Abu . 26, 2025 00:20 Back to list

Durable Semi Trailer Kingpin Plate Replacement for Safety

Understanding the Critical Role of Semi Trailer Kingpin Plate Replacement

In the demanding world of commercial trucking, the reliability and safety of every component are paramount. Among these, the fifth wheel assembly, particularly the kingpin plate, stands as a pivotal connection between the tractor and the trailer. The integrity of this interface directly impacts vehicle stability, operational safety, and overall fleet efficiency. When wear, damage, or degradation compromise this critical component, a precise and robust semi trailer kingpin plate replacement becomes not just a maintenance task, but a strategic investment in safety and longevity. This article delves into the technical intricacies, industry best practices, and strategic considerations for selecting and implementing high-quality kingpin plate solutions in B2B heavy-duty operations.

Industry Trends and the Evolving Landscape

The heavy-duty transport industry is continuously evolving, driven by advancements in materials science, manufacturing techniques, and increasingly stringent safety regulations. Current trends emphasize lighter yet stronger materials, enhanced corrosion resistance, and predictive maintenance capabilities to minimize downtime. The demand for durable and precisely engineered components, such as a high-quality semi trailer kingpin plate replacement, is at an all-time high. Fleet operators are looking beyond initial cost, focusing on total cost of ownership (TCO) which includes factors like extended service life, reduced maintenance intervals, and improved fuel efficiency due to weight optimization. Furthermore, the integration of advanced sensors for real-time monitoring of component health is gaining traction, promising a future where predictive maintenance becomes the norm, further highlighting the need for components that can withstand rigorous operational demands without premature failure. The importance of reliable solutions extends to peripheral components like the semi trailer kingpin lock, which works in conjunction with the kingpin plate to ensure secure coupling.

Technical Specifications and Material Science

A superior semi trailer kingpin plate replacement is defined by its adherence to stringent technical specifications and the intelligent selection of materials. Kingpin plates are typically manufactured from high-tensile steel alloys, such as SAE 1045 or specific proprietary alloys, chosen for their exceptional strength-to-weight ratio and fatigue resistance. These materials undergo sophisticated metallurgical treatments to enhance their mechanical properties.

Key parameters include:

- Yield Strength: The maximum stress a material can withstand without permanent deformation. For kingpin plates, values often exceed 500 MPa.

- Tensile Strength: The maximum stress a material can withstand while being stretched or pulled before breaking. Typically above 700 MPa.

- Hardness: Measured in Brinell (HB) or Rockwell (HRC) units, indicating resistance to indentation and wear, crucial for the contact surface.

- Impact Resistance: The ability to absorb energy and deform plastically without fracturing, vital for absorbing dynamic loads during coupling and transit.

- Corrosion Resistance: Achieved through material composition, surface treatments, or protective coatings, prolonging service life in harsh environments.

- Dimensional Accuracy: Critical for seamless integration with the fifth wheel and kingpin. Adherence to SAE J885 standards for kingpin dimensions (e.g., 2-inch or 3.5-inch) is non-negotiable.

Here is a typical specification table for high-performance kingpin plates:

| Parameter | Specification (Typical High-Performance) | Significance |

|---|---|---|

| Material Grade | High-Tensile Alloy Steel (e.g., SAE 1045, 4140) | Ensures optimal strength and durability under heavy loads. |

| Yield Strength | ≥ 550 MPa (80,000 psi) | Resistance to permanent deformation. |

| Tensile Strength | ≥ 750 MPa (109,000 psi) | Resistance to fracture under extreme tension. |

| Hardness | 220-280 HB (Brinell) | Wear resistance and extended service life. |

| Corrosion Protection | Electrophoretic deposition (EPD) or powder coating | Prevents rust and degradation in harsh weather/road conditions. |

| Kingpin Diameter Standard | 2-inch (50.8 mm) per SAE J885, or 3.5-inch (89 mm) | Ensures compatibility with standard fifth wheels. |

| Maximum Rated Vertical Load | Up to 25,000 kg (55,000 lbs) | Capacity to handle diverse trailer loads securely. |

The Manufacturing Process Flow for Kingpin Plate Replacement

The production of a high-quality semi trailer kingpin plate replacement is a multi-stage process demanding precision and strict quality control. The manufacturing journey typically involves:

- Material Selection and Preparation: Sourcing high-grade alloy steel (e.g., 4140, 1045) verified by material certifications. The raw material is then cut to approximate dimensions.

- Forging or Casting:

- Forging: Involves shaping the metal using localized compressive forces, often through hammer or press. This process refines grain structure, improving strength and fatigue resistance, making it ideal for critical components like kingpin plates.

- Casting: Pouring molten metal into a mold. While less expensive, cast parts may have lower mechanical properties unless subjected to further heat treatment and inspection. For high-stress applications, forging is often preferred.

- Heat Treatment: A crucial step, typically involving quenching and tempering. This process optimizes the material's hardness, toughness, and ductility, significantly improving its service life and resistance to wear and impact.

- CNC Machining: Precision machining to achieve exact dimensions, surface finishes, and bore accuracy for the kingpin. Computer Numerical Control (CNC) ensures consistency and adherence to tight tolerances (e.g., ±0.05 mm), which is vital for proper fitment and performance with the fifth wheel.

- Welding (for plate attachment): If the kingpin plate is a separate component welded to a trailer sub-frame, controlled welding procedures (e.g., GMAW or SMAW) are employed, often followed by stress relief.

- Surface Treatment/Coating: Application of protective layers, such as electrophoretic deposition (EPD) or powder coating, to provide superior corrosion resistance, especially important for components exposed to road salts and environmental elements.

- Quality Control & Testing: Rigorous inspections at various stages, including:

- Dimensional Inspection: Using calipers, micrometers, CMMs to verify adherence to design specifications.

- Non-Destructive Testing (NDT): Magnetic particle inspection, ultrasonic testing, or radiographic testing to detect internal flaws, cracks, or material inconsistencies.

- Material Hardness Testing: Verifying the efficacy of heat treatment.

- Fatigue Testing: Simulating repeated stress cycles to ensure long-term durability.

- Compliance: Adherence to international standards such as ISO 9001 for quality management and ANSI/SAE standards for component design and performance.

This meticulous process ensures that each semi trailer kingpin plate replacement meets the highest standards of safety and operational performance, offering an expected service life of 5-10 years under normal operating conditions, significantly reducing the need for premature replacements and associated downtime.

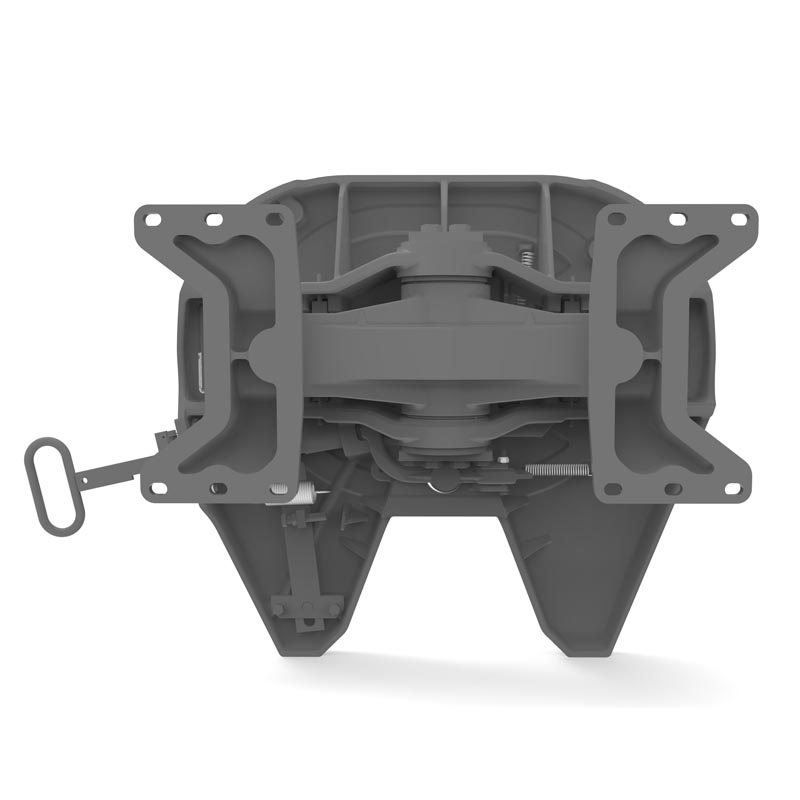

Image: High-precision manufacturing ensures robust semi trailer kingpin plate replacement.

Technical Advantages and Performance Metrics

Investing in a premium semi trailer kingpin plate replacement yields significant technical advantages. Modern designs and materials not only meet but often exceed OEM specifications, translating into enhanced performance metrics and operational benefits for fleet managers and operators.

- Enhanced Durability and Fatigue Resistance: Through advanced heat treatments and forging processes, plates exhibit superior resistance to repetitive stress cycles, reducing the likelihood of fatigue cracks and extending operational life. This is crucial for heavy haulage and long-distance transport.

- Superior Corrosion Resistance: Specialized coatings (e.g., EPD, zinc phosphate, or powder coat) provide robust protection against road salts, moisture, and chemical exposure, a common issue in many operating environments, thereby preserving structural integrity.

- Optimized Weight Distribution: Precision engineering allows for material optimization, potentially reducing overall trailer weight without compromising strength. This can contribute to marginal fuel savings over the lifespan of the trailer (energy saving) and allow for greater payload capacity.

- Reduced Maintenance & Downtime: A durable kingpin plate minimizes wear on the fifth wheel, reducing the need for frequent lubrication and inspections. This directly translates to lower maintenance costs and significantly less unscheduled downtime, boosting fleet availability.

- Improved Safety Profile: A structurally sound kingpin plate is fundamental to preventing accidental trailer decoupling, a critical safety concern. High-quality replacements ensure that the connection remains secure even under severe dynamic loads and braking forces.

- Compliance with Standards: Adherence to international standards such as SAE J885, ISO, and DOT regulations ensures that the replacement component is compatible with existing equipment and meets all safety and performance benchmarks.

These advantages are not merely theoretical; they translate into tangible cost savings and improved operational efficiency, making the choice of a high-quality semi trailer kingpin plate replacement a strategic decision for any fleet operator.

Application Scenarios and Target Industries

The need for reliable semi trailer kingpin plate replacement extends across a diverse range of industries, each presenting unique challenges and operational demands. The target industries for premium kingpin plate solutions are those where uptime, safety, and heavy-duty performance are non-negotiable.

- Logistics & Freight Transport: General freight carriers, including LTL (Less Than Truckload) and FTL (Full Truckload) operations, demand robust components that can withstand constant coupling/uncoupling and varied road conditions across thousands of miles annually.

- Construction & Mining: Trailers transporting heavy machinery, aggregates, or raw materials operate in extremely harsh environments, often off-road. Kingpin plates here face high impact loads, abrasive dust, and extreme weather, necessitating superior strength and corrosion resistance.

- Oil & Gas / Petrochemical: Specialized trailers for transporting fuels, chemicals, or oversized equipment in the energy sector require components capable of handling immense static and dynamic loads, often in remote or corrosive environments. Corrosion resistance is a critical advantage.

- Agriculture & Forestry: Hauling agricultural products, timber, or heavy farm equipment requires kingpin plates that can endure uneven terrain and seasonal weather extremes.

- Waste Management: Refuse haulers and recycling trucks face continuous heavy loading cycles and frequent stops, putting immense stress on the fifth wheel assembly.

- Specialized Transport (e.g., Wind Energy, Oversized Loads): For transporting wind turbine blades, transformer cores, or other super-heavy, oversized cargo, the kingpin plate is under immense, sustained stress. Precision-engineered solutions are vital for stability and control.

In these scenarios, the ability of a kingpin plate to resist corrosion, handle extreme loads, and maintain structural integrity directly translates to operational safety, compliance, and reduced operational costs. The choice of reliable components, including the kingpin plate and often related parts like the semi trailer landing gear manufacturers supply, is fundamental to continuous operation.

Image: Kingpin plates are vital across diverse heavy-duty applications.

Customized Solutions for Unique Demands

While standard semi trailer kingpin plate replacement products meet the needs of many applications, certain specialized operations require bespoke solutions. Customization can involve modifying material grades, dimensions, bolt patterns, or surface treatments to align with specific trailer designs, unique load requirements, or extreme environmental conditions. For instance, trailers operating in highly corrosive marine environments might require enhanced anti-corrosion treatments or even specialized stainless steel alloys. Similarly, for extremely heavy-haul applications, a kingpin plate might need additional reinforcement or a larger diameter kingpin (e.g., 3.5-inch) than the standard 2-inch.

Professional manufacturers collaborate closely with clients to understand their precise operational context, employing CAD/CAM technologies and FEA (Finite Element Analysis) to design and validate custom kingpin plate solutions. This ensures optimal performance, safety, and compatibility with the existing fleet infrastructure, providing a perfectly tailored semi trailer kingpin plate replacement that minimizes stress concentrations and maximizes service life under specific operating parameters.

Vendor Comparison: Selecting the Right Partner

Choosing the right vendor for your semi trailer kingpin plate replacement needs is a critical decision that impacts fleet safety, uptime, and long-term costs. While many suppliers offer kingpin plates, not all adhere to the same rigorous standards of quality, engineering, and support. A comprehensive vendor comparison should evaluate several key aspects:

- Certifications: Look for ISO 9001 certified manufacturers who adhere to SAE J885 standards and relevant national regulations.

- Material Quality: Inquire about material sourcing, metallurgical composition, and the availability of material test reports.

- Manufacturing Processes: Understand if they utilize advanced techniques like forging, CNC machining, and controlled heat treatments.

- Testing & QA: Evaluate their internal quality assurance protocols, including NDT capabilities and fatigue testing.

- Technical Support & Expertise: Assess their ability to provide expert advice, technical documentation, and support for complex applications or custom solutions.

- Warranty & After-Sales Service: A strong warranty reflects confidence in product quality and a commitment to customer satisfaction.

Here’s a comparison highlighting key differentiators:

| Feature | Premium Vendor (e.g., Land Fifth Wheel) | Standard Supplier |

|---|---|---|

| Material Sourcing | Certified High-Tensile Alloy Steel (e.g., 4140, 1045) | Generic carbon steel, often without specific alloy verification |

| Manufacturing Process | Forging, CNC machining, precise heat treatment (quenching & tempering) | Basic machining, less controlled heat treatment, potentially casting only |

| Corrosion Protection | Advanced coatings (EPD, powder coat), 500+ hour salt spray test | Basic primer/paint, limited salt spray resistance |

| Quality Assurance | ISO 9001, NDT, dimensional CMM, fatigue testing, material certs | Basic visual inspection, limited material testing |

| Service Life (Estimated) | 5-10+ years under specified conditions | 2-4 years, higher risk of premature failure |

| Technical Support | Expert engineering support, customized solutions, detailed documentation | Limited, basic product information |

Image: Rigorous testing ensures every semi trailer kingpin plate replacement meets high standards.

Real-World Application Case Studies

The tangible benefits of a quality semi trailer kingpin plate replacement are best illustrated through real-world applications.

Case Study 1: Long-Haul Freight Fleet

A major North American long-haul logistics company experienced frequent kingpin plate wear and minor deformations on their older trailer fleet, leading to increased maintenance costs and vehicle downtime. After implementing a proactive replacement program using high-tensile steel semi trailer kingpin plate replacement units with advanced corrosion protection, they observed:

- 25% Reduction in Downtime: Due to extended component life and reduced need for corrective maintenance.

- 15% Decrease in Annual Maintenance Costs: Related to fifth wheel assembly components.

- Improved Driver Confidence: Enhanced safety perception due to a more robust and reliable coupling system.

Case Study 2: Construction Materials Transport

A regional construction firm specializing in hauling heavy aggregates faced challenges with kingpin plate failures due to high impact loads and abrasive conditions. They opted for customized kingpin plates featuring reinforced designs and specialized hard-wearing surface treatments. The results included:

- Doubled Service Life: From an average of 3 years to over 6 years, even under severe operating conditions.

- Elimination of Structural Failures: No reported kingpin plate structural failures after two years of deployment.

- Enhanced Operational Continuity: Reduced unexpected breakdowns, keeping project timelines on track.

Image: A robust kingpin plate is essential for heavy-duty applications.

Ensuring Quality and Reliability: EEAT for B2B Components

For B2B buyers, Google's EEAT (Experience, Expertise, Authoritativeness, Trustworthiness) framework is crucial in evaluating suppliers of critical components like a semi trailer kingpin plate replacement.

- Expertise: Demonstrated through deep technical knowledge of metallurgy, fatigue analysis, and engineering standards (e.g., SAE J885). Companies with in-house R&D and engineering teams, as well as those with extensive experience in manufacturing fifth wheel components for decades, exemplify this.

- Experience: Reflected in a track record of successful deployments across various industries and positive customer feedback from major fleet operators. Service case details and long-term performance data from diverse operational environments provide tangible proof.

- Authoritativeness: Established through certifications (e.g., ISO 9001:2015), partnerships with leading trailer and truck manufacturers, and adherence to international regulatory bodies. Data-backed analyses, publicly available test reports, and compliance with industry-specific quality norms (e.g., CE, DOT) are key indicators. Many leading manufacturers of semi-trailer components, including those specializing in semi trailer landing gear manufacturers, often hold similar certifications and display their quality commitment.

- Trustworthiness: Built upon transparency in manufacturing processes, clear warranty policies, reliable lead times, and comprehensive customer support. Companies that provide detailed product documentation and accessible communication channels foster trust.

Choosing a supplier that consistently demonstrates these EEAT pillars ensures not just a product purchase, but a partnership grounded in quality and reliability.

Trustworthiness: FAQs, Lead Time, Warranty, & Support

Frequently Asked Questions (FAQs)

- Q: What indicates that a kingpin plate needs replacement?

- A: Visible wear, cracks, pitting, deformation, or excessive play in the fifth wheel connection are clear indicators. Regular inspections during preventative maintenance should identify these issues.

- Q: Are all kingpin plates compatible?

- A: No. While 2-inch and 3.5-inch kingpins are standard, the plate dimensions, bolt patterns, and material specifications vary. Always consult trailer specifications or the manufacturer for correct compatibility.

- Q: How does a premium kingpin plate reduce overall operating costs?

- A: By extending service life, reducing unscheduled downtime for repairs, minimizing wear on the fifth wheel, and potentially offering marginal fuel savings through weight optimization, premium plates contribute to a lower total cost of ownership.

Lead Time & Fulfillment

Standard semi trailer kingpin plate replacement units typically have a lead time of 2-4 weeks, depending on order volume and specific requirements. Expedited shipping options are often available for urgent requirements. For customized solutions, lead times may extend to 6-8 weeks, allowing for design, prototyping, and rigorous testing. We maintain strategic inventory levels of high-demand products to support immediate fulfillment where possible.

Warranty Commitments

Our semi trailer kingpin plate replacement products are backed by a comprehensive 2-year manufacturer's warranty against defects in material and workmanship. This commitment underscores our confidence in the quality and durability of our products, providing peace of mind to our clients. Full warranty terms and conditions are available upon request.

Customer Support

Our dedicated customer support team is available via phone, email, and live chat to assist with product selection, technical inquiries, order tracking, and after-sales support. We offer in-depth technical documentation and installation guides, and our engineering team is available for consultation on complex applications or custom requirements. Our goal is to ensure seamless integration and optimal performance for every product.

Image: Reliable support ensures seamless semi trailer kingpin plate replacement.

Conclusion

The selection and implementation of a high-quality semi trailer kingpin plate replacement are critical for maintaining the safety, efficiency, and longevity of any heavy-duty fleet. By understanding the intricate manufacturing processes, adhering to rigorous technical specifications, and partnering with reputable suppliers who demonstrate strong EEAT principles, B2B decision-makers can make informed choices that yield significant operational advantages and reduce overall total cost of ownership. Investing in superior components is not merely a cost, but a strategic imperative for continuous, reliable, and safe transportation operations.

References

- SAE International. (2018). SAE J885: Kingpin Performance. Retrieved from sae.org.

- ISO. (2015). ISO 9001:2015 Quality management systems – Requirements. Retrieved from iso.org.

- Trucking Efficiency Council. (2020). Best Practices Guide for Fleet Maintenance. Retrieved from truckingefficiency.org.

-

Durable Semi Trailer Kingpin Plate Replacement for Safety

NewsAug.26,2025

-

Germany Type Suspension: Heavy-Duty, Reliable for Trucks & Trailers

NewsAug.25,2025

-

Heavy-Duty 5th Wheel Hitch for Sale - Secure Your Towing!

NewsAug.24,2025

-

Durable Germany Type Suspension for Heavy Duty Trucks & Trailers

NewsAug.23,2025

-

American Type Welding Suspension Series: Strong, Reliable Hooks

NewsAug.22,2025

-

Hezhen 1-3mm Luminous Stone- Shijiazhuang Land Auto Component Ltd.|Durability&High Luminosity

NewsAug.18,2025