- afrikansk

- albansk

- amharisk

- arabisk

- armensk

- aserbajdsjansk

- baskisk

- hviderussisk

- bengalsk

- bosnisk

- bulgarsk

- catalansk

- Cebuano

- Kina

- Kina (Taiwan)

- korsikansk

- kroatisk

- tjekkisk

- dansk

- hollandsk

- engelsk

- Esperanto

- estisk

- finsk

- fransk

- frisisk

- galicisk

- georgisk

- tysk

- græsk

- Gujarati

- haitisk kreol

- Hausa

- hawaiiansk

- hebraisk

- Nix

- Miao

- ungarsk

- islandsk

- igbo

- indonesisk

- irsk

- italiensk

- japansk

- javanesisk

- Kannada

- kasakhisk

- Khmer

- rwandisk

- koreansk

- kurdisk

- kirgisisk

- Arbejdskraft

- latin

- lettisk

- litauisk

- luxembourgsk

- makedonsk

- Malgashi

- malaysisk

- Malayalam

- maltesisk

- Maori

- Marathi

- mongolsk

- Myanmar

- nepalesisk

- Norsk

- Norsk

- occitansk

- Pashto

- persisk

- Polere

- portugisisk

- Punjabi

- rumænsk

- Russisk

- samoansk

- skotsk gælisk

- serbisk

- engelsk

- Shona

- Sindhi

- singalesiske

- slovakisk

- slovensk

- Somali

- spansk

- sundanesisk

- Swahili

- svensk

- Tagalog

- tadsjikisk

- Tamil

- tatarisk

- Telugu

- Thai

- tyrkisk

- turkmenske

- ukrainsk

- Urdu

- Uighur

- usbekisk

- vietnamesisk

- walisisk

- Hjælp

- Jiddisch

- Yoruba

aug . 23, 2025 00:54 Tilbage til listen

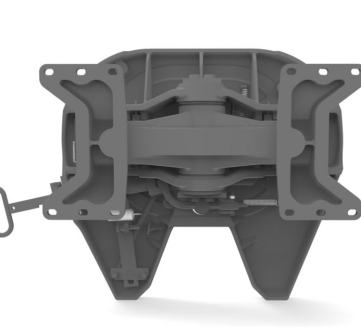

Preventing Rust on Fifth Wheel Plates for Semi-Trucks

Rust is the nemesis of any metal component, and sættevognsplader til semi-lastbiler are no exception. These critical parts, along with 5th wheel plate for semi og semi 5. hjulstræk components, are constantly exposed to moisture, road salt, and debris—all of which accelerate corrosion. Left unchecked, rust can weaken the structural integrity of these parts, compromising safety and shortening their lifespan. Shijiazhuang Land Auto Component Ltd., a leading producer of cast steel fifth wheels, understands the importance of rust prevention. With advanced production technology and a focus on durable components—like their high-quality cast steel traction seats with stable performance—their expertise aligns with the need to keep sættevognsplader til semi-lastbiler in top condition. This guide will walk you through effective strategies to prevent rust and maintain these essential parts.

Regular Cleaning of Fifth Wheel Plates for Semi-Trucks

- Remove Surface Debris: Start by rinsing sættevognsplader til semi-lastbiler with high-pressure water to dislodge dirt, mud, and road salt. Use a soft-bristled brush to scrub away caked-on grime, paying special attention to crevices where debris tends to accumulate—these areas are prime spots for rust to take hold.

- Use Mild Detergents: For tougher stains, apply a mild, pH-neutral detergent to the 5th wheel plate for semi. Avoid harsh chemicals like bleach or acid-based cleaners, which can strip protective coatings and accelerate corrosion. Scrub gently and rinse thoroughly to remove all soap residue.

- Dry Completely: After cleaning, use a clean, dry cloth to wipe down the semi 5. hjulstræk and fifth wheel plate. Moisture left on the surface is a major rust trigger, so ensure all areas—including hinges and moving parts—are completely dry before moving on to protection steps.

Protective Coatings for 5th Wheel Plate for Semi

- Apply Rust Inhibitors: A high-quality rust inhibitor spray or paste is a must for 5th wheel plate for semi Look for products containing zinc or phosphate, which form a barrier between the metal and moisture. Apply a thin, even coat to all exposed surfaces, reapplying every 3–6 months depending on usage.

- Use Paint or Enamel: For long-term protection, consider painting the sættevognsplader til semi-lastbiler with a rust-resistant enamel or epoxy paint. Clean and sand the surface lightly to create a rough texture for better adhesion, then apply two coats of paint, allowing each to dry fully. This creates a durable barrier against the elements.

- Lubricate Moving Parts: The hinges, pins, and locking mechanisms of the semi 5. hjulstræk need special attention. Apply a heavy-duty, waterproof lubricant—like lithium-based grease—to these parts. Not only does this prevent rust, but it also ensures smooth operation, reducing wear and tear that can expose fresh metal to corrosion.

Comparing Rust Prevention Methods for Semi 5th Wheel Hitch Components

|

Method |

Application for Semi 5th Wheel Hitch |

Fordele |

Ulemper |

|

Rust Inhibitor Sprays |

Easy to apply to all surfaces, including tight spaces. |

Quick drying, affordable, ideal for regular maintenance. |

Requires frequent reapplication (every 3–6 months). |

|

Epoxy Paint |

Applied to clean, sanded sættevognsplader til semi-lastbiler for a durable finish. |

Long-lasting (up to 2–3 years), excellent barrier against moisture. |

Requires more prep work, may chip if not applied properly. |

|

Zinc Coating |

Factory-applied or professional dip coating for 5th wheel plate for semi. |

Provides sacrificial protection (zinc corrodes instead of the metal). |

Can be expensive to apply professionally; may wear thin in high-friction areas. |

|

Waterproof Lubricants |

Used on moving parts of the semi 5. hjulstræk like pins and locks. |

Prevents rust while ensuring smooth operation. |

Can attract dirt, requiring more frequent cleaning. |

This table compares different rust prevention methods, helping you choose the best approach for your sættevognsplader til semi-lastbiler.

Storage and Environmental Protection for Fifth Wheel Plates for Semi-Trucks

- Cover When Not in Use: If the semi-truck will be parked for an extended period, cover the sættevognsplader til semi-lastbiler with a waterproof, breathable cover. This shields the plate from rain, snow, and direct sunlight—all of which contribute to rust—while allowing trapped moisture to escape.

- Park in Sheltered Areas: Whenever possible, park the truck in a garage or covered lot to protect the 5th wheel plate for semi from the elements. If outdoor parking is necessary, choose a spot away from puddles or areas where water pools, as standing water accelerates corrosion.

- Inspect After Exposure to Harsh Conditions: After driving in rain, snow, or salty environments, take extra time to inspect and clean the semi 5. hjulstræk and fifth wheel plate. Road salt is particularly corrosive, so a quick rinse and dry can prevent long-term damage.

Fifth Wheel Plates for Semi-Trucks FAQS

How Often Should I Inspect Fifth Wheel Plates for Semi-Trucks for Rust?

Inspect sættevognsplader til semi-lastbiler at least once a week for early signs of rust, such as small reddish spots or flaking paint. After exposure to harsh conditions—like snowstorms or coastal driving—inspect immediately to catch and address rust before it spreads.

Can Rust on 5th Wheel Plate for Semi Be Repaired?

Yes, small rust spots on a 5th wheel plate for semi can be repaired by sanding the area to remove rust, applying a rust converter to neutralize remaining corrosion, and then touching up with paint or rust inhibitor. However, extensive rust that has weakened the metal requires plate replacement.

Is It Safe to Use Used Fifth Wheel Plates for Semi-Trucks?

Used sættevognsplader til semi-lastbiler can be safe if they’re free of rust and structural damage. Thoroughly inspect for rust, cracks, or warping before installation, and apply fresh protective coatings to ensure longevity. Avoid plates with deep rust pits, as they may compromise safety.

What’s the Best Lubricant for Semi 5th Wheel Hitch to Prevent Rust?

A lithium-based or calcium sulfonate grease is best for semi 5. hjulstræk components. These lubricants are waterproof, resist high temperatures, and provide a protective barrier against moisture—key for preventing rust in moving parts.

Where Can I Get Quality Replacement Fifth Wheel Plates for Semi-Trucks?

Shijiazhuang Land Auto Component Ltd. offers high-quality cast steel semi 5. hjulstræk components, including plates designed to resist rust and withstand heavy use. Their expertise in durable, reliable parts makes them a trusted source. Visit their website to explore replacement options and rust prevention solutions.

-

Jost Fifth Wheel Weight Capacity Explained

NyhederAug.23,2025

-

Preventing Rust on Fifth Wheel Plates for Semi-Trucks

NyhederAug.23,2025

-

Light Weight Fifth Wheel Tire Care Guide

NyhederAug.23,2025

-

Why Off-road Trailers Need a Heavy Duty Fifth Wheel

NyhederAug.23,2025

-

Step-by-Step Guide to Lubricating Holland 5th Wheel Parts

NyhederAug.23,2025

-

How Jost Fifth Wheels Enhance Trailer Stability

NyhederAug.23,2025