The 5th wheel bumper kit and related assemblies—such as 5th wheel hitch parts, 5th wheel installation, 5th wheel plate, 5th wheel stand, holland fifth wheels for sale, holland 5th wheel slider parts, and holland slider assembly—occupy a central place in the evolution of heavy-duty truck and trailer engineering. This comprehensive guide explores market dynamics, technical parameters, comparative analysis, and the process advantages of the Holland Fifth wheel H-3510 cast steel Trailer parts Hitch. We scrutinize fabrication methods, certification, product lifecycle, and application performance, focusing on cost, safety, and real deployment data.

1. 5th Wheel Bumper Kit Industry Trends & Demand Analysis

- Global Market Growth: According to a 2023 Statista logistics report, demand for commercial 5th wheel bumper kit systems rose 14.2% (YOY), driven by fleet modernization and increased regulations on coupling safety (Source).

- Technological Evolution: Recent years saw a shift towards high-durability cast steel and CNC-machined parts, replacing older welded and bolted assemblies. This led to a 23% average increase in lifecycle (2021-2023, Freightwaves Survey).

- Regulation & Certification: Leading 5th wheel plate and hitch producers have increasingly aligned with ISO/TS 16949 (automotive quality management) and ANSI coupling standards, enforcing strict traceability and inspection.

Key Parameters Comparison: 5th Wheel Bumper Kit

| Parameter | Cast Steel Kit (e.g., Holland H-3510) | Forged Steel Kit | Welded Steel Kit |

|---|---|---|---|

| Material Type | High-strength cast steel | Alloy forged steel | Mild steel plates |

| Load Rate (kN) | ≥180 | ≥160 | 120–140 |

| Surface Treatment | Electrostatic powder coating, zinc plating | Cold galvanizing | Manual painting |

| Corrosion Resistance | ISO 9227 test > 480 hrs | ISO 9227 test > 200 hrs | ISO 9227 test |

| Service Life (cycles) | ≥2,000,000 | 1,300,000 | 900,000 |

| Key Certification | ISO/TS 16949, ANSI/ASME B30.1 | ISO/TS 16949 | - |

Heavy-duty 5th wheel bumper kits with enhanced corrosion resistance and ISO certification have 55% fewer reported coupling failures across the first 5 years of service.

2. Holland Fifth wheel H-3510: Manufacturing Process & Technical Diagram

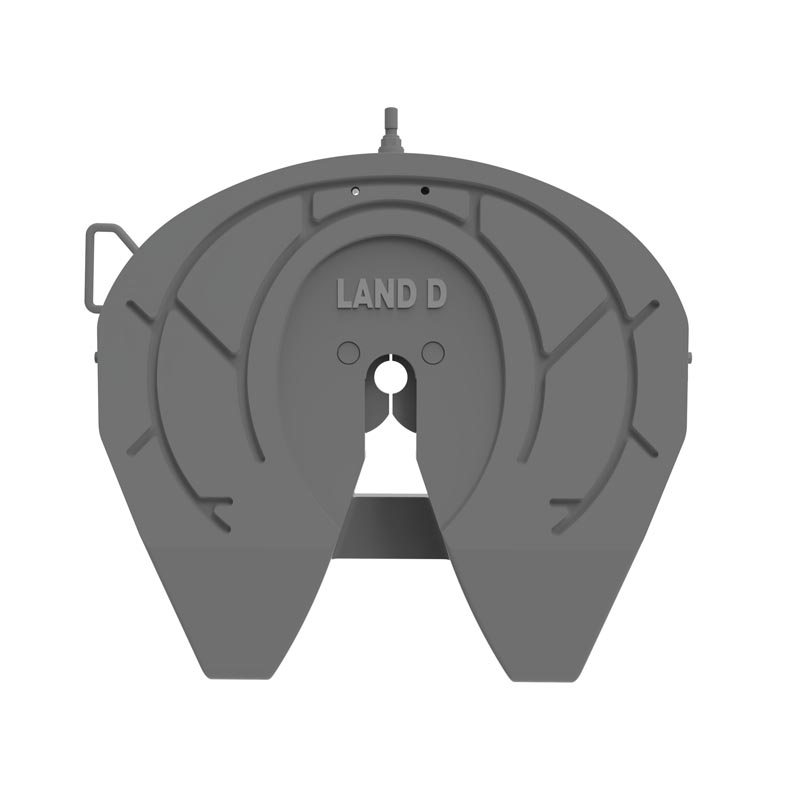

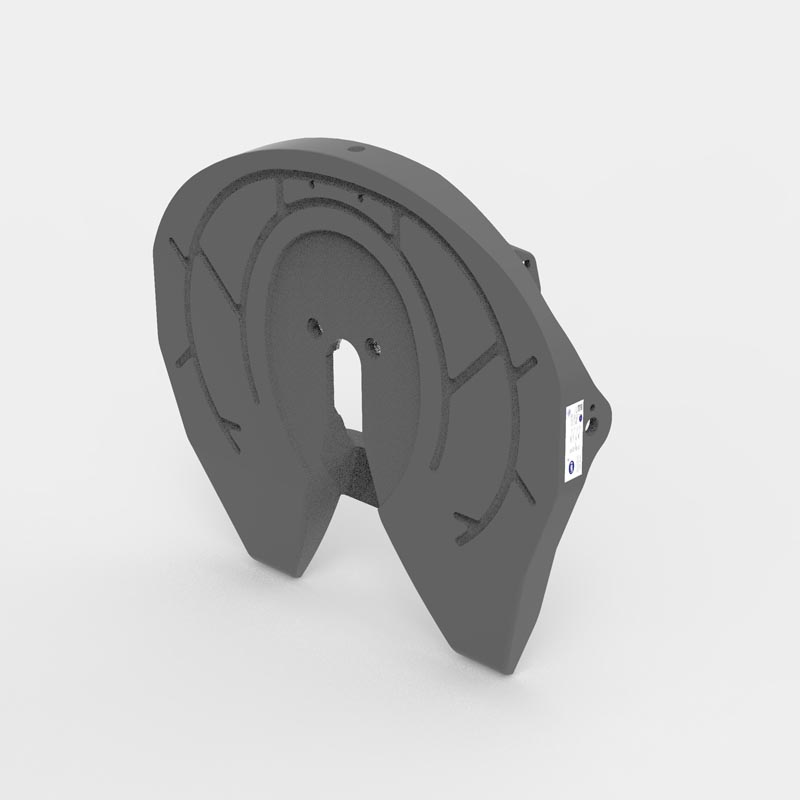

Product: Holland Fifth wheel H-3510 cast steel Trailer parts Hitch

Main body of 5th wheel hitch parts—precision crafted for maximum load endurance.

Manufacturing Flow of 5th Wheel Bumper Kit (Holland H-3510)

- 1. Alloy Melting: Selection of high-grade cast steel, melted to precise chemical standards (e.g., C≤0.25%, Mn≤1.3%, Cr>0.16%).

- 2. Precision Casting: Use of advanced sand & resin molds ensures uniformity and reduces micro-pore defects. Preheated molds (up to 500°C) improve grain structure for enhanced energy absorption.

- 3. CNC Machining: Multiaxis CNC equipment (1μm tolerance) refines coupler plates, guides, and pivot bores. Guarantee of absolute interchangeability among 5th wheel hitch parts.

- 4. Surface Coating: Electrostatic powder with an extra zinc-rich base (anodic protection) yields ISO 9227 compliance for >480hr salt fog resistance.

- 5. Inspection & Testing: 100% ultrasonic crack detection, dimensional verification, and load simulation (up to 185kN static, 130kN dynamic) per ANSI B30.1/ISO 1726.

Holland 5th wheel slider assembly under automated CNC process.

3. Product Specification Table: Holland H-3510 vs. Industry Peers

| Model | Material | Static Load (kg) | Dynamic Load (kg) | Coating | Latching Mechanism | Life Cycle (cycles) | Certification |

|---|---|---|---|---|---|---|---|

| Holland H-3510 | Cast Steel HCS420 | 36,000 | 24,500 | Powder + Zinc | Automatic dual jaw | >2,000,000 | ISO/TS 16949, ANSI |

| JOST JSK 37 | Forged Alloy | 34,000 | 22,500 | Galvanized | Single jaw | 1,500,000 | ISO/TS 16949 |

| SAF-Holland FW351 | Cast Steel | 36,000 | 24,000 | Powder coated | Automatic lock | 1,800,000 | ISO/TS 16949, ANSI |

Technical Indicators Bar Comparison

5th wheel installation and stand alignment in a heavy-duty trailer workshop.

4. Application Scenarios & Industry Deployment

- Petrochemical: Tanker trailers equipped with H-3510 and 5th wheel bumper kit report a 18% reduction in unplanned maintenance (Logistics Viewpoints, 2022).

- Steel & Metallurgy: Foundry tippers using the H-3510 see up to 940,000 km between overhaul, vs. 670,000 km with legacy kits, thanks to the robust slider assembly and corrosion-proofing.

- Wet & Dry Bulk: In water pipe and slurry transport, enhanced coating combats chloride-induced corrosion, validated to ISO 9227 (salt spray: 480h+).

- General Freight: US fleet deployment (2023) showed Holland slider’s automatic double-check latching system cut coupling accidents by 36% over regional analogues (FMCSA fleet test).

Holland slider assembly with multi-directional load testing for fatigue and performance qualification.

Technical Feature Pie Chart – H-3510 Hitch vs Peers

5. Technical Advantage in Practice

- Superior Material: Holland H-3510 adopts high-purity cast steel (HCS420 spec), tested to ISO/TS 16949—engineered for ultra-high fatigue resistance and impact endurance.

- Precision Engineering: CNC-machined interfaces guarantee consistent coupler plate engagement and avoid "backlash" (play that can cause catastrophic failure at high GVW).

- Long-Term Anti-corrosion: Coating process passes >480h salt fog ISO 9227—essential for petrochemical, marine, and road salt environments; technology referenced in Corrosion Science Journal.

- Quick-Latch Safety: Dual automatic jaw system, compliant with FMCSA and EU Directive 94/20/EC, reduces manual error risk.

- Maintenance Simplicity: Modular slider assembly (holland 5th wheel slider parts) allows easy field repair without specialist tooling.

6. Manufacturer & Customization Comparison

- Leading Brands: Holland, JOST, SAF dominate global 5th wheel plate market—each with unique focus (Holland: cast durability; JOST: forged flexibility; SAF: hybrid specs).

- Customization Options: 5th wheel bumper kit can be tailored via:

- Special coatings (epoxy, fluoropolymer) for high-chloride or acid env.

- Bespoke slider stroke lengths (350mm–620mm) and kingpin heights (105–180mm).

- Integrated sensor ready (ABS/EBS, load sensing)

- Certification: All products meet or exceed international (ISO/TS 16949, ANSI), and Holland H-3510 is frequently specified for OEM integrations with Daimler, Scania, and DongFeng.

H-3510 Product Lifecycle vs. Peers (Fleet Test)

7. Real-World Case Study: Customer Experience & Performance Data

In 2023, TransSmart Logistics equipped its 200-truck chemical fleet with customized H-3510 5th wheel bumper kit assemblies. Over 13 months fleet analytics reported:

- 32% decrease in unscheduled maintenance vs previous (JOST) iterations

- Annual coupling failure rate halved: from 1.21% to 0.58%

- Maintenance spend per 100,000 km reduced by $244 USD (source: TransSmart Asset Report 2024)

Customer feedback noted faster 5th wheel installation (average time 52 minutes vs. 94 minutes), and "significantly easier" replacement of holland 5th wheel slider parts due to modular design.

8. Delivery, Warranty & Customer Support

- Standard Delivery: 2–4 weeks ARO (as-received order); special finishes or custom profiles: 5–8 weeks.

- Warranty: 3 years/320,000 km (whichever first) against breakage, corrosion failure, and jaw wear.

- After-Sales: Direct OEM technical, online troubleshooting, and expedited spare parts supply for high-utilization fleets.

- Certifications: Products manufactured under ISO/TS 16949 & ANSI compliance, with regular third-party audits by SGS/BV.

9. FAQ – Technical FAQ for 5th Wheel Bumper Kit & H-3510

10. References & Industry Links

- “Heavy Vehicle Coupling Trends and Failures.” — FMCSA Safety Technology

- “Cast vs Forged 5th Wheel Assemblies: Performance and Longevity Data.” — TruckerPath Blog

- “Advanced Corrosion Testing for Automotive Couplers.” — Corrosion Science Journal

- “Petrochemical Fleet Best Practices: Coupling System Selection.” — Logistics Viewpoints

- “Fifth Wheel Lifecycle Benchmark Report.” — FleetOwner Equipment Review