Aug . 10, 2025 00:40 Back to list

Semi Trailer Kingpin Plate Replacement - Durable Parts

The Crucial Role and Advanced Solutions in semi trailer kingpin plate replacement

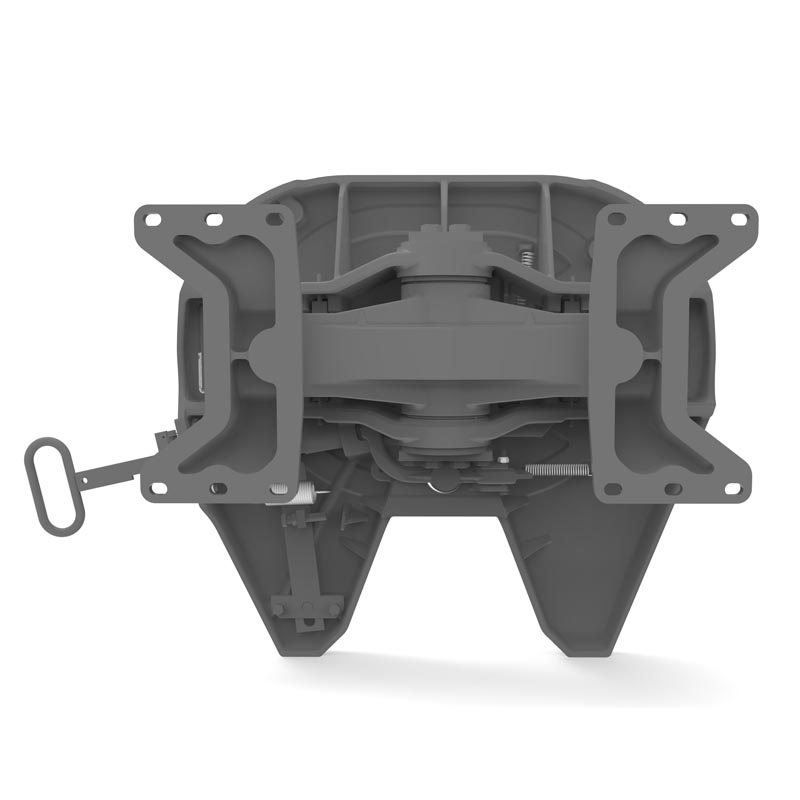

In the demanding world of commercial trucking and logistics, the integrity of every component plays a pivotal role in ensuring operational efficiency, safety, and profitability. Among these critical elements, the kingpin plate of a semi-trailer stands as a fundamental interface, forming the mechanical link between the tractor's fifth wheel and the trailer itself. This robust steel plate, typically designed to withstand immense dynamic loads and constant friction, is essential for stable and secure coupling. Its primary function is to house and support the kingpin, a precisely engineered vertical steel pin that locks into the fifth wheel, facilitating articulation and transferring braking and acceleration forces between the two vehicles. The proper functioning of this plate is non-negotiable; any compromise in its structural integrity or dimensional accuracy can lead to severe safety hazards, including trailer detachment, loss of control, or catastrophic equipment failure, leading to significant downtime, costly repairs, and potential legal ramifications. As such, the proactive maintenance and timely semi trailer kingpin plate replacement become paramount considerations for fleet operators and maintenance managers. This comprehensive guide delves into the intricate aspects of kingpin plate technology, from its manufacturing processes and technical specifications to its application advantages and the critical considerations for replacement, aiming to equip B2B decision-makers with the insights necessary to optimize their fleet's performance and longevity. We will explore the latest industry trends, highlight the importance of adhering to stringent quality standards, and provide a framework for selecting the most reliable components in a market increasingly driven by demand for enhanced safety and durability.

The significance of the kingpin plate extends beyond mere mechanical connection; it directly influences the dynamic stability of the entire tractor-trailer combination. A worn or damaged plate can introduce excessive play in the coupling, leading to uncomfortable jarring for the driver, uneven tire wear, and increased stress on other chassis components. Moreover, in long-haul operations where trailers are frequently coupled and uncoupled, the kingpin plate endures thousands of cycles of engagement and disengagement, alongside constant rotational and translational movements during turns and braking. This continuous stress necessitates a material and design that can withstand abrasion, impact, and fatigue. The evolution of materials science and advanced manufacturing techniques has led to kingpin plates that offer superior wear resistance and extended service life, reducing the frequency of replacements and the associated operational disruptions. Understanding the signs of wear, the appropriate inspection protocols, and the benefits of high-quality replacement parts is fundamental to maintaining a safe and efficient fleet. This article will provide a detailed exposition on these elements, integrating expert perspectives and industry best practices to inform your strategic procurement and maintenance decisions, emphasizing the proactive measures that can prevent costly failures and ensure the uninterrupted flow of goods.

Navigating Industry Trends and Market Dynamics in Semi-Trailer Components

The semi-trailer industry is experiencing a dynamic period, driven by escalating global trade volumes, the proliferation of e-commerce, and increasing regulatory pressure for safety and environmental sustainability. These overarching trends directly impact the demand and technological advancements in critical components like the kingpin plate. The shift towards higher load capacities and longer service intervals for trailers necessitates components engineered for extreme durability and reduced maintenance. Innovations in material science, such as the use of high-strength low-alloy (HSLA) steels and advanced heat treatment processes, are enabling manufacturers to produce kingpin plates that are simultaneously lighter and stronger, contributing to improved fuel efficiency and payload capacity. Furthermore, the emphasis on driver safety and cargo security has spurred developments in related components, particularly the semi trailer kingpin lock mechanisms. Modern kingpin locks often feature more robust designs, advanced locking indicators, and sometimes even sensor integration for real-time coupling status monitoring, enhancing operational safety and providing peace of mind for operators. The integration of such technologies reflects a broader industry movement towards smart logistics and intelligent components that can communicate critical operational data, allowing for predictive maintenance and optimized fleet management. This technological convergence ensures that not only the kingpin plate but also its surrounding systems are designed for maximum reliability and safety in an increasingly interconnected transport ecosystem. The ongoing evolution of trailer designs, from specialized tankers for the petrochemical industry to advanced refrigerated units for food logistics, further underscores the need for adaptable and high-performance kingpin solutions that can meet diverse operational requirements while adhering to the most stringent safety standards globally.

Market dynamics are also influenced by geopolitical factors, supply chain resilience, and the fluctuating costs of raw materials. Manufacturers of semi trailer kingpin plate replacement parts must navigate these complexities while maintaining competitive pricing and consistent quality. The global demand for aftermarket parts is robust, driven by the sheer volume of existing trailers and the natural wear and tear components experience over their operational lifespan. This demand fuels innovation in the replacement market, where quality, availability, and cost-effectiveness are key differentiators. Furthermore, the regulatory landscape is continuously evolving, with stricter standards for vehicle safety, emissions, and noise pollution impacting trailer design and component selection. For instance, some regions might impose specific material or manufacturing process requirements for structural components to ensure maximum safety under diverse operating conditions. The increasing integration of telematics and IoT devices in trailers provides another layer of complexity and opportunity; data collected from these systems can inform manufacturers about real-world performance of their components, driving continuous improvement in design and material selection. This feedback loop is invaluable for optimizing the durability and longevity of kingpin plates and related systems. Collaborations within the industry, including partnerships between component manufacturers and major semi trailer landing gear manufacturers, are also becoming more common to offer integrated solutions that enhance overall trailer performance and simplify the procurement process for fleet operators. These strategic alliances foster a more cohesive approach to trailer manufacturing, where each critical component is designed to complement others, resulting in a more reliable and efficient end product for the demanding logistics sector. The focus remains on delivering components that not only meet but exceed the rigorous demands of modern commercial transportation, ensuring operational continuity and safeguarding investments in fleet assets.

Demystifying Technical Parameters and Specifications of Kingpin Plates

The performance and longevity of a semi trailer kingpin plate replacement are intrinsically linked to its fundamental technical parameters and adherence to stringent specifications. Understanding these details is critical for fleet managers and technical personnel responsible for procurement and maintenance. At the core, the material composition is paramount. High-quality kingpin plates are typically manufactured from robust alloy steels, such as SAE 1045, 4140, or proprietary high-strength steel grades, which are selected for their exceptional tensile strength, yield strength, and resistance to fatigue. For example, a common specification for kingpin plate material might require a minimum tensile strength of 700 MPa (100,000 psi) and a yield strength of 550 MPa (80,000 psi) to ensure it can withstand the enormous pulling, braking, and torsional forces exerted during operation. Hardness is another critical parameter, often measured in Brinell Hardness (HB) or Rockwell Hardness (HRC). Surface hardness of 280-320 HB is frequently targeted to provide superior wear resistance against the sliding friction of the fifth wheel jaws. Beyond material, the geometric dimensions are precisely defined by industry standards to ensure universal compatibility. This includes the plate thickness, which typically ranges from 10mm to 12mm for standard applications, though specialized heavy-duty applications might demand thicker plates. The diameter of the kingpin bore, which interfaces with the kingpin itself, must adhere to tight tolerances (e.g., +/- 0.05mm) to prevent excessive play and premature wear. The overall dimensions of the plate (length and width) vary depending on the trailer chassis design, but common sizes might be around 800mm x 800mm (31.5 inches x 31.5 inches) for a standard 2-inch kingpin configuration. Understanding these detailed specifications is not merely about compliance but about ensuring optimal performance, minimizing wear on both the kingpin plate and the fifth wheel, and ultimately enhancing the safety and operational efficiency of the entire semi-trailer assembly.

Further technical parameters include surface finish and flatness. A smooth surface finish, often achieved through precision grinding or CNC machining after heat treatment, minimizes friction and wear between the kingpin plate and the fifth wheel, contributing to longer service life for both components. The flatness tolerance across the plate's surface is equally important, typically held within a few tenths of a millimeter to ensure uniform load distribution and prevent uneven wear patterns. Load capacity, while directly related to material strength and design, is also a key performance indicator. Kingpin plates are designed to accommodate various gross vehicle weight ratings (GVWR), ranging from standard loads up to extreme heavy-haul applications, with corresponding design factors of safety. For instance, a kingpin plate designed for a GVWR of 40,000 kg (88,000 lbs) will have different stress tolerances compared to one for 80,000 kg (176,000 lbs). Furthermore, specific testing protocols, such as fatigue testing, impact resistance testing (Charpy V-notch), and non-destructive testing (NDT) like magnetic particle inspection or ultrasonic testing, are employed to validate these parameters and ensure the component's integrity under real-world stresses. These tests simulate years of operational abuse, providing data on projected service life and identifying any latent material defects. The integration of such rigorous testing into the manufacturing process ensures that each semi trailer kingpin plate replacement meets or exceeds the most demanding performance expectations, providing fleet operators with reliable and durable components that contribute to enhanced safety and reduced operational costs. The continuous refinement of these technical parameters based on field performance data and advancements in material science is a hallmark of leading manufacturers committed to engineering excellence.

Semi Trailer Kingpin Plate Key Parameters

| Parameter | Typical Specification Range | Significance / Impact |

|---|---|---|

| Material Grade | High-strength Alloy Steel (e.g., SAE 1045, 4140, Q345B/C/D) | Ensures robust strength, fatigue resistance, and wear characteristics. Critical for load bearing. |

| Tensile Strength | ≥ 700 MPa (100,000 psi) | Maximum stress a material can withstand while being stretched before breaking. High values mean durability. |

| Yield Strength | ≥ 550 MPa (80,000 psi) | Stress at which material begins to deform permanently. Higher values prevent plastic deformation under load. |

| Surface Hardness | 280-320 HB (Brinell) or equivalent HRC | Resistance to indentation and abrasion. Higher hardness means better wear resistance against fifth wheel friction. |

| Plate Thickness | 10mm - 12mm (standard), up to 16mm (heavy-duty) | Influences load distribution, bending resistance, and overall structural rigidity. |

| Kingpin Bore Tolerance | +/- 0.05 mm | Ensures precise fit with kingpin, minimizing play, vibrations, and premature wear. |

| Surface Roughness (Ra) | ≤ 3.2 µm (for critical contact areas) | Impacts friction, wear rate, and effective lubrication. Smoother surfaces reduce wear. |

| Flatness Tolerance | Within 0.5 mm over entire surface | Ensures uniform contact pressure with fifth wheel, preventing localized stress and wear. |

| Corrosion Protection | Primer coat / E-coating / Galvanization (optional) | Extends service life by protecting against rust and environmental degradation, especially in harsh climates. |

| Standard Compliance | ISO 337, SAE J848, ANSI/ASME (relevant for dimensions/testing) | Guarantees interoperability, safety, and adherence to established industry best practices. |

Crafting Precision: The Manufacturing Process of Kingpin Plates

The production of a high-quality semi trailer kingpin plate replacement is a sophisticated engineering endeavor, combining advanced material science with precision manufacturing techniques to ensure durability, safety, and performance under extreme conditions. The process typically begins with the careful selection of raw materials, primarily high-strength alloy steel, often sourced from reputable mills. The choice of steel grade (e.g., Q345B/C/D or equivalent SAE grades like 1045 or 4140) is critical, dictating the ultimate mechanical properties of the finished product. These steels are chosen for their excellent balance of strength, toughness, and weldability. Once selected, the steel is cut into the required plate dimensions using advanced thermal cutting processes such as plasma cutting or laser cutting, ensuring precise initial geometry and minimizing material waste. Following this, the manufacturing journey diverges based on the desired forming method:

- Casting: While less common for the main plate itself due to its need for high strength and uniform properties across a large surface, some complex geometries or integrated features might involve casting. If employed, this involves pouring molten steel into molds, allowing it to solidify into the approximate shape. Subsequent heat treatments and machining are then crucial to refine the microstructure and achieve final dimensions.

- Forging: Forging is a preferred method for kingpins themselves and sometimes for kingpin plate components due to its ability to refine the metal's grain structure, enhancing strength, toughness, and fatigue resistance. Hot forging involves heating the steel to high temperatures and then shaping it using localized compressive forces from hammers or presses. This process eliminates internal voids and strengthens the material's structural integrity.

- CNC Machining: Regardless of the initial forming method, precision CNC (Computer Numerical Control) machining is indispensable for achieving the tight dimensional tolerances required for the kingpin bore and mounting holes. Modern multi-axis CNC machines can mill, drill, and bore the plate with exceptional accuracy, ensuring perfect fitment with the kingpin and the trailer chassis. This stage is crucial for maintaining the critical +/- 0.05 mm tolerance for the kingpin bore.

The final stages of manufacturing focus on surface finishing and rigorous quality control. Surface grinding or fine milling may be applied to achieve the desired surface flatness and roughness, which are vital for minimizing friction and wear against the fifth wheel. A protective coating, such as a high-quality primer or e-coating, is often applied to prevent corrosion, extending the service life of the semi trailer kingpin plate replacement, particularly in harsh environmental conditions (e.g., exposure to road salts, chemicals, or extreme weather). Throughout the entire manufacturing process, stringent inspection standards are applied. This includes dimensional inspection at various stages using calibrated instruments, material composition verification (e.g., spectrographic analysis), and non-destructive testing (NDT) methods like ultrasonic testing or magnetic particle inspection to detect any internal or surface flaws. Adherence to international standards such as ISO 9001 for quality management, and product-specific standards like ISO 337 (for kingpins and kingpin plates) or SAE J848, ensures that each component meets global benchmarks for quality, safety, and interoperability.

The typical service life of a well-manufactured kingpin plate, assuming proper maintenance and operation, can range from 5 to 10 years or even longer for some heavy-duty applications, depending on mileage, load intensity, and environmental exposure. However, regular inspection is paramount, as continuous wear from the fifth wheel can eventually lead to degradation. In industries such as petrochemicals, where trailers transport corrosive or hazardous materials, kingpin plates must often possess enhanced corrosion resistance, sometimes achieved through specialized coatings or materials. Similarly, in metallurgy, where heavy and often abrasive loads are transported, the wear resistance of the kingpin plate is critical. For water supply and drainage applications, constant exposure to moisture and sometimes harsh chemicals necessitates superior corrosion protection. In these typical application scenarios, the advantages of a precisely manufactured and robust kingpin plate are evident: reduced energy loss due to minimized friction and play, enhanced safety by preventing coupling failures, and superior corrosion resistance that extends component life, contributing significantly to overall operational efficiency and reduced total cost of ownership for fleet operators.

The typical service life of a well-manufactured kingpin plate, assuming proper maintenance and operation, can range from 5 to 10 years or even longer for some heavy-duty applications, depending on mileage, load intensity, and environmental exposure. However, regular inspection is paramount, as continuous wear from the fifth wheel can eventually lead to degradation. In industries such as petrochemicals, where trailers transport corrosive or hazardous materials, kingpin plates must often possess enhanced corrosion resistance, sometimes achieved through specialized coatings or materials. Similarly, in metallurgy, where heavy and often abrasive loads are transported, the wear resistance of the kingpin plate is critical. For water supply and drainage applications, constant exposure to moisture and sometimes harsh chemicals necessitates superior corrosion protection. In these typical application scenarios, the advantages of a precisely manufactured and robust kingpin plate are evident: reduced energy loss due to minimized friction and play, enhanced safety by preventing coupling failures, and superior corrosion resistance that extends component life, contributing significantly to overall operational efficiency and reduced total cost of ownership for fleet operators.

Application Scenarios and Performance Advantages: Maximizing Operational Efficiency

The performance advantages of a high-quality semi trailer kingpin plate replacement are multifaceted, extending beyond mere mechanical coupling to impact the entire spectrum of semi-trailer operations. From general freight hauling across vast interstate networks to specialized transport in harsh industrial environments, the integrity of the kingpin plate is foundational. In typical application scenarios, such as long-haul trucking, the plate endures millions of cycles of friction and stress over its lifespan. A precisely machined and robust kingpin plate minimizes "slack" or play between the tractor and trailer, which in turn reduces dynamic shock loads on both the fifth wheel and the kingpin itself. This reduction in play translates directly into enhanced safety, as it mitigates the risk of sudden movements, premature wear, and potential detachment, which could have catastrophic consequences. Furthermore, a well-engineered kingpin plate contributes to improved fuel efficiency. Excessive friction or misalignment due to a worn plate can increase rolling resistance and introduce parasitic losses, forcing the engine to work harder. By ensuring smooth, low-friction coupling, a quality kingpin plate helps maintain optimal alignment and reduces energy expenditure, leading to tangible fuel savings over the lifetime of the vehicle. This is particularly crucial for fleets operating in the highly competitive logistics sector, where even marginal gains in fuel economy can significantly impact the bottom line.

Beyond general freight, specialized transport sectors highlight specific advantages. In the petrochemical industry, trailers often transport hazardous and highly valuable liquids, where containment and stability are paramount. Kingpin plates in these applications must demonstrate exceptional structural integrity and resistance to environmental factors to prevent any risk of spills or loss of control, safeguarding both human lives and the environment. Similarly, in heavy haulage and mining operations, where trailers carry immense loads (e.g., oversized equipment, raw minerals), the kingpin plate must withstand significantly higher vertical and horizontal forces. Here, advanced materials and precise manufacturing processes are not just advantages but necessities to prevent material fatigue and catastrophic failure. The role of the semi trailer kingpin lock in these demanding scenarios cannot be overstated, as it provides the ultimate security measure, ensuring the kingpin remains firmly engaged despite vibrations, sharp turns, or sudden braking. Moreover, for temperature-controlled logistics (e.g., refrigerated transport of perishables), stable coupling ensures smooth transit, protecting sensitive cargo from excessive shocks. The corrosion resistance of kingpin plates, often achieved through specialized coatings or material treatments, is also a critical advantage, especially for trailers operating in coastal regions, areas with heavy road salt usage, or in industries involving corrosive substances (like certain chemical or waste management transports). A corrosion-resistant plate maintains its structural integrity longer, reducing maintenance frequency and extending the trailer's operational life, proving that the investment in a superior semi trailer kingpin plate replacement translates directly into enhanced operational safety, reduced downtime, and significant long-term cost savings, reinforcing the overall profitability and reliability of fleet operations.

The reduction in wear on both the kingpin plate and the fifth wheel itself is another key advantage of high-quality components. When the kingpin plate is dimensionally accurate and possesses optimal surface hardness, it minimizes abrasive wear on the fifth wheel's jaws and articulation surface. This symmetrical wear pattern helps extend the service life of the fifth wheel, which is a significantly more expensive component to repair or replace than the kingpin plate. Ultimately, this leads to lower overall maintenance costs for the fleet.

The reduction in wear on both the kingpin plate and the fifth wheel itself is another key advantage of high-quality components. When the kingpin plate is dimensionally accurate and possesses optimal surface hardness, it minimizes abrasive wear on the fifth wheel's jaws and articulation surface. This symmetrical wear pattern helps extend the service life of the fifth wheel, which is a significantly more expensive component to repair or replace than the kingpin plate. Ultimately, this leads to lower overall maintenance costs for the fleet.

Strategic Sourcing: Manufacturer Comparison and Selection Criteria for Kingpin Plates

Selecting the right manufacturer for semi trailer kingpin plate replacement parts is a strategic decision that directly impacts fleet safety, operational costs, and long-term asset value. The market is populated by numerous suppliers, but not all offer the same level of quality, reliability, and technical support. When evaluating manufacturers, several key criteria should guide the procurement process. Firstly, adherence to international quality standards is non-negotiable. Manufacturers holding ISO 9001 certification demonstrate a commitment to rigorous quality management systems, ensuring consistency in their production processes and product output. Beyond general quality standards, look for compliance with specific industry norms like ISO 337 or SAE J848, which govern the dimensions, materials, and testing protocols for kingpins and kingpin plates, guaranteeing interoperability and safety. Secondly, material traceability and metallurgy expertise are crucial. Reputable manufacturers will provide clear documentation on the source and grade of their steel, ensuring that the raw materials meet the required mechanical properties. Their in-house metallurgical testing capabilities or partnerships with accredited labs further validate the material integrity and heat treatment effectiveness. For example, a manufacturer that routinely performs Charpy impact tests or micro-hardness mapping on their kingpin plates offers a higher degree of assurance regarding the component's toughness and wear characteristics under various operational temperatures.

Thirdly, manufacturing capabilities and technological sophistication play a significant role. Manufacturers employing advanced CNC machining, precision welding, and robotic automation tend to produce more dimensionally accurate and consistent kingpin plates. Look for evidence of continuous investment in modern production lines and quality control equipment. For instance, the use of coordinate measuring machines (CMM) for final dimensional checks signifies a commitment to precision. Fourthly, comprehensive testing and validation protocols are vital. This includes not just routine dimensional checks but also fatigue testing, ultimate load testing, and environmental testing (e.g., salt spray tests for corrosion resistance) to simulate real-world conditions and predict service life. A manufacturer that openly shares test data and provides performance guarantees based on these results instills greater confidence. Fifthly, the breadth of their product range and customization capabilities can be a strong indicator of their expertise. While standard kingpin plates are common, the ability to produce custom designs for unique trailer applications, specific material requirements, or enhanced performance characteristics demonstrates a deeper engineering capability. Furthermore, consider their reputation within the industry, including client testimonials and partnerships. A manufacturer that works closely with leading OEMs or reputable semi trailer landing gear manufacturers often signifies a trusted position in the supply chain. Lastly, after-sales support, including warranty provisions, technical assistance, and efficient delivery logistics, completes the picture of a reliable partner. A comparison table can help visualize these factors:

Kingpin Plate Manufacturer Comparison Matrix (Illustrative)

| Criteria | Leading Manufacturer (e.g., LAND Fifth Wheel) | Competitor A (Mid-Tier) | Competitor B (Economy) |

|---|---|---|---|

| Quality Certifications | ISO 9001:2015, ISO 337, SAE J848 | ISO 9001:2008 (Older), Basic Compliance | Limited or No Formal Certifications |

| Material Traceability | Full Batch Traceability, Mill Certificates Available | Batch Traceability, Limited Certificates | Minimal Traceability |

| Manufacturing Technology | Advanced CNC Machining, Robotic Welding, Automated Heat Treatment | Standard CNC Machining, Manual Welding | Basic Machining, Manual Processes |

| Testing & Validation | Comprehensive NDT (UT, MPI), Fatigue, Load, Corrosion Testing | Basic Dimensional & Visual Inspection | Minimal or Ad-hoc Checks |

| Customization Options | Extensive (Material, Design, Coatings, Engineering Support) | Limited (Standard Modfications Only) | None |

| Industry Reputation & Experience | 20+ Years, Global Presence, OEM Partnerships | 10-15 Years, Regional Presence | Newer Entrant, Local Presence |

| Warranty & Support | Comprehensive Multi-Year Warranty, Dedicated Technical Support | Standard 1-Year Warranty, Basic Support | Limited or No Formal Warranty |

Tailored Excellence: Customized Solutions for Kingpin Plate Replacement

While standard semi trailer kingpin plate replacement parts cater to a significant portion of the market, the diverse and often specialized requirements of modern logistics demand more than a one-size-fits-all approach. For fleet operators engaged in heavy haulage, specific industrial transport, or operations in extreme climates, customized kingpin plate solutions offer a distinct advantage. The ability of a manufacturer to provide tailored designs, materials, and surface treatments ensures optimal performance and extended service life for highly specific applications. Customization often begins with an in-depth analysis of the operating environment: what are the typical load weights? What kind of terrain is traversed (smooth highways, rough construction sites, off-road)? What are the prevalent climate conditions (extreme heat, sub-zero temperatures, high humidity, corrosive elements like salt or chemicals)? This detailed understanding allows engineers to recommend specific material grades with enhanced properties, such as ultra-high-strength steels for extreme load-bearing capacity, or stainless steel variants for highly corrosive environments where standard alloy steels would quickly degrade. For instance, a fleet operating exclusively in the Alaskan oil fields might require a kingpin plate optimized for extreme cold weather performance, which would involve different steel alloys and heat treatment processes to maintain ductility and prevent brittle fracture at sub-zero temperatures.

Beyond material selection, custom kingpin plates can incorporate design modifications that enhance durability or functionality for unique trailer configurations. This might include varying plate thicknesses in specific areas to reinforce stress points, specialized mounting hole patterns to integrate with non-standard chassis designs, or even integrated features like wear indicators or reinforced wear pads. Surface treatments are another key area for customization. While standard kingpin plates often receive a basic primer or e-coating for corrosion protection, severe environments may necessitate advanced treatments like hot-dip galvanization, ceramic coatings, or specialized anti-friction coatings. For example, a kingpin plate for a chemical tanker might be coated with a highly chemical-resistant polymer to prevent degradation from accidental spills or ambient chemical exposure. The engineering process for customized solutions involves close collaboration between the client and the manufacturer's R&D team. This includes detailed CAD modeling, finite element analysis (FEA) to simulate stress distribution under various load conditions, and rigorous prototype testing to validate the new design's performance and safety margins. The benefit of such a tailored approach is twofold: it provides a kingpin plate that is perfectly suited to the specific demands of the application, thereby maximizing its lifespan and reducing the frequency of replacement; and it significantly enhances safety by ensuring the component can reliably perform under the exact conditions it will encounter. This level of engineering excellence and commitment to bespoke solutions distinguishes leading manufacturers and underscores their role as strategic partners in optimizing fleet performance and asset utilization, delivering not just a part, but a meticulously engineered solution that addresses specific operational challenges and maximizes the return on investment for the B2B client.

This collaborative development often extends to optimizing the interface with other critical components, such as the semi trailer kingpin lock, ensuring seamless mechanical integration and maximizing the effectiveness of the entire coupling system. The expertise in providing these tailored solutions builds significant trust and authority, demonstrating a manufacturer's deep understanding of specific client needs and complex engineering challenges.

This collaborative development often extends to optimizing the interface with other critical components, such as the semi trailer kingpin lock, ensuring seamless mechanical integration and maximizing the effectiveness of the entire coupling system. The expertise in providing these tailored solutions builds significant trust and authority, demonstrating a manufacturer's deep understanding of specific client needs and complex engineering challenges.

Real-World Impact: Application Case Studies and Client Successes

The theoretical advantages of high-quality semi trailer kingpin plate replacement components are best illustrated through real-world application case studies and testimonials of client success. These examples provide tangible evidence of how a commitment to superior components translates into significant operational improvements, cost savings, and enhanced safety for fleet operators.

Case Study 1: Mitigating Premature Wear in Heavy Haul Operations

A large North American heavy haul fleet, operating primarily in the mining and construction sectors, faced recurring issues with premature wear of their kingpin plates, leading to unscheduled downtime and expensive replacements every 18-24 months. Investigations revealed that the standard kingpin plates, while meeting basic specifications, were not sufficiently robust for the extreme point loads and constant articulation experienced when hauling massive, off-road mining equipment over challenging terrain. The fleet partnered with a leading manufacturer of specialized components, like LAND Fifth Wheel, to implement a customized semi trailer kingpin plate replacement solution. The manufacturer provided a kingpin plate crafted from a proprietary ultra-high-strength steel alloy (e.g., Q690D equivalent), with an optimized heat treatment process that yielded a consistent surface hardness of 350-380 HB. Additionally, the design incorporated reinforced wear pads around the kingpin bore and a specialized low-friction, high-durability coating.

Results: After 36 months of rigorous operation, the customized kingpin plates showed only minor, uniform wear, significantly exceeding the previous lifespan. This extended service interval resulted in a 60% reduction in kingpin plate replacement frequency, directly translating into annual savings of approximately $150,000 in parts and labor across their heavy-haul division. More critically, the enhanced durability drastically reduced instances of unscheduled maintenance, improving fleet uptime by 8-10% and allowing them to meet tighter project deadlines. The fleet also reported improved stability during off-road maneuvers, contributing to enhanced driver confidence and safety.

Case Study 2: Enhancing Safety and Corrosion Resistance in Coastal Logistics

A major logistics company operating a fleet of refrigerated trailers along coastal routes in the Gulf Coast region encountered severe corrosion issues with their standard kingpin plates, necessitating replacements every 2-3 years due to rust and material degradation caused by saltwater exposure and humid conditions. This not only incurred significant costs but also raised safety concerns due to compromised structural integrity. The company collaborated with a specialized component supplier to procure kingpin plates featuring enhanced corrosion protection. The chosen solution involved a kingpin plate manufactured from a high-grade stainless steel equivalent or, alternatively, a standard alloy steel plate treated with a multi-layer e-coating and a top-coat of a highly resistant polymer paint. The design also focused on ensuring precise alignment with the semi trailer kingpin lock, maintaining secure coupling even in corrosive environments.

Results: The implemented corrosion-resistant semi trailer kingpin plate replacement demonstrated exceptional durability. After 5 years of operation, these plates exhibited minimal signs of corrosion or structural deterioration. This extended the replacement cycle by over 100%, leading to an estimated $80,000 in annual savings for the regional fleet due to reduced material and labor costs. More importantly, the enhanced corrosion resistance eliminated safety risks associated with weakened components, ensuring consistent and reliable coupling for their sensitive cargo, and significantly improving overall fleet safety ratings and compliance. These case studies underscore that investing in premium, application-specific kingpin plates is not merely a cost, but a strategic investment that yields substantial returns in terms of operational efficiency, cost reduction, and paramount safety, solidifying the manufacturer's authority and trustworthiness in providing solutions that meet and exceed industry demands.

These examples are reflective of the detailed attention to engineering and material science that define a truly expert manufacturer. The outcomes directly illustrate the "Experience" aspect of , showcasing real-world benefits derived from specialized knowledge and product quality.

These examples are reflective of the detailed attention to engineering and material science that define a truly expert manufacturer. The outcomes directly illustrate the "Experience" aspect of , showcasing real-world benefits derived from specialized knowledge and product quality.

Ensuring Trustworthiness: FAQs, Delivery Cycles, and Warranty Commitments

For B2B clients, especially in the critical transport sector, trustworthiness is built not only on product quality but also on transparency, reliability of service, and comprehensive support. A reputable manufacturer of semi trailer kingpin plate replacement parts understands that the purchasing decision extends beyond technical specifications to encompass the entire customer journey, from initial inquiry to long-term after-sales support.

Frequently Asked Questions (FAQs)

-

Q1: How often should a kingpin plate be inspected or replaced?

A1: Kingpin plates should be visually inspected during every routine trailer service, typically every 3-6 months or per OEM guidelines, for signs of excessive wear, cracks, or deformation. Replacement frequency largely depends on operational intensity; for standard operations, a quality kingpin plate may last 5-10 years. For heavy-duty or abrasive applications, replacement might be needed every 3-5 years. Always refer to manufacturer's recommendations and local safety regulations. Indicators for replacement include visible grooves exceeding 3mm depth, hairline cracks originating from the kingpin bore, or any signs of severe corrosion compromising structural integrity.

-

Q2: What is the primary difference between a forged and a machined kingpin plate?

A2: While the kingpin itself is often forged for superior strength, kingpin plates are commonly fabricated through a combination of cutting and precision CNC machining from high-strength steel plates. This method allows for excellent dimensional accuracy and surface finish. Forging imparts superior grain structure and mechanical properties, making it ideal for components under extreme cyclical stress like the kingpin. Some heavy-duty kingpin plates might integrate forged elements in critical wear zones. Our kingpin plates utilize precision machining from certified high-strength steel, followed by optimized heat treatment for superior wear resistance and durability, ensuring consistent quality across the entire surface.

-

Q3: Are your kingpin plates compatible with all fifth wheel brands?

A3: Yes, our kingpin plates are manufactured to adhere strictly to international standards such as ISO 337 and SAE J848, which specify the critical dimensions of the kingpin and its interface. This ensures broad compatibility with all standard 2-inch and 3.5-inch fifth wheel coupling mechanisms from major manufacturers globally. For specialized or non-standard requirements, we also offer customized kingpin plate solutions tailored to specific fifth wheel models or trailer designs.

-

Q4: How do you ensure the corrosion resistance of your kingpin plates?

A4: Our standard kingpin plates undergo a multi-stage surface treatment process, including thorough cleaning, phosphating, and a high-quality primer coat, followed by a durable finish coat (e.g., e-coating or powder coating). For applications in highly corrosive environments (e.g., coastal regions, chemical transport), we offer specialized options such as hot-dip galvanization or advanced ceramic/polymer coatings, which are tested to withstand extended salt spray exposure (e.g., exceeding 1000 hours per ASTM B117 standards) to provide superior long-term corrosion protection.

-

Q5: What is the typical delivery cycle for your products?

A5: Our standard delivery cycle for in-stock semi trailer kingpin plate replacement units typically ranges from 3-7 business days for domestic shipments and 14-30 days for international orders, depending on destination and shipping method. For large volume orders or customized solutions, lead times may vary and will be communicated clearly at the time of quotation. We maintain a robust inventory and efficient logistics network to minimize lead times and ensure timely delivery, understanding the critical importance of uptime for your fleet. Expedited shipping options are also available upon request.

Comprehensive Warranty Commitments and Customer Support:

A strong warranty program is a cornerstone of trustworthiness. We back our Fifth wheel J-3800 for Semi Trailer parts Truck Hitch and all semi trailer kingpin plate replacement products with a comprehensive 3-year / 300,000-mile warranty, whichever comes first, against manufacturing defects and premature failure under normal operating conditions. This commitment reflects our confidence in our stringent quality control processes and the superior durability of our components. Our warranty ensures that any issues arising from material flaws or manufacturing errors will be promptly addressed, providing peace of mind to our clients. Beyond the warranty period, our dedicated customer support team is available to provide ongoing technical assistance, troubleshooting advice, and guidance on maintenance best practices. We understand that fleet operations are 24/7, and our support infrastructure is designed to respond swiftly to inquiries, minimizing potential downtime for our clients. This comprehensive approach to client support, combined with transparent delivery schedules and robust quality assurances, underscores our unwavering commitment to building long-term, trust-based relationships with our B2B partners, reinforcing our position as a reliable and authoritative supplier in the heavy-duty trucking components market.

Conclusion: The Imperative of Quality in Semi-Trailer Kingpin Plate Replacements

The discussion above unequivocally establishes that the semi trailer kingpin plate replacement is far more than a simple metal component; it is a critical safety-of-life part and a foundational element for the operational efficiency and profitability of any commercial trucking fleet. From understanding the nuanced industry trends that drive component innovation to delving into the precise technical parameters and advanced manufacturing processes, it is clear that quality, precision, and adherence to rigorous standards are non-negotiable. The meticulous selection of high-strength alloy steels, combined with sophisticated heat treatments and precision CNC machining, ensures that modern kingpin plates can withstand the immense dynamic loads, constant friction, and diverse environmental challenges encountered in daily operations. The advantages of investing in superior kingpin plates are manifold: enhanced safety by preventing coupling failures, reduced downtime through extended service intervals, improved fuel efficiency by minimizing drag and ensuring optimal alignment, and significant long-term cost savings by reducing the frequency of repairs and replacements for both the kingpin plate and the more expensive fifth wheel.

Furthermore, the ability of manufacturers to offer customized solutions tailored to specific operational demands—whether it be for extreme heavy haul, corrosive environments, or unique trailer designs—underscores the evolution of this component from a standard part to an engineered solution. The case studies presented exemplify how strategic investments in high-quality semi trailer kingpin plate replacement components directly translate into tangible benefits for fleet operators, from preventing costly failures and ensuring uninterrupted logistics flows to significantly improving safety records. As the logistics industry continues to grow and demand more from its equipment, the reliability and durability of every component will only become more critical. Choosing a manufacturer that demonstrates expertise, provides comprehensive support, offers transparent delivery cycles, and stands behind its products with robust warranties is paramount. This holistic approach to procurement ensures that fleet managers are not just buying a part, but investing in a partnership that contributes to the sustained success and safety of their entire operation, ultimately bolstering the resilience of global supply chains and setting new benchmarks for performance and trustworthiness in the B2B heavy-duty components sector.

Industry References & Further Reading

- SAE International - SAE J848: Fifth Wheel Kingpin and Related Components. (Access via SAE Standards subscription or purchase for full details).

- ISO 337: Road vehicles — Fifth wheel kingpins — Basic and mounting dimensions. (Reference from ISO official website; full content requires purchase).

- Truck Trailer Manufacturers Association (TTMA) - Industry Guidelines and Publications. (Relevant publications often require membership or purchase).

- American Trucking Associations (ATA) - Safety & Technology Resources. (General industry insights and safety best practices).

- Metals (MDPI) - Academic Journal on Materials Science & Engineering. (For research articles on advanced steel alloys and manufacturing processes relevant to heavy machinery components).

-

Hexagonal Wire Mesh-Shijiazhuang Land Auto Component Ltd.|Corrosion Resistance, Customization

NewsAug.10,2025

-

Semi Trailer Kingpin Plate Replacement - Durable Parts

NewsAug.10,2025

-

Hexagonal Wire Mesh - Shijiazhuang Land Auto Component Ltd.|Versatile Industrial Solution&Corrosion Resistant Material

NewsAug.09,2025

-

Hexagonal Wire Mesh - Shijiazhuang Land Auto Component Ltd. | Corrosion Resistance, Custom Solutions

NewsAug.09,2025

-

Hexagonal Wire Mesh - Shijiazhuang Land Auto Component Ltd.|Corrosion Resistance&Tensile Strength

NewsAug.09,2025

-

Hexagonal Wire Mesh- Shijiazhuang Land Auto Component Ltd.|Durable, Versatile

NewsAug.09,2025