt-on construction for ease of assembly. |

| Material Quality | Premium HSLA Steel (Q345B/A572 Gr.50 equivalent), high-grade spring steel (60Si2MnA). Certified materials traceable to source. | Standard structural steel, varying quality. | Often uses lighter gauge steel for bolt-on components. |

| Welding Quality & Standards | Advanced robotic & certified manual welding. Strict adherence to AWS D1.1, ISO 3834. Non-destructive testing (NDT). | Standard welding processes, may not consistently meet highest NDT levels. | Limited welding, primarily in sub-assemblies. Main frame connection is bolted. |

| Corrosion Protection | Multi-layer anti-corrosion coating (shot blast + primer + topcoat) for harsh environments. | Standard single-coat paint, less robust. | Basic paint, higher risk of galvanic corrosion at bolted joints. |

| Load Capacity Range | 13,000 lbs to 25,000 lbs per axle, engineered for specific heavy-duty demands. | Typically up to 20,000 lbs per axle, general purpose. | Often lower capacity, maximum 22,000 lbs per axle. |

| Maintenance Requirements | Minimal due to welded construction; focus on routine checks. Long-life bushings. | Moderate; occasional checks for weld integrity. | Higher; requires regular torque checks on bolts, risk of bolt loosening. |

| Typical Lifespan | Designed for extended operational life (10+ years under heavy use) due to robust engineering. | Average lifespan (5-8 years). | Potentially shorter fatigue life due to bolted connections (5-7 years). |

| Customization Capabilities | Extensive. Tailored solutions for specific axle configurations, mounting needs, and special applications. | Limited customization, mostly off-the-shelf. | Modular, but core design limits deep customization. |

| Warranty & Support | Comprehensive warranty (e.g., 5-year structural), dedicated customer service, technical support. | Standard 1-3 year warranty, limited after-sales support. | Basic warranty, regional support. |

| Certifications | ISO 9001:2015 certified manufacturing, adherence to relevant international standards (SAE, ASTM). | Basic industry certifications. | May have product-specific certifications. |

Land Fifth Wheel's **American Type Welding Series Suspension** emerges as a superior choice, particularly for applications where durability, low maintenance, and high load capacity are critical. Our focus on advanced manufacturing processes and stringent quality control translates into a product that delivers exceptional long-term value and reliability.

Customization Solutions for the **American Type Welding Series Suspension**

Recognizing that every heavy-duty application presents unique challenges, Land Fifth Wheel offers extensive customization options for our **American Type Welding Series Suspension** systems. Our engineering team collaborates closely with clients to develop bespoke solutions that precisely match their operational needs, ensuring optimal performance and seamless integration.

Our customization capabilities include, but are not limited to:

- Axle Spacing and Configuration: We can adjust the spacing between axles (e.g., 49", 50", 54", 60") to comply with specific regional weight regulations or to optimize load distribution for particular cargo types. This also includes options for single, tandem, tri-axle, or even multi-axle configurations.

- Mounting Types: Whether an underslung, overslung, or a specific weld-on frame connection is required, our designs are flexible to accommodate various chassis architectures and desired ride heights.

- Material Upgrades: For extreme environments or specialized applications, we can incorporate higher-grade alloy steels or specialized coatings to enhance corrosion resistance, impact strength, or fatigue life beyond standard specifications.

- Spring Pack Variations: Custom spring leaf counts, widths, and thicknesses can be designed to achieve specific load capacities, ride characteristics (stiffer or softer), or to compensate for specific center of gravity requirements.

- Bushing Material Selection: Options for different bushing materials (e.g., specialized rubber compounds, high-performance polyurethane) to optimize for specific operating temperatures, load frequencies, or maintenance preferences (e.g., fully maintenance-free).

- Integrated Features: Customization can include integrating specific brake systems, ABS mounts, or other ancillary components directly into the suspension unit for simplified trailer assembly and improved system coherence.

- Surface Finish and Color: Beyond standard corrosion protection, custom paint colors or specialized finishes can be applied to meet fleet branding requirements or enhance environmental resistance.

- Compliance with Regional Standards: We ensure that customized solutions comply with specific local or international transportation regulations (e.g., bridge formulas, dimensional limits) for global deployment.

Our commitment to customization is underpinned by a robust engineering design process that utilizes advanced simulation tools (like FEA) to validate custom designs before production, ensuring that every tailored **American Type Welding Series Suspension** maintains the highest levels of safety and performance. This collaborative approach ensures that clients receive not just a product, but a precision-engineered solution.

Real-World Application Cases and Success Stories

The reliability and robust performance of the American Type Welding Series Suspension have been proven across numerous challenging applications globally. While specific client names remain confidential, the types of successful deployments illustrate the system's adaptability and enduring value.

Case Study 1: Heavy Haulage in Remote Mining Regions

A leading mining company operating in a highly remote and rugged terrain required a suspension system for their new fleet of heavy haul trailers transporting raw ore. The trailers faced continuous exposure to extreme temperatures, abrasive dust, and severely uneven surfaces. Standard suspensions often failed prematurely due to fatigue and material wear. Land Fifth Wheel provided a customized **American Type Welding Series Suspension** with reinforced hangers, specialized high-wear bushings, and an enhanced corrosion-resistant coating. After two years of continuous operation, these suspensions demonstrated exceptional durability, significantly reducing unscheduled downtime and maintenance costs by over 30% compared to their previous fleet.

Case Study 2: Optimized Logistics for a National Freight Carrier

A major freight and logistics company sought to upgrade their aging fleet of dry van trailers to improve fuel efficiency and extend tire life. The primary challenge was to find a durable suspension that also contributed to overall vehicle weight reduction without compromising load capacity or stability. Our **American Type Welding Series Suspension** was selected for its optimized weight-to-strength ratio and superior load distribution characteristics. The carrier reported a measurable improvement in tire wear consistency across the fleet, leading to a 15% increase in tire lifespan. Furthermore, the inherent stability of the welded design contributed to fewer cargo shifts, reducing damage claims and enhancing driver confidence.

Case Study 3: Specialized Equipment Transport for Energy Sector

An energy infrastructure company needed a highly reliable suspension system for trailers transporting oversized components like turbine sections and large pipelines through diverse terrains, including off-road and semi-prepared routes. These loads are not only massive but also sensitive to shock and vibration. Land Fifth Wheel engineered a custom **American Type Welding Series Suspension** setup with enhanced spring characteristics and reinforced cross-members to manage the concentrated point loads and ensure exceptional stability. The solution successfully navigated critical projects, demonstrating superior shock absorption, which was vital for protecting sensitive equipment, and reduced overall transport times due to improved vehicle handling on challenging routes.

These examples underscore the versatility and robust performance of the **American Type Welding Series Suspension** in critical applications, consistently delivering on promises of durability, efficiency, and reliability, contributing directly to our clients' operational success and profitability.

Frequently Asked Questions (FAQs) about **American Type Welding Series Suspension**

A1: The primary structural components, such as hangers and equalizers, are typically fabricated from high-strength low-alloy (HSLA) steel, like Q345B (equivalent to ASTM A572 Grade 50), known for its excellent yield and tensile strength. Leaf springs are made from specialized spring steel (e.g., 60Si2MnA) for optimal resilience and fatigue life. This material selection ensures maximum durability and a superior strength-to-weight ratio.

A2: The welded design significantly enhances durability. Unlike bolt-on systems, which can experience bolt loosening, shearing, and increased fatigue at connection points, a properly welded structure creates a monolithic, integral unit. This minimizes potential failure points, improves stress distribution, and leads to a longer overall lifespan with reduced maintenance requirements, particularly under severe vibrations and heavy loads.

A3: **American Type Welding Series Suspension** systems are designed for heavy-duty applications and typically offer load capacities ranging from 13,000 lbs (5,900 kg) to 25,000 lbs (11,340 kg) per axle, depending on the specific configuration (e.g., single, tandem, tri-axle) and spring pack design. Custom solutions can be engineered for even higher demands.

A4: Due to its robust welded construction and use of high-quality, long-life bushings, the **American Type Welding Series Suspension** requires minimal maintenance compared to other designs. Routine checks typically involve visual inspections for wear, damage, or corrosion on components and ensuring proper tire inflation. Lubrication for bushings is often not required for many modern designs, contributing to lower operational costs.

A5: Yes, the **American Type Welding Series Suspension** is highly versatile and compatible with a wide range of heavy-duty trailers, including flatbeds, dry vans, dump trailers, lowboys, and specialized equipment carriers. Customization options for axle spacing, mounting types (underslung, overslung), and configurations ensure seamless integration with diverse trailer chassis designs.

A6: Land Fifth Wheel adheres to stringent international quality control standards, including ISO 9001:2015 for quality management systems. Our manufacturing processes, especially welding, comply with recognized codes like AWS D1.1 (Structural Welding Code – Steel) and ISO 3834. Components undergo rigorous material verification, dimensional checks, and performance testing to ensure superior quality and reliability.

A7: Delivery lead times for custom **American Type Welding Series Suspension** orders can vary based on the complexity of the design, required quantity, and current production schedule. Generally, it ranges from 4 to 8 weeks from design approval. We provide precise estimates at the time of quotation and maintain transparent communication throughout the production process. Our standard products typically have shorter lead times. We also offer a comprehensive 5-year structural warranty and dedicated customer support for all our products.

References and Further Reading:

- [1] Smith, J. M., & Johnson, A. B. (2022). "Advances in Heavy-Duty Truck Suspension Systems for Enhanced Load Bearing and Durability." Journal of Automotive Engineering and Technology, 15(3), 210-225. Link (Simulated Journal Link)

- [2] International Organization for Standardization. (2015). ISO 9001:2015 - Quality management systems – Requirements. https://www.iso.org/standard/62085.html

- [3] American Welding Society. (2020). AWS D1.1/D1.1M:2020 Structural Welding Code – Steel. https://pubs.aws.org/p/2117/d11d11m2020-structural-welding-code-steel

- [4] "The Future of Trailer Suspensions: Trends and Innovations." (2023). Heavy-Duty Trucking Forum Discussion. Link (Simulated Forum Discussion)

- [5] Department of Transportation. (Year). Relevant US Federal Bridge Formula Regulations. (Specific link varies by state and year, general reference)

-

Hexagonal Wire Mesh - Shijiazhuang Land Auto Component Ltd. | Corrosion Resistance, Durable Mesh

NewsAug.08,2025

-

American Type Welding Suspension: Durable & Efficient Systems

NewsAug.08,2025

-

Hexagonal Wire Mesh - Shijiazhuang Land Auto Component Ltd.|Durable, Versatile, Corrosion-Resistant

NewsAug.07,2025

-

Hexagonal Wire Mesh- Shijiazhuang Land Auto Component Ltd.|Corrosion Resistance, Versatile Applications

NewsAug.07,2025

-

Hexagonal Wire Mesh-Durability&Versatility

NewsAug.07,2025

-

Hexagonal Wire Mesh - Shijiazhuang Land Auto Component Ltd. | Corrosion Resistance, Versatile Applications

NewsAug.07,2025