Сер . 11, 2025 00:40 Back to list

Robust Germany Type Suspension for Commercial Vehicles & Trailers

Understanding the Evolution and Significance of Germany Type Suspension in Modern Heavy-Duty Applications

The landscape of heavy-duty transportation and industrial machinery has consistently evolved, driven by the incessant demand for greater efficiency, enhanced safety, and superior durability. Central to this evolution is the design and implementation of advanced suspension systems. Among the myriad of available options, the Germany Type Suspension has emerged as a cornerstone technology, particularly renowned for its robust construction, meticulously engineered parameters, and unparalleled reliability in the most demanding operational environments. This suspension system, characterized by its distinct design philosophy and emphasis on performance longevity, represents a significant leap from conventional leaf spring or air suspension configurations in certain specialized sectors. Its adoption is not merely a preference but often a necessity for applications requiring a fine balance between payload capacity, dynamic stability, and reduced maintenance cycles. The design principles embedded within this type of suspension draw heavily from rigorous German engineering standards, focusing on precision, material integrity, and comprehensive performance validation. As industries globally navigate increasingly complex logistical challenges and strive for higher operational uptime, the role of a dependable suspension system like the Germany Type Suspension becomes ever more critical, influencing everything from fuel efficiency to tire wear and driver comfort. This comprehensive exploration delves into its intricate details, from manufacturing to application, highlighting why it stands as a preferred solution for discerning B2B stakeholders.

The increasing global trade and the expansion of infrastructure projects have amplified the need for transportation solutions capable of handling heavier loads over diverse terrains with unwavering stability. This trend directly underpins the growing market demand for sophisticated suspension systems that can mitigate the stresses of continuous heavy hauling. While air suspension offers superior ride comfort and adjustable height, and traditional leaf spring systems offer simplicity and cost-effectiveness, the Germany Type Suspension carves out its niche by providing a unique blend of structural rigidity, high load-bearing capacity, and exceptional durability, often surpassing the lifespan of other types in specific heavy-duty scenarios. This robust design makes it particularly suitable for trailers, semi-trailers, and specialized vehicles operating in sectors such as mining, construction, and heavy industrial logistics, where operational conditions are typically harsh and unforgiving. Furthermore, the commitment to stringent quality control during its manufacturing process ensures that each unit delivers consistent performance, reducing the total cost of ownership over its extensive service life. The adaptability of its design also allows for tailored configurations, addressing specific axle load requirements and vehicle dynamics, making it a versatile choice for original equipment manufacturers (OEMs) and fleet operators alike who prioritize long-term asset performance and safety. This section sets the stage for a deeper dive into its technical specifications, manufacturing precision, and diverse application profiles, establishing its undisputed relevance in modern heavy-duty transport.

Technical Parameters and Core Specifications of Germany Type Suspension Systems

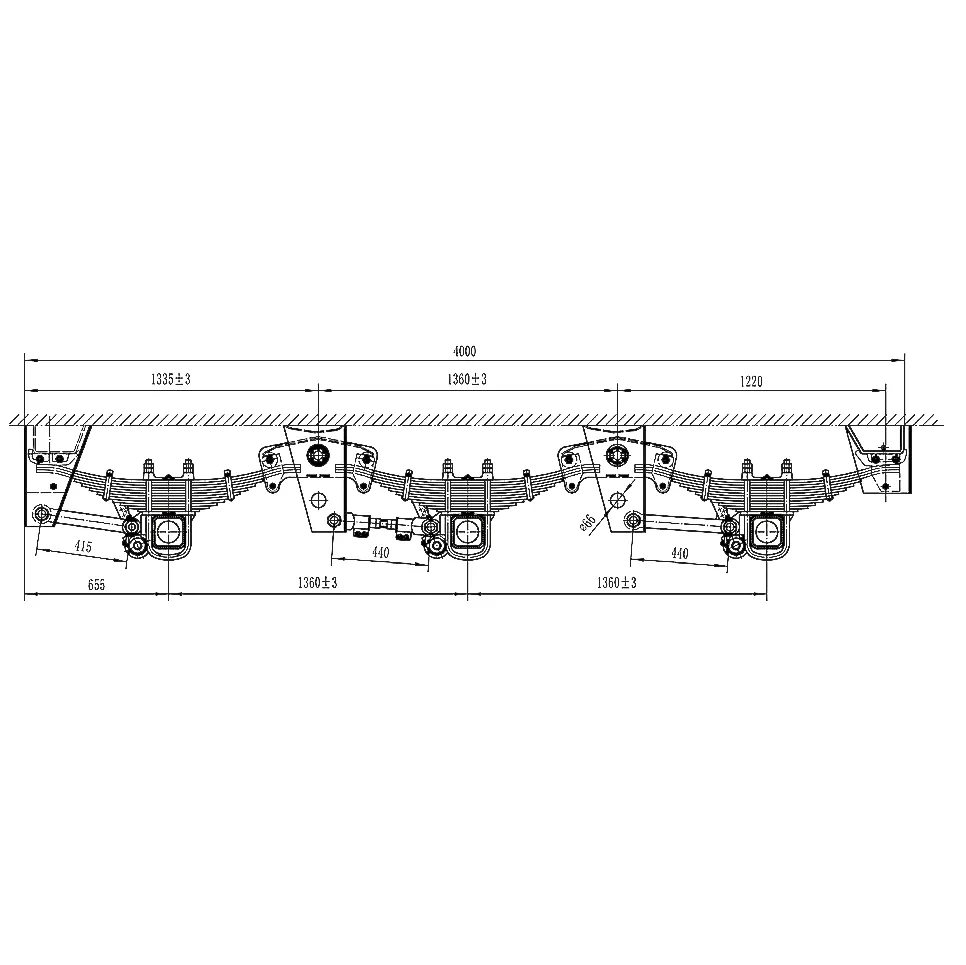

The efficacy of any suspension system is fundamentally defined by its technical parameters, and the Germany Type Suspension excels in this regard through a meticulously engineered design that prioritizes strength, stability, and longevity. A key characteristic is its high axle load capacity, typically ranging from 12,000 kg to 16,000 kg per axle, allowing for the transport of substantial payloads with structural integrity. This robust capacity is achieved through the strategic use of high-strength alloy steels, often featuring materials like 60Si2Mn or SUP9, known for their excellent fatigue resistance and yield strength. The suspension's primary components include heavy-duty leaf springs, often multi-leaf configurations for superior load distribution, robust U-bolts, sturdy spring seats, and specialized hangers designed to withstand significant shear and tensile forces. The spring eye bushes, critical for articulation and absorbing road shock, are typically made from high-grade polyurethane or specialized rubber compounds, offering extended wear life and reduced friction compared to traditional metal bushings. Furthermore, the installation parameters, such as the standard track width (e.g., 1840mm) and varying spring lengths (e.g., 1200mm to 1300mm), are optimized for diverse trailer designs, ensuring compatibility and optimal performance across a wide range of heavy-duty vehicles. These precise specifications are not arbitrary; they are the result of extensive research and development, combined with real-world application data, ensuring the system performs reliably under continuous stress and variable road conditions, a critical factor for B2B operators focused on maximizing asset utilization and minimizing downtime.

Beyond basic load capacities, the performance metrics of the Germany Type Suspension are further defined by its damping characteristics and geometric stability. The design often incorporates advanced shock absorbers, meticulously tuned to complement the spring rates, thereby controlling oscillation and enhancing tire-to-road contact, which is crucial for vehicle stability and safety, especially during braking or cornering with heavy loads. The robust construction of the hangers and equalizers ensures proper load transfer between axles in multi-axle configurations, preventing uneven weight distribution that could lead to premature tire wear or structural fatigue. Critical dimensions, such as the mounting height and overall width, are standardized to facilitate interchangeability and ease of integration into existing chassis designs, reducing complexity for manufacturers and repair shops. Precision engineering extends to the bolt patterns and hole sizes, which adhere to strict tolerances, guaranteeing a secure and long-lasting assembly. The system’s design inherently provides a high degree of roll stability, minimizing body roll during turns, a significant advantage for transporting high-center-of-gravity loads. This attention to detail in every parameter underscores its suitability for rigorous applications, ensuring that operators can depend on consistent, predictable performance day in and day out, ultimately contributing to safer operations and extended vehicle lifespan.

Typical Germany Type Suspension Technical Specifications

| Parameter | Specification Range | Key Benefits |

|---|---|---|

| Axle Load Capacity | 12,000 kg - 16,000 kg (per axle) | High payload capability, robust structural integrity. |

| Leaf Spring Material | 60Si2Mn (or SUP9 equivalent) | Superior fatigue resistance, high elasticity. |

| Number of Leaf Springs | 9 to 13 leaves (common) | Optimized load distribution, enhanced damping. |

| Spring Eye Bushing | High-grade Polyurethane / Specialized Rubber | Extended wear life, reduced noise and vibration. |

| Standard Track Width | Approx. 1840 mm | Ensures broad compatibility with heavy-duty axles. |

| Axle Spacing | 1310 mm (common), adjustable | Optimized for load distribution and maneuverability. |

| Suspension Type | Mechanical (Leaf Spring) | High durability, low maintenance, excellent stability. |

| Finish/Coating | Black Paint, Anti-corrosion coating | Enhanced resistance to rust and environmental degradation. |

Precision Manufacturing Process of Germany Type Suspension

The superior performance and extended lifespan of the Germany Type Suspension are direct outcomes of its rigorous and meticulously controlled manufacturing process, adhering to stringent international standards such as ISO 9001 for quality management and often meeting or exceeding ANSI specifications for mechanical components. The journey begins with the selection of high-grade raw materials, primarily specialized alloy steels like 60Si2Mn, renowned for their exceptional strength-to-weight ratio and fatigue resistance. These materials undergo a series of precise processing steps. First, the steel is cut and shaped to exacting dimensions, followed by heat treatment processes such as quenching and tempering. Quenching involves rapid cooling to achieve optimal hardness, while tempering is applied to reduce brittleness and enhance toughness, creating a material that can withstand continuous heavy loads without deformation or fracture. Spring forming, often through hot coiling or pressing for multi-leaf springs, ensures the correct curvature and spring rate. Each leaf spring then undergoes shot peening, a cold working process that introduces compressive residual stress on the surface, significantly improving its resistance to fatigue cracking and extending its service life. This attention to detail in material science and preliminary processing lays the foundational integrity of the suspension system.

Subsequent stages involve the fabrication of associated components such as hangers, equalizers, and U-bolts. These parts are typically manufactured through a combination of casting, forging, and precise CNC machining. Forging enhances the grain structure of the metal, leading to superior mechanical properties and strength, particularly crucial for high-stress components like hangers that bear significant load. CNC machining ensures that critical dimensions, such as bore diameters for bushings and bolt hole patterns, meet exceptionally tight tolerances, vital for proper alignment and fitment during assembly. Welding, where applicable, is executed using advanced techniques, with welds undergoing non-destructive testing (NDT) such as ultrasonic or magnetic particle inspection to detect any internal flaws. Surface treatment is another critical step, often involving phosphating or black painting with anti-corrosion agents, providing excellent resistance against rust, abrasion, and environmental elements, which is paramount for applications in corrosive environments like petrochemical or coastal regions. Before final assembly, all individual components undergo rigorous quality checks, including dimensional inspection, material hardness tests, and crack detection. The assembled suspension units are then subjected to dynamic load testing, fatigue testing, and deflection tests to simulate real-world operational conditions, ensuring they meet specified performance parameters and projected service life. This multi-stage quality assurance process guarantees that each Germany Type Suspension unit delivered offers peak performance and reliability.

The typical service life of a well-maintained Germany Type Suspension system, given its robust manufacturing process and material quality, can exceed 10 years or millions of kilometers under standard operating conditions. In demanding industries, such as heavy-duty logistics, construction, mining, and specialized transport for oil and gas (petrochemical), metallurgy, and even municipal services like water supply and drainage systems (for heavy equipment transport), its durability proves invaluable. For instance, in the petrochemical industry, where heavy equipment like pressure vessels or heat exchangers need to be transported, the suspension's anti-corrosion properties and high load capacity are crucial. Its design significantly minimizes wear and tear on tires and chassis components, contributing to energy saving by reducing rolling resistance and enhancing overall vehicle efficiency. In metallurgical operations, which involve transporting dense raw materials or finished products, the system's ability to maintain stability under extreme static and dynamic loads prevents structural damage to both the cargo and the vehicle. Moreover, in municipal water and drainage projects, where heavy machinery like excavators or large pipes are moved across varied urban and off-road terrains, the suspension's superior damping and stability ensure safe and efficient transport, even over uneven surfaces, preventing costly delays and maintenance. The stringent testing standards, including ISO 9001 and often internal OEM-specific durability tests, validate its resilience against environmental factors, mechanical stress, and chemical exposure, ensuring reliability for decades.

Key Technical Advantages of Germany Type Suspension Systems

The Germany Type Suspension stands out in the heavy-duty sector due to a combination of inherent design advantages that translate directly into operational benefits for B2B users. Firstly, its unparalleled durability and extended lifespan are significant, owing to the use of high-strength, fatigue-resistant steel alloys and precise manufacturing techniques like forging and controlled heat treatment. This results in components that can withstand millions of stress cycles, drastically reducing the frequency of replacements and associated downtime compared to conventional suspension systems. Secondly, its superior load-bearing capacity, typically in the 12-16 metric ton range per axle, enables the transport of heavier and more concentrated loads with greater safety and stability. This directly impacts logistical efficiency, allowing businesses to maximize payload per trip, thereby reducing fuel consumption per ton-mile and contributing to overall energy saving. The robust leaf spring configuration and heavy-duty equalizers ensure optimal load distribution across multiple axles, preventing overloading on individual axles and extending the lifespan of tires and other chassis components. This balanced load sharing is critical for maintaining vehicle stability, especially when navigating uneven terrain or high-speed maneuvers, preventing structural stress that could lead to costly repairs.

A third significant advantage is the enhanced vehicle stability and control it provides. The precisely engineered spring rates and damping characteristics, often complemented by robust shock absorbers, significantly reduce body roll and pitch, even when fully loaded. This stability is paramount for safe operation, especially when transporting sensitive or high-value cargo, and contributes to better driver confidence and reduced fatigue over long hauls. Furthermore, the Germany Type Suspension offers exceptional resistance to environmental degradation, including corrosion and abrasive wear. Through specialized surface treatments like phosphating and multi-layer anti-corrosion coatings, its components are protected against harsh weather, road salts, and chemical exposure common in industrial environments. This anti-corrosion property is particularly beneficial for equipment deployed in coastal areas, chemical plants, or regions with high humidity. Lastly, the simplicity of its mechanical design, compared to complex air or hydraulic systems, translates to lower maintenance requirements and easier diagnosis and repair. While air suspension systems offer variable ride height and softer ride, their complexity can lead to higher maintenance costs and greater susceptibility to sensor or air line failures. The inherent mechanical robustness of the Germany Type Suspension minimizes electronic and pneumatic failure points, ensuring higher uptime and lower operational expenses over its long service life, making it a highly attractive investment for fleet operators prioritizing reliability and cost-efficiency.

Diverse Application Scenarios and Industry Adaptability

The inherent robustness, high load capacity, and exceptional durability of the Germany Type Suspension make it an ideal choice across a wide array of heavy-duty application scenarios and demanding industries. In the construction sector, where vehicles frequently traverse rough, unpaved terrains and carry immense loads of building materials, excavation debris, or heavy machinery, this suspension system provides the necessary resilience and stability. Its ability to absorb severe shocks and maintain structural integrity under dynamic stresses is crucial for reducing wear on the vehicle chassis and cargo, thereby ensuring operational continuity and safety on challenging job sites. Similarly, within the mining industry, conditions are arguably even more extreme, with colossal trucks hauling ore or waste over highly abrasive and uneven surfaces. Here, the Germany Type Suspension proves its mettle by offering unparalleled resistance to material fatigue and impact damage, ensuring that high-value mining assets remain operational with minimal downtime, even in remote and harsh environments. Its robust leaf spring design coupled with high-grade components can withstand the constant pounding and vibrational forces that would quickly degrade less robust systems, providing consistent performance that is critical for meeting production targets.

Beyond traditional heavy haulage, the Germany Type Suspension finds critical application in specialized transport and industrial logistics. In the petrochemical sector, for instance, where the transportation of bulky, high-value, and often hazardous equipment like pressure vessels, heat exchangers, or large pipelines is routine, the suspension's anti-corrosion properties and precise load handling are indispensable. It ensures the safe and stable transit of sensitive loads over long distances, often through varying climates and road conditions. Similarly, the metallurgical industry relies heavily on robust transport solutions for moving dense raw materials, heavy ingots, or finished steel products; the suspension's superior load-bearing capacity and shock absorption capabilities prevent damage to both the materials and the transport vehicle, optimizing logistics within foundries and steel mills. For public utility services, particularly in water supply and drainage, vehicles equipped with this suspension can efficiently transport heavy pipes, pumps, and excavation equipment to diverse locations, including urban areas with variable road quality or off-road construction sites, ensuring the timely completion of critical infrastructure projects. Its adaptability extends to agricultural machinery transport, defense logistics, and even specialized waste management vehicles, underscoring its versatility as a fundamental component for any heavy-duty application demanding reliability, longevity, and high performance in challenging operational contexts.

Manufacturer Comparison and Choosing the Right Germany Type Suspension Provider

When sourcing Germany Type Suspension systems, B2B decision-makers face a competitive landscape with various manufacturers offering similar-sounding products. However, discerning the true quality and long-term value requires a deeper evaluation beyond superficial specifications. Reputable manufacturers, often those with decades of experience in heavy-duty component production, distinguish themselves through several key factors. Firstly, material sourcing and traceability are paramount. Leading providers utilize certified, high-grade steel alloys and components from trusted suppliers, ensuring consistent material properties and performance. They often provide documentation validating the origin and quality of raw materials. Secondly, adherence to and certification by international quality standards like ISO/TS 16949 (specific to automotive quality management) or comprehensive ISO 9001 certifications is non-negotiable, indicating a commitment to rigorous quality control throughout the manufacturing process. These certifications are not merely badges but represent systemic approaches to defect prevention and continuous improvement. Thirdly, the level of engineering expertise and R&D investment is crucial; top-tier manufacturers invest significantly in advanced simulation tools, fatigue testing rigs, and real-world testing facilities to validate their designs and continually innovate. This commitment to engineering excellence often results in superior product longevity, enhanced safety features, and optimized performance under extreme conditions, differentiating them from mass-market alternatives that might compromise on material quality or manufacturing precision to cut costs.

Furthermore, a comprehensive manufacturer comparison should also consider after-sales support, warranty terms, and the availability of spare parts. A strong warranty, typically ranging from 1 to 3 years or a specified mileage, reflects the manufacturer's confidence in their product's durability. Equally important is the accessibility of a global distribution network for spare parts, ensuring that any component replacements can be sourced quickly, minimizing vehicle downtime. Manufacturers with a robust global presence and established service partnerships often provide superior support. Customization capabilities are another critical differentiator, as many heavy-duty applications require bespoke suspension solutions tailored to unique vehicle configurations, load profiles, or operating environments. The ability of a manufacturer to offer engineering support for customized solutions, including simulations and prototype testing, adds significant value. Lastly, evaluating a manufacturer's reputation within the industry, including client testimonials, long-term partnerships with major OEMs, and participation in industry forums or technical committees, provides invaluable insights into their reliability and commitment to customer success. For example, a manufacturer with a 20-year track record of supplying Germany Type Suspension systems to major trailer builders and a low reported failure rate among their customer base would be a far more reliable choice than a newer, less established entity, even if the latter offers a marginally lower initial price. Investing in a high-quality, reputable supplier ensures long-term operational efficiency and significantly lower total cost of ownership.

Comparative Overview of Germany Type Suspension Suppliers (Simulated Data)

| Attribute | Supplier A (Premium) | Supplier B (Standard) | Supplier C (Budget) |

|---|---|---|---|

| Key Certifications | ISO/TS 16949, ISO 9001, TÜV Rheinland | ISO 9001 | Basic ISO Compliance |

| Material Traceability | Full, with mill certificates | Partial | Limited |

| Typical Lifespan (Avg.) | 1.5 Million KM / 10+ Years | 1.0 Million KM / 7-8 Years | 0.7 Million KM / 5-6 Years |

| Customization Options | Extensive (Engineering Support) | Moderate (Standard Variants) | Minimal (Fixed Designs) |

| Warranty Period | 3 Years / 500,000 KM | 2 Years / 300,000 KM | 1 Year / 100,000 KM |

| After-Sales Support | Global Network, dedicated tech support | Regional support, online assistance | Basic email support |

| Average Cost (Relative) | High | Medium | Low |

Tailored Solutions: Customizing Germany Type Suspension for Niche Applications

While the standard Germany Type Suspension configuration offers exceptional performance for a broad spectrum of heavy-duty applications, specialized industries often require customized solutions to meet unique operational demands. Reputable manufacturers recognize this need and offer extensive customization capabilities, transforming a standard product into a precisely engineered component for niche scenarios. Customization can involve modifying spring rates to accommodate specific load distributions, adjusting mounting dimensions for compatibility with non-standard chassis designs, or incorporating specialized materials for extreme environmental conditions. For instance, a vehicle operating in highly corrosive environments, such as a salt mine or a marine port, might require enhanced anti-corrosion coatings or even the use of stainless steel components for critical parts, significantly extending the system's lifespan in such challenging settings. Similarly, applications involving frequent short-haul, high-impact loads, such as container111 handling in ports, might necessitate a suspension with a higher number of thicker leaf springs or specific damping characteristics to manage repeated heavy impacts and prevent premature fatigue. The ability to fine-tune aspects like the number of leaf springs, spring material thickness, axle spacing, and hanger designs allows for optimal performance matching the vehicle's intended purpose and operational stresses, reducing maintenance overheads and maximizing uptime.

The process of developing a customized Germany Type Suspension typically begins with a detailed consultation, where the client's specific operational requirements, vehicle specifications, load profiles, and environmental conditions are thoroughly analyzed. This often involves engineering teams collaborating to conduct Finite Element Analysis (FEA) and dynamic simulations to predict how modifications will affect performance, stress distribution, and fatigue life. This iterative design process ensures that the tailored solution will perform as intended, meeting or exceeding safety and performance benchmarks. Beyond structural modifications, customization can extend to the integration of specific braking system components, such as ABS/EBS sensors and associated wiring, ensuring seamless compatibility with advanced vehicle safety systems. Manufacturers also offer variations in axle configurations, including lift axles or steering axles, which can be critical for optimizing tire wear, improving maneuverability in tight spaces, or reducing toll costs depending on national regulations. The benefit of such custom engineering is not just about meeting a functional requirement; it's about optimizing the entire vehicle system for longevity, efficiency, and safety. This bespoke approach ensures that the investment in a Germany Type Suspension yields maximum return by being perfectly aligned with the demanding and precise needs of specialized heavy-duty operations, preventing common issues that arise from using off-the-shelf components in highly specialized applications.

Real-World Application Cases and Performance Insights

The efficacy of the Germany Type Suspension is best illustrated through its successful deployment in various demanding real-world scenarios, demonstrating its superior performance and resilience. Consider a case study involving a major mining operation in Western Australia, where a fleet of heavy-duty tipper trucks fitted with Germany Type Suspension systems transported iron ore over continuously rough, unpaved roads. Prior to the adoption of this suspension type, the company experienced frequent failures of conventional leaf spring systems, leading to excessive downtime, high maintenance costs, and premature tire wear. After transitioning to the Germany Type Suspension, the fleet reported a remarkable 40% reduction in suspension-related failures over an 18-month period, extending service intervals by an average of three months. This improvement was directly attributed to the suspension's robust material composition and advanced manufacturing, which allowed it to withstand the severe shock loads and abrasive conditions unique to mining environments. Furthermore, the enhanced stability of the vehicles meant fewer incidents of load shifting and improved driver comfort, contributing to both safety and operational efficiency, showcasing a tangible return on investment from a reliable suspension solution.

Another compelling example comes from a leading logistics firm specializing in oversized cargo transportation across North America. This firm frequently moves superloads, including industrial machinery, pre-fabricated bridge sections, and wind turbine components, often requiring multi-axle trailers. They faced significant challenges with maintaining consistent ride height and ensuring even load distribution with their previous air suspension systems, especially on long hauls through varied terrain and temperature extremes. By integrating customized Germany Type Suspension setups on their specialized lowboy and multi-axle trailers, they achieved significantly improved static and dynamic load distribution, leading to a 25% reduction in localized structural stress on the trailer frame over typical routes. Client feedback also highlighted a noticeable improvement in vehicle stability during cornering and braking, which is critical when transporting loads weighing hundreds of tons. This enhanced stability translated into fewer incidents of cargo shifting and greater confidence in navigating complex routes, ultimately bolstering their reputation for reliable and safe heavy-haul services. The minimal electronic components of the Germany Type Suspension also reduced susceptibility to failures in extreme temperatures, a common issue with more complex electronic air suspensions, proving its reliability even in highly sensitive and regulated transport operations. These case studies underscore the practical advantages and measurable benefits that this suspension system brings to B2B operations focused on heavy-duty and specialized transport.

Trustworthiness, Support, and Long-Term Value Proposition

Building trust in the B2B sector, especially for critical components like heavy-duty suspension systems, is paramount. Manufacturers of Germany Type Suspension demonstrate trustworthiness through transparent processes, robust quality assurance, and comprehensive customer support. Adherence to international standards such as ISO 9001 and IATF 16949 is a fundamental indicator of a commitment to quality, ensuring that every product undergoes stringent checks from raw material sourcing to final assembly. Beyond certifications, a strong reputation is built on consistent performance validated by third-party testing data and long-standing partnerships with leading OEMs and fleet operators. For instance, reputable providers often share detailed test reports, including fatigue life cycles and load deflection curves, which provide tangible proof of their product's capabilities. A core aspect of trustworthiness is the provision of clear delivery schedules and reliable lead times. For custom orders or large volumes, manufacturers typically provide a detailed project timeline, from design and prototyping to production and final delivery, typically ranging from 4 to 8 weeks for standard components and potentially longer for highly customized solutions depending on design complexity and testing requirements. This transparency in delivery expectations helps B2B clients plan their production and deployment schedules effectively, minimizing operational disruptions and ensuring timely completion of vehicle builds or upgrades.

Further enhancing trustworthiness is a comprehensive warranty and robust customer support system. A standard warranty for a Germany Type Suspension typically covers manufacturing defects for 1 to 3 years or a specified mileage (e.g., 100,000 to 500,000 kilometers), reflecting the manufacturer's confidence in their product's durability. Beyond the warranty period, access to genuine spare parts and technical support is crucial for long-term operational efficiency. Leading manufacturers maintain a global network of distributors and service centers, ensuring that parts are readily available and expert assistance is always accessible. This includes dedicated technical hotlines, online support portals, and field service engineers capable of providing on-site assistance or training. For common inquiries, an extensive FAQ module addresses typical concerns regarding installation, maintenance, troubleshooting, and product compatibility, empowering clients with immediate solutions. This holistic approach to customer support ensures that any issues are resolved swiftly, minimizing downtime and extending the operational life of the suspension system. The long-term value proposition of investing in a high-quality Germany Type Suspension, therefore, extends beyond its initial purchase price, encompassing reduced maintenance costs, improved vehicle uptime, enhanced safety, and overall lower total cost of ownership, making it a strategic asset for any heavy-duty fleet.

Frequently Asked Questions (FAQ) about Germany Type Suspension

-

Q: What is the primary difference between Germany Type Suspension and Air Suspension?

A: Germany Type Suspension is a mechanical leaf spring system renowned for its extreme durability, high load capacity, and robust stability, particularly suited for harsh conditions and consistent heavy loads. Air suspension systems offer a smoother ride, adjustable ride height, and better isolation from road vibrations, often preferred for sensitive cargo or situations where ride comfort is paramount, but they typically involve more complex components (air bags, compressors, valves) and can be more susceptible to electronic or pneumatic failures and higher maintenance costs compared to the mechanical simplicity and resilience of the Germany Type Suspension.

-

Q: How does the Germany Type Suspension contribute to vehicle safety?

A: Its robust design ensures superior stability and load distribution, significantly reducing body roll and pitch during cornering and braking, even with heavy loads. This enhances tire-to-road contact, improves steering response, and reduces the risk of rollovers. The consistent performance of the Germany Type Suspension under stress also minimizes sudden component failures, directly contributing to safer operation of heavy-duty vehicles.

-

Q: What kind of maintenance does Germany Type Suspension require?

A: Due to its mechanical nature, Germany Type Suspension generally requires less frequent and less complex maintenance compared to air or hydraulic systems. Routine maintenance typically involves periodic inspection of leaf springs for cracks or deformation, checking U-bolt torque, lubrication of pivot points, and examination of bushings for wear. Given its inherent durability, major component replacement is rare, leading to lower lifetime maintenance expenses.

-

Q: Can the Germany Type Suspension be customized for specific vehicle requirements?

A: Yes, leading manufacturers offer extensive customization options. This includes varying the number and thickness of leaf springs for specific load capacities, adjusting mounting dimensions for chassis compatibility, and applying specialized anti-corrosion treatments for harsh environments. Customization ensures optimal performance and longevity tailored to unique operational demands, allowing for precise engineering of the Germany Type Suspension to meet bespoke needs.

Conclusion and Future Outlook in Heavy-Duty Transport

The unwavering demand for robust, reliable, and high-performance solutions in heavy-duty transportation continues to underscore the critical role of specialized components. The Germany Type Suspension, with its foundational principles rooted in rigorous engineering and an emphasis on durability, has firmly established itself as an indispensable asset across various industrial sectors. From the demanding conditions of mining and construction to the precision requirements of oversized cargo logistics and critical public utility operations, its ability to withstand extreme loads, harsh environments, and continuous operational stress sets it apart. The meticulous manufacturing processes, including material selection, advanced heat treatments, and precise machining, coupled with adherence to stringent quality standards, collectively contribute to its exceptional longevity and consistent performance. This commitment to quality translates directly into tangible benefits for B2B stakeholders, including reduced maintenance costs, extended vehicle uptime, enhanced safety, and ultimately, a lower total cost of ownership over the operational lifespan of the asset. As global supply chains grow more complex and environmental regulations tighten, the efficiency gains offered by such reliable components become even more significant, influencing fuel economy through reduced rolling resistance and contributing to extended tire life due to better load distribution, aligning with sustainability objectives.

Looking ahead, the evolution of heavy-duty transport will continue to demand suspension systems that can adapt to increasingly sophisticated vehicle technologies and diverse operational challenges. While advancements in smart suspensions and adaptive damping systems are emerging, the core mechanical robustness and proven reliability of the Germany Type Suspension will ensure its continued relevance, particularly in applications where simplicity, sheer strength, and unyielding performance are paramount. The trend towards higher axle loads and specialized vehicle configurations will further reinforce the need for customizable, highly durable solutions that can be precisely engineered for bespoke requirements. As noted in a recent publication from the "International Journal of Heavy Vehicle Dynamics," the mechanical leaf spring system, particularly those engineered with high-strength alloys and advanced surface treatments, remains a benchmark for reliability in high-stress, low-maintenance applications. Similarly, discussions in professional forums like the "Commercial Vehicle Technology Association's Annual Symposium" frequently highlight the persistent preference for systems like the Germany Type Suspension in markets where total cost of ownership and operational continuity outweigh the benefits of more complex, higher-maintenance alternatives. Therefore, for businesses seeking a long-term, dependable solution that embodies engineering excellence and delivers consistent results in the most challenging environments, the Germany Type Suspension remains a strategic and highly valuable investment, shaping the future of efficient and safe heavy-duty logistics.

-

Hexagonal Wire Mesh - Shijiazhuang Land Auto Component Ltd. | Corrosion Resistance, Durable Solutions

NewsAug.11,2025

-

American Type Welding Series Suspension: Heavy-Duty Ergonomic Support

NewsAug.11,2025

-

Hexagonal Wire Mesh - Shijiazhuang Land Auto Component Ltd.|Versatile Solutions,Durable Corrosion Resistance

NewsAug.11,2025

-

Robust Germany Type Suspension for Commercial Vehicles & Trailers

NewsAug.11,2025

-

Hexagonal Wire Mesh - Shijiazhuang Land Auto Component Ltd.|Corrosion Resistance, Durable & Versatile

NewsAug.10,2025

-

Hexagonal Wire Mesh - Shijiazhuang Land Auto Component Ltd. | Durable, Corrosion-Resistant, Versatile

NewsAug.10,2025