Aug . 11, 2025 01:20 Back to list

American Type Welding Series Suspension: Heavy-Duty Ergonomic Support

Introduction to American Type Welding Series Suspension Solutions

In the heavy-duty transportation sector, the integrity and performance of critical components are paramount for operational efficiency and safety. The American Type Welding Series Suspension stands as a cornerstone technology, specifically engineered to meet the rigorous demands of various industrial applications. These suspension systems are vital for trailers, semi-trailers, and specialized heavy vehicles, providing superior load distribution, enhanced stability, and extended component lifespan. Designed to adhere to stringent North American standards, these suspensions are distinguished by their robust welded construction, which offers a higher degree of structural rigidity and durability compared to traditional bolted assemblies. This inherent strength makes them ideal for environments where resilience against dynamic loads and severe operating conditions is a non-negotiable requirement.

The market for heavy-duty suspension systems is continuously evolving, driven by demands for increased payload capacity, improved fuel efficiency, and enhanced driver comfort. Industry trends indicate a growing preference for solutions that not only meet current regulatory standards but also anticipate future requirements for sustainability and operational longevity. American Type Welding Series Suspension systems are at the forefront of this evolution, incorporating advanced materials and precise manufacturing techniques to deliver unparalleled performance. Their applications span across diverse sectors, including logistics, construction, mining, and oil & gas, where reliable and high-performance vehicular components are essential for uninterrupted operations. This article delves into the technical aspects, manufacturing precision, and strategic advantages that position these suspensions as a leading choice for heavy-duty applications worldwide.

Precision Manufacturing Process and Quality Assurance

The manufacturing of American Type Welding Series Suspension components is a complex process demanding meticulous attention to detail and adherence to the highest engineering standards. The journey begins with the selection of premium-grade raw materials, typically high-strength alloy steels renowned for their exceptional tensile strength and fatigue resistance. These materials are carefully chosen to ensure the final product can withstand extreme stresses and dynamic loads encountered in heavy-duty applications. Key manufacturing processes include precision cutting, advanced forming, and robotic welding, which guarantees consistent weld quality and structural integrity across all components.

Post-welding, each suspension undergoes a rigorous series of quality control checks. This includes non-destructive testing (NDT) methods such as ultrasonic testing and magnetic particle inspection to detect any internal flaws or surface discontinuities that could compromise performance. Heat treatment processes, such as quenching and tempering, are precisely controlled to optimize the material's microstructure, enhancing hardness, strength, and toughness. Furthermore, dimensional accuracy is verified using advanced CNC measuring machines, ensuring that components meet exact specifications for seamless integration. Adherence to international standards like ISO 9001:2015 for quality management and ANSI/AWS D1.1 for structural welding codes is non-negotiable, ensuring every American Type Welding Series Suspension unit delivers consistent, reliable performance with an exceptional service life, often exceeding 1 million cycles under typical load conditions.

Key Manufacturing Process Highlights:

- Material Sourcing: High-grade SAE/ASTM specified alloy steels (e.g., ASTM A572 Grade 50) for critical structural components, ensuring superior strength-to-weight ratio and corrosion resistance.

- Precision Machining: CNC milling and turning for critical interfaces, guaranteeing tight tolerances and optimal fitment for bushings, axles, and other connecting parts.

- Robotic Welding: Automated welding ensures consistent, high-penetration welds, minimizing human error and maximizing structural integrity. Welding procedures conform to AWS D1.1 standards.

- Surface Treatment: Shot blasting and corrosion-resistant coatings (e.g., electrophoretic deposition or powder coating) applied to withstand harsh environmental conditions, extending the product's lifespan significantly, particularly in corrosive environments like those found in petrochemical or marine applications.

- Fatigue Life Testing: Samples are subjected to accelerated life cycle testing in accordance with SAE J2040 and ECE R90 standards, simulating years of operational stress to validate design and material choices.

Technical Specifications and Performance Advantages

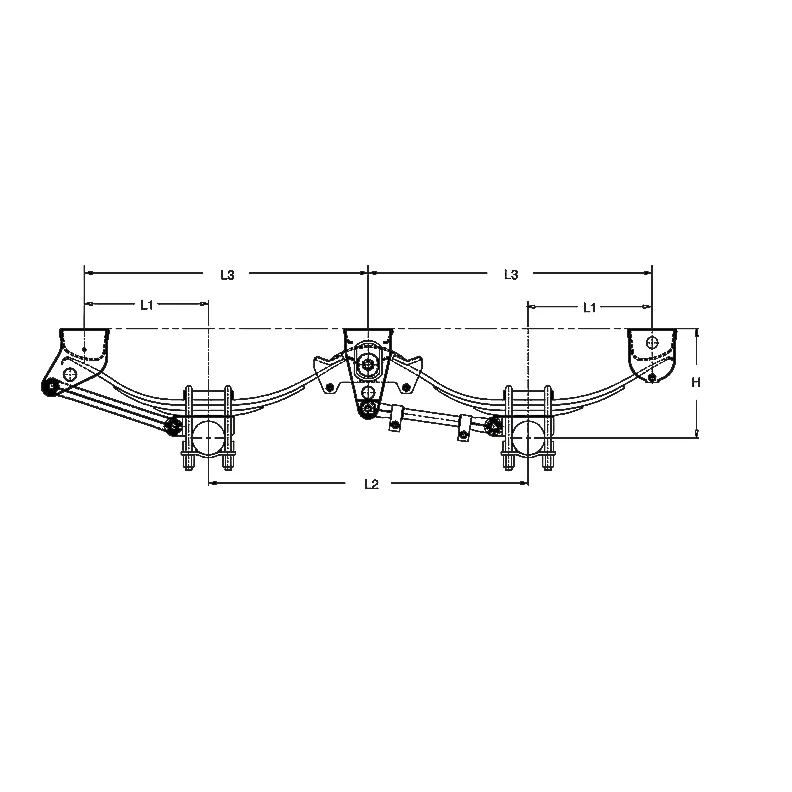

The superior performance of American Type Welding Series Suspension systems is rooted in their meticulously engineered technical parameters. These systems are designed to offer optimal load-carrying capacity, superior articulation, and exceptional stability, even under the most demanding conditions. Critical design elements include robust spring seats, durable equalizers, and high-quality leaf springs, all working in concert to provide a balanced and resilient suspension. The welded design, as opposed to bolted, eliminates potential weak points from loosening over time due to vibration and stress, thereby enhancing long-term reliability and reducing maintenance requirements.

Typical American Type Welding Series Suspension Parameters:

| Parameter | Specification Range | Benefits/Notes |

|---|---|---|

| Axle Load Capacity | 25,000 lbs - 30,000 lbs per axle | Optimized for heavy-duty commercial transport and specialized industrial equipment. |

| Spring Type | Multi-leaf or Parabolic Leaf Spring | Enhanced ride comfort, reduced road shock, and superior load support. |

| Spring Width | 3.5" (90mm) to 4.0" (100mm) | Standardized for broad compatibility and robust support. |

| Hanger Spacing | Varies by model (e.g., 49", 54", 60") | Configurable for various trailer lengths and axle configurations. |

| Material Grade | High-strength low-alloy steel (e.g., ASTM A572 Gr. 50) | Provides exceptional yield strength and ductility for demanding environments. |

| Corrosion Resistance | Standard or Enhanced Coating Options | Extended lifespan in harsh operating conditions, reducing total cost of ownership. |

The technical advantages of American Type Welding Series Suspension are multifaceted. Their robust construction translates into superior fatigue life and reduced downtime, critical factors for B2B operations. Furthermore, the precise engineering ensures optimal tire wear uniformity, contributing to significant operational savings through extended tire life and improved fuel efficiency. The inherent stability of these welded suspensions also enhances vehicle handling and safety, particularly when navigating challenging terrains or transporting highly sensitive cargo. Their design minimizes vibration transmission to the trailer frame, protecting both the cargo and the structural integrity of the vehicle over its operational lifespan.

Diverse Application Scenarios and Client Experience

The versatility of American Type Welding Series Suspension systems allows their deployment across a wide spectrum of heavy-duty industries. In the construction sector, they are integral to dump trailers and lowboy haulers, supporting the transport of heavy machinery and aggregates over rough terrain. Their durability ensures continuous operation, minimizing costly delays. For the petrochemical industry, these suspensions are crucial for tank trailers carrying hazardous materials, where safety and stability are paramount. The anti-corrosion treatments applied during manufacturing ensure longevity even when exposed to harsh chemicals and challenging climatic conditions.

In the logistics and freight transport industry, particularly for long-haul operations, the stability and load-bearing capacity of American Type Welding Series Suspension systems contribute to reduced cargo damage and optimized delivery schedules. Our clients consistently report enhanced vehicle uptime and reduced maintenance overheads after integrating these suspension solutions. For example, a major North American trucking fleet operating over 500 trailers reported a 15% reduction in suspension-related repairs and a 5% improvement in fuel economy after switching to our American Type Welding Series Suspension products across their fleet over a two-year period. This directly translates into significant operational savings and improved profitability.

Furthermore, in niche markets like mining and waste management, where vehicles encounter extreme dynamic loads and highly abrasive environments, the ruggedness and reliability of these suspensions prove invaluable. Their robust design minimizes the impact of constant vibrations and shocks, prolonging the life of not only the suspension itself but also associated components like tires and chassis, leading to lower total cost of ownership. The ability to handle diverse loads, from bulk materials to specialized equipment, underscores their versatility and strategic importance for businesses seeking dependable heavy-duty transport solutions.

Customization and Manufacturer Comparison

While standard American Type Welding Series Suspension models cater to a broad range of applications, specific operational requirements often necessitate customized solutions. Leading manufacturers offer extensive customization options, including variations in axle spacing, spring rates, ride heights, and specific material grades for extreme environments. This flexibility ensures that businesses can acquire suspension systems perfectly tailored to their unique fleet configurations and operational challenges. Customization can involve finite element analysis (FEA) to simulate performance under specific load cases, optimizing the design before manufacturing begins.

When comparing manufacturers of American Type Welding Series Suspension systems, several key factors distinguish superior providers. Beyond raw technical specifications, it is crucial to evaluate a manufacturer's commitment to quality assurance, their engineering capabilities, and their post-sales support infrastructure. A reputable manufacturer will possess certifications like ISO 9001:2015, demonstrate robust internal testing protocols, and have a long-standing track record of delivering reliable products. Furthermore, their ability to offer comprehensive technical support, spare parts availability, and responsive customer service is vital for minimizing potential operational disruptions for their B2B clients. Companies with decades of industry leadership, proven partnerships with major OEMs, and strong global distribution networks often represent the most authoritative choices.

Manufacturer Comparison Factors:

- Certifications: Verify ISO 9001:2015, IATF 16949 (for automotive sector), and specific welding certifications (e.g., AWS D1.1).

- R&D Investment: Manufacturers investing in advanced metallurgy, simulation software, and new product development tend to offer cutting-edge solutions.

- Warranty & Support: Comprehensive warranty policies and accessible technical support indicate confidence in product quality and commitment to customer success.

- Global Reach & Logistics: A strong distribution network ensures timely delivery and parts availability, reducing lead times and downtime.

Trustworthiness: FAQ, Delivery & Warranty

Frequently Asked Questions (FAQ)

- Q1: What is the typical lifespan of an American Type Welding Series Suspension?

A1: With proper maintenance and under normal operating conditions, these suspensions are engineered for a service life exceeding 1 million cycles, often translating to 10-15 years or more in typical heavy-duty usage.

- Q2: Are these suspensions compatible with various axle brands?

A2: Yes, American Type Welding Series Suspension systems are designed for broad compatibility with leading American and international axle manufacturers, ensuring seamless integration into existing fleet configurations. Specific compatibility can be confirmed with technical drawings.

- Q3: What maintenance is required for these suspensions?

A3: While inherently robust, routine checks for wear on bushings, spring integrity, and proper torque of U-bolts are recommended. The welded design significantly reduces maintenance associated with loose bolts common in other suspension types.

Delivery & Lead Times

Understanding the critical nature of delivery timelines in B2B operations, we maintain transparent and efficient logistics. Standard American Type Welding Series Suspension orders typically have a lead time of 4-6 weeks from order confirmation, subject to current stock and production schedules. For customized solutions or bulk orders, a detailed production and delivery schedule is provided upon technical specification finalization, ensuring accurate planning for our clients. Our robust supply chain management and strategic partnerships allow for reliable and on-time delivery globally, minimizing disruption to your operations.

Comprehensive Warranty and Customer Support

We stand behind the quality and durability of our American Type Welding Series Suspension products with a comprehensive warranty. Our standard warranty covers material defects and manufacturing faults for a period of 5 years or 500,000 miles, whichever comes first, underscoring our confidence in our engineering and manufacturing processes. Our dedicated customer support team is available to assist with technical inquiries, installation guidance, and any post-sales support needs, ensuring that your investment delivers long-term value and performance. We believe that exceptional product quality must be matched by equally exceptional service.

Conclusion and Industry Leadership

The American Type Welding Series Suspension represents a pinnacle of engineering excellence in heavy-duty trailer components. Its robust design, precision manufacturing, and adherence to rigorous quality standards ensure unparalleled reliability, extended service life, and superior operational performance. From diverse application scenarios in construction and logistics to specialized uses in petrochemical and mining industries, these suspension systems consistently deliver the durability and stability required for the most demanding tasks. Investing in such advanced suspension technology translates directly into reduced maintenance costs, improved fuel efficiency, enhanced safety, and ultimately, a lower total cost of ownership for fleet operators and manufacturers. As the industry continues to advance, the demand for resilient, high-performance solutions like the American Type Welding Series Suspension will only grow, solidifying its position as an indispensable component for the future of heavy transport.

Authoritative References:

- ISO 9001:2015 - Quality management systems — Requirements. International Organization for Standardization.

- ANSI/AWS D1.1/D1.1M:2020 - Structural Welding Code – Steel. American Welding Society.

- SAE J2040: Heavy Truck/Trailer Trailer Axle and Suspension System Test Procedure. SAE International.

- ECE Regulation No. 90 - Uniform provisions concerning the approval of replacement brake lining assemblies for power-driven vehicles and their trailers. United Nations Economic Commission for Europe.

-

American Type Welding Series Suspension: Heavy-Duty Ergonomic Support

NewsAug.11,2025

-

Hexagonal Wire Mesh - Shijiazhuang Land Auto Component Ltd.|Versatile Solutions,Durable Corrosion Resistance

NewsAug.11,2025

-

Robust Germany Type Suspension for Commercial Vehicles & Trailers

NewsAug.11,2025

-

Hexagonal Wire Mesh - Shijiazhuang Land Auto Component Ltd.|Corrosion Resistance, Durable & Versatile

NewsAug.10,2025

-

Hexagonal Wire Mesh - Shijiazhuang Land Auto Component Ltd. | Durable, Corrosion-Resistant, Versatile

NewsAug.10,2025

-

Hexagonal Wire Mesh-Shijiazhuang Land Auto Component Ltd.|Corrosion Resistance, Customization

NewsAug.10,2025