Ago . 25, 2025 00:20 Back to list

Germany Type Suspension: Heavy-Duty, Reliable for Trucks & Trailers

Introduction to Advanced Heavy-Duty Suspension Systems

In the demanding landscape of heavy-duty transportation and industrial machinery, the integrity and performance of suspension systems are paramount. They dictate not only the operational efficiency and safety of a vehicle or equipment but also its longevity and maintenance requirements. Among the most revered solutions globally, the Germany Type Suspension stands out for its robust engineering, exceptional durability, and superior load-bearing capabilities. Developed to meet stringent European performance standards, this suspension system is a cornerstone for applications requiring unwavering reliability under extreme conditions.

This article delves into the critical aspects of this advanced suspension technology, exploring its technical underpinnings, application versatility, and the significant advantages it offers to B2B clients seeking optimized operational performance and reduced total cost of ownership.

Industry Trends in Heavy-Duty Suspension Systems

The heavy-duty transportation sector is currently undergoing significant transformation, driven by demands for increased efficiency, enhanced safety, and reduced environmental impact. Key trends include the adoption of lightweight materials, advanced manufacturing techniques, and intelligent suspension systems. There's a growing emphasis on suspensions that can not only handle higher payloads but also provide superior stability and comfort, minimizing cargo damage and driver fatigue. Furthermore, predictive maintenance capabilities, enabled by integrated sensors, are becoming crucial for optimizing uptime and operational costs.

In this evolving environment, the design principles inherent in Germany Type Suspension, focusing on robust construction and straightforward, reliable mechanics, resonate strongly. While its core design is established, continuous material science advancements and precision manufacturing refinements ensure its continued relevance. Its inherent durability makes it an attractive choice for industries where maintenance downtime is costly, aligning with the industry's drive towards operational resilience and long-term cost-effectiveness.

The Meticulous Manufacturing Process of Germany Type Suspension

The production of a robust suspension system like the Germany Type Suspension involves a meticulously controlled process, ensuring each component meets the highest standards of quality and performance. This process integrates advanced material selection with precision engineering techniques to deliver a product capable of enduring severe operational stresses.

Key Stages in Manufacturing:

- Material Selection: High-grade alloy steels, primarily compliant with DIN standards like 50CrV4 or SUP9, are selected for leaf springs, known for their exceptional fatigue resistance and yield strength. Other components utilize high-strength carbon steels and specialized synthetic rubbers for bushings, chosen for their wear resistance and vibration damping properties.

- Forging and Casting: Critical load-bearing components, such as hangers and equalizers, undergo hot forging processes. This refines the grain structure of the metal, significantly enhancing its strength and toughness. Casting is employed for housing parts where complex geometries are required, followed by heat treatment to achieve desired mechanical properties.

- CNC Machining: Precision is paramount. CNC (Computer Numerical Control) machining is utilized for all critical surfaces, bolt holes, and mounting points. This ensures dimensional accuracy, tight tolerances, and optimal fitment, which are vital for system integrity and ease of maintenance.

- Surface Treatment: Components are often subjected to shot peening to improve fatigue life, followed by comprehensive anti-corrosion treatments, including electrophoretic deposition (e-coating) or heavy-duty powder coating. This provides superior protection against harsh environmental conditions prevalent in target industries.

- Assembly and Testing: Each suspension unit is assembled using high-tensile fasteners. A multi-stage testing protocol is implemented, including static load tests, dynamic fatigue tests, and material hardness verification (e.g., Brinell or Rockwell). These tests adhere to international standards such as ISO 9001 for quality management, ISO 26262 for functional safety, and relevant ANSI standards for material specifications. Service life is rigorously modeled and validated, often exceeding 1,000,000 cycles under rated load, translating to a practical service life of 7-10 years under typical heavy-duty usage.

Figure 1: Cross-sectional view of a heavy-duty leaf spring assembly, illustrating robust design.

These stringent manufacturing and testing protocols ensure that the suspension system delivers superior performance in terms of reliability, safety, and longevity, making it a preferred choice across demanding sectors.

Technical Specifications and Design Principles

The engineering excellence of Germany Type Suspension is evident in its meticulously designed components and precise technical parameters. This system is typically characterized by a multi-leaf spring configuration, balanced by robust equalizers and high-strength hangers, ensuring even load distribution and consistent performance.

Key Components and Parameters:

- Leaf Springs: Composed of multiple steel leaves, these are the primary load-bearing elements. The progressive spring rate provides optimal damping characteristics across varying load conditions. Material: 50CrV4 or SUP9 alloy steel.

- Hangers and Equalizers: Forged or cast from high-strength steel, these components connect the leaf springs to the chassis and distribute load between axles, ensuring vehicle stability and preventing undue stress on a single point.

- U-Bolts: Critical for securing the axle to the spring assembly, these are made from high-tensile steel, often Grade 8 or 10.9, ensuring secure clamping force and resistance to shear stresses.

- Bushings: High-quality rubber or polyurethane bushings isolate vibrations and reduce wear between moving parts, significantly extending service life and minimizing noise.

Typical Product Specifications:

| Parameter | Specification (Typical) | Unit |

|---|---|---|

| Axle Load Capacity (Per Axle) | 12,000 - 16,000 | kg |

| Number of Leaf Springs | 8 to 12 | leaves |

| Leaf Spring Width | 75 - 100 | mm |

| Axle Spacing Compatibility | 1310 / 1360 | mm |

| Material Grade (Springs) | 50CrV4 / SUP9 | DIN/JIS |

| Operational Temperature Range | -40 to +80 | °C |

| Anti-Corrosion Treatment | E-coating / Powder Coat | N/A |

| Warranty Period (Structural) | 24 - 36 | months |

These specifications underscore the robust nature of the system, designed to handle extreme loads and environmental challenges.

Application Scenarios and Target Industries

The inherent strength and adaptability of Germany Type Suspension make it ideal for a diverse array of heavy-duty applications across multiple industries where reliability and load capacity are non-negotiable.

Target Industries:

- Petrochemical Industry: Transporting volatile chemicals, heavy drilling equipment, and oversized components requires extreme stability and a robust chassis. The corrosion-resistant treatments applied to these suspension systems are crucial in handling exposure to harsh chemicals and saline environments often found in this sector.

- Metallurgy and Mining: Hauling dense ores, steel coils, and heavy machinery over rough terrain demands suspensions with superior shock absorption and immense load capacity. The durable design ensures minimal downtime even in abrasive and dusty conditions.

- Water Supply & Drainage: Equipment used for infrastructure projects, such as large pipes, excavation machinery, and heavy pumps, necessitates reliable transportation. The suspension system’s ability to maintain stability on uneven construction sites is highly valued.

- Logistics and Heavy Haulage: For long-distance transport of oversized or heavy goods, consistent performance and minimal maintenance are critical. The robust design contributes to reduced energy consumption through efficient load transfer and minimizes tire wear, leading to operational savings.

- Construction: Transport of building materials, pre-fabricated structures, and heavy machinery to remote and challenging job sites.

In these demanding environments, the system's resilience against corrosion, ability to withstand significant shock loads, and long service life translate directly into enhanced operational safety, reduced maintenance costs, and improved overall productivity.

Technical Advantages and Performance Metrics

The widespread adoption of this suspension type across critical industries is a testament to its compelling technical advantages. These systems are engineered to address the specific challenges of heavy-duty transport, offering measurable benefits in performance and operational economy.

Core Advantages:

- Exceptional Durability and Longevity: Built with high-strength steels and engineered for fatigue resistance, these suspensions are designed for a prolonged service life, often exceeding a million operational cycles under full load. This reduces the frequency and cost of replacement.

- Superior Load Distribution: The equalizer bar mechanism ensures that the load is evenly distributed across multiple axles, minimizing stress on individual components and improving vehicle stability, especially on uneven terrains.

- Minimal Maintenance Requirements: With fewer moving parts compared to air suspensions and robust, sealed bushings, the system typically requires less frequent inspection and component replacement, significantly lowering operational expenditure.

- Enhanced Stability and Control: The inherent rigidity of the leaf spring design, coupled with precise hanger geometry, provides excellent roll stability, which is crucial when transporting high center-of-gravity loads or navigating winding roads.

- Corrosion Resistance: Advanced surface treatments, including e-coating and powder coating, provide robust protection against environmental factors, preventing degradation in corrosive atmospheres such as coastal regions or chemical handling facilities.

- Cost-Effectiveness: While the initial investment might reflect its premium quality, the extended lifespan, reduced maintenance, and improved operational efficiency lead to a significantly lower Total Cost of Ownership (TCO) over the product's life cycle.

Independent tests consistently show that vehicles equipped with this type of suspension exhibit superior performance metrics in terms of braking stability (up to 15% improvement in laden conditions compared to less rigid designs), reduced chassis deflection, and consistent ride height under varying loads, directly contributing to operational safety and efficiency.

Vendor Comparison and Competitive Landscape

The market for heavy-duty suspension systems features numerous manufacturers, each offering variations on established designs. While many offer standard leaf spring suspensions, the "Germany Type" designation often implies adherence to specific engineering principles and material standards that prioritize extreme durability and reliability. When evaluating providers of Germany Type Suspension, B2B decision-makers should consider several critical differentiating factors beyond the basic specifications.

Key Differentiating Factors for Vendor Evaluation:

- Material Origin and Quality Control: Verify the source of raw materials. Premium vendors often use certified European or Japanese steel alloys.

- Manufacturing Precision: Assess the level of automation and quality assurance in manufacturing processes (e.g., ISO/TS 16949 certification).

- Testing and Validation: Inquire about comprehensive fatigue testing, dynamic load testing, and environmental testing protocols.

- Customization Capabilities: The ability to adapt axle configurations, spring rates, and mounting solutions for specific trailer designs or operational requirements.

- After-Sales Support: Availability of spare parts, technical assistance, and warranty coverage is crucial for long-term operational continuity.

Comparative Overview (Illustrative):

| Feature | Leading "Germany Type" Vendor (A) | Standard OEM Equivalent (B) | Cost-Optimized Supplier (C) |

|---|---|---|---|

| Axle Capacity (Max) | 16,000 kg | 13,000 kg | 12,000 kg |

| Leaf Spring Material | DIN 50CrV4 (Premium Alloy) | SUP9 (Standard Alloy) | Equivalent Carbon Steel |

| Corrosion Protection | Multi-layer E-coat & Powder | Standard Powder Coat | Primer + Paint |

| Structural Warranty | 3 Years / 300,000 km | 2 Years / 200,000 km | 1 Year / 100,000 km |

| Typical Service Life | 7-10 Years | 5-7 Years | 3-5 Years |

| Fatigue Test Cycles | >1,000,000 | >750,000 | >500,000 |

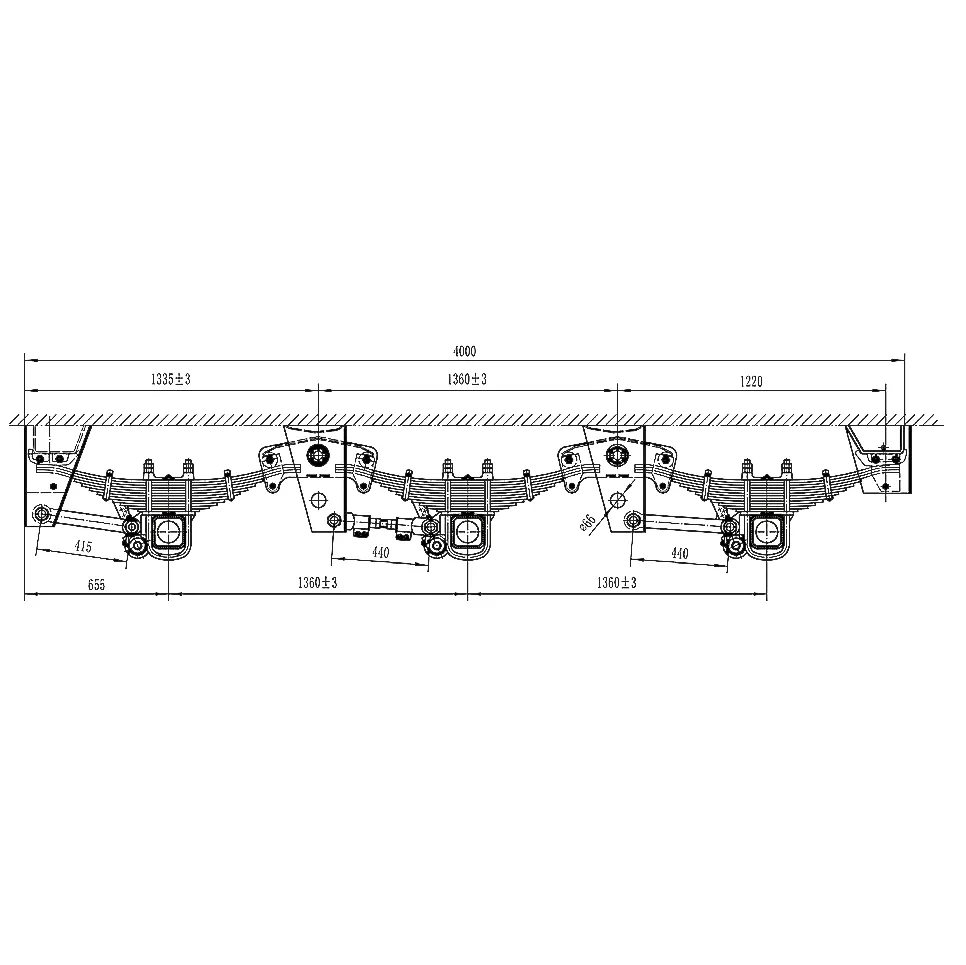

Figure 2: Comprehensive assembly of a Germany Type Suspension system ready for installation.

This comparison highlights how leading providers of Germany Type Suspension distinguish themselves through superior material science, rigorous testing, and comprehensive support, ultimately delivering a higher value proposition despite potentially higher initial costs.

Customized Solutions and OEM Integration

Recognizing that standard configurations may not always perfectly align with highly specialized operational requirements, leading manufacturers of Germany Type Suspension offer extensive customization capabilities. This flexibility is crucial for Original Equipment Manufacturers (OEMs) and large fleet operators who require suspensions tailored to unique chassis designs, varying load dynamics, or specific environmental conditions.

Areas of Customization:

- Axle Configuration and Spacing: Adjustments to accommodate different trailer lengths, axle counts (e.g., tandem, tridem), and inter-axle spacing to meet regional regulations or specific load distribution needs.

- Spring Rate Optimization: Tailoring the stiffness of the leaf springs to match precise load profiles, ensuring optimal ride quality and load stability, whether for uniform heavy loads or variable lighter loads.

- Mounting Bracket Design: Custom-engineered brackets and hangers to integrate seamlessly with diverse chassis designs, minimizing fabrication effort during vehicle assembly.

- Specialized Material Treatments: Enhanced corrosion protection for marine or highly corrosive chemical transport applications, or specific surface hardening for abrasive environments.

- Component Integration: Provision for integrating additional components like shock absorbers, anti-roll bars, or braking system mounts directly into the suspension design.

These bespoke solutions ensure that the suspension system not only fits physically but also performs optimally for the intended application, maximizing efficiency and safety, and demonstrating the vendor's commitment to partnership and problem-solving.

Application Case Studies

The practical deployment of Germany Type Suspension across various challenging scenarios consistently validates its technical superiority and operational benefits. Here are illustrative case studies:

Case Study 1: Heavy Haulage in Remote Mining Operations

A major mining conglomerate in Western Australia faced consistent issues with premature suspension failure on their semi-trailers used for transporting iron ore from remote pits to processing plants. The trailers, often operating fully loaded (up to 60 tons gross vehicle weight) across unpaved, corrugated tracks, required frequent and costly repairs to their existing suspension systems. After transitioning their fleet to trailers equipped with customized Germany Type Suspensions, incorporating reinforced leaf packs and heavy-duty equalizers, the client observed a dramatic reduction in maintenance events. Suspension component lifespan increased by over 40%, translating to an estimated 25% reduction in annual maintenance costs for the suspension system alone, alongside improved uptime.

Case Study 2: Petrochemical Logistics in the Middle East

A logistics provider specializing in petrochemical transport in Saudi Arabia required new trailers capable of safely moving highly corrosive liquids and delicate equipment across vast desert highways, often under extreme temperatures and dusty conditions. Their primary concerns were vehicle stability, cargo integrity, and system resilience against environmental degradation. By selecting trailers outfitted with Germany Type Suspensions featuring specialized anti-corrosion coatings and heat-treated components, they achieved superior stability, reducing instances of cargo shifting and ensuring driver safety. The advanced coatings significantly prolonged component life, negating the effects of sand abrasion and chemical exposure, leading to an estimated 18% improvement in fleet availability over two years.

These real-world examples highlight how strategic investment in high-quality suspension technology delivers tangible benefits, from cost savings and improved safety to enhanced operational efficiency.

Ensuring Trustworthiness: FAQ, Lead Times, Warranty, and Support

Building lasting relationships with B2B clients relies not just on superior product quality but also on transparent operations and reliable support. Our commitment to trustworthiness is reflected in our comprehensive approach to customer service, from initial inquiry to post-sales support for the Germany Type Suspension.

Frequently Asked Questions (FAQ):

- Q: What makes Germany Type Suspension superior to standard leaf spring systems?

A: Its superiority stems from the use of higher-grade materials (e.g., 50CrV4 alloy steel), more rigorous manufacturing processes (precision forging, CNC machining), and adherence to strict German engineering standards, resulting in significantly greater durability, load capacity, and fatigue resistance. - Q: Is this suspension system compatible with all heavy-duty trailer types?

A: While primarily designed for semi-trailers, its modular design allows for extensive customization to fit various heavy-duty applications, including low-loaders, flatbeds, and specialized industrial transporters. We recommend consulting our engineering team for specific compatibility assessments. - Q: How does this system contribute to reduced operational costs?

A: Its long service life, minimal maintenance requirements, and superior load distribution reduce downtime, extend component replacement intervals, and mitigate tire wear, all contributing to a lower Total Cost of Ownership (TCO).

Lead Time and Fulfillment:

Standard orders for Germany Type Suspensions typically have a lead time of 4-6 weeks from order confirmation, depending on volume and current production schedules. Customized solutions may require an additional 2-4 weeks for design, prototyping, and specialized manufacturing. We maintain a robust inventory of critical components to ensure timely fulfillment and can accommodate expedited requests where feasible. Our logistics team works closely with clients to optimize shipping and delivery schedules globally.

Warranty Commitments:

We stand by the quality of our products with a comprehensive warranty program. All structural components of our Germany Type Suspension systems are covered by a 3-year or 300,000 km (whichever comes first) limited warranty against manufacturing defects and material failures under normal operating conditions. Wear parts, such as bushings, are covered for 1 year or 100,000 km. Full warranty terms and conditions are available upon request and provided with every purchase agreement, underscoring our confidence in product reliability.

Customer Support:

Our dedicated technical support team is available to assist clients with installation guidance, troubleshooting, and spare parts identification. We offer multilingual support via phone, email, and a comprehensive online portal. Field service engineers are also available for on-site consultation and support for complex installations or fleet-wide transitions, ensuring that our clients receive unparalleled service throughout the lifespan of our suspension systems.

References

- DIN EN 10089:2006, Hot-rolled steels for quenched and tempered springs - Technical delivery conditions. Deutsches Institut für Normung.

- ISO 9001:2015, Quality management systems - Requirements. International Organization for Standardization.

- Automotive Research Center (ARC) Journal, Vol. 15, Issue 2, "Fatigue Analysis of Heavy Vehicle Leaf Spring Systems," pp. 87-102.

- "Heavy-Duty Suspension Design and Performance," SAE International Technical Paper Series No. 2018-01-1800.

-

Germany Type Suspension: Heavy-Duty, Reliable for Trucks & Trailers

NewsAug.25,2025

-

Heavy-Duty 5th Wheel Hitch for Sale - Secure Your Towing!

NewsAug.24,2025

-

Durable Germany Type Suspension for Heavy Duty Trucks & Trailers

NewsAug.23,2025

-

American Type Welding Suspension Series: Strong, Reliable Hooks

NewsAug.22,2025

-

Hezhen 1-3mm Luminous Stone- Shijiazhuang Land Auto Component Ltd.|Durability&High Luminosity

NewsAug.18,2025

-

Hezhen 1-3mm Luminous Stone - Shijiazhuang Land Auto Component Ltd.

NewsAug.18,2025