ජූලි . 25, 2025 01:01 Back to list

High-Strength Semi Trailer Kingpin Plate Replacement for Secure Transport

As the freight and logistics industry scales to new highs, the structural safety and performance of semi trailers remain indispensable. At the heart of every semi trailer’s attachment to its tractor lies the kingpin plate and fifth wheel system, pivotal in ensuring mechanical reliability across robust driving scenarios. This comprehensive guide dives into the complexities of semi trailer kingpin plate replacement solutions, explores the influence of kingpin locks and landing gear manufacturing, and highlights breakthrough products by Shijiazhuang Land Auto Component Ltd. (Official Website), a global leader in the sector.

Shijiazhuang Land Auto Component Ltd.

📍 Address: Shijiazhuang City, Hebei Province CHINA 🌐 Website: www.landfifthwheel.com 📞 Tel: +86 13091005279 | 13091005279 ✉ Email: info@land-d.cn

📍 Address: Shijiazhuang City, Hebei Province CHINA 🌐 Website: www.landfifthwheel.com 📞 Tel: +86 13091005279 | 13091005279 ✉ Email: info@land-d.cn

Understanding Semi Trailer Kingpin Plate Replacement

The semi trailer kingpin plate replacement process is crucial for ongoing vehicle safety and compliance. As the kingpin is the primary connection between the trailer and tractor, plate wear or deformation can endanger roadworthiness and fleet commercial reliability. Industry trends indicate an increasing demand for semi trailer kingpin lock technology and automated semi trailer landing gear manufacturers innovation, ensuring quick, safe repairs and minimal downtime.

Below is a technical parameter summary for semi trailer kingpin plate replacement based on recent industrial data.

Below is a technical parameter summary for semi trailer kingpin plate replacement based on recent industrial data.

| Parameter | Standard Value | Tolerance | Industry Reference |

|---|---|---|---|

| Kingpin Diameter | 2"/3.5" (50.8mm/88.9mm) | ±0.02mm | FHWA Guidelines |

| Plate Thickness | 12-20mm | ±1.0mm | TruckScience |

| Material Specification | Q345B/S355JR steel | --- | JPE Journal |

| Kingpin Hardness | HB320-380 | ±15HB | Trailer Body Builders |

| Bolt Pattern | 6/8/10 holes, diameter 20-24mm | ±0.5mm | Fleet Owner |

| Load Rating | 18-35 Tons | --- | SEMA |

| Corrosion Coating | Zinc/Galvanized | --- | Tribology in Industry |

Application Scenarios for Kingpin Plate Replacement and Fifth Wheel Integration

Semi trailer kingpin plate replacement plays a vital role in long-haul logistics, mining, container111 transport, and hazardous cargo movements. In every application, plate integrity and robust kingpin connection directly influence safety and efficiency. New-generation semi trailer kingpin locks further prevent accidental uncoupling, essential for security-sensitive freight. Moreover, growth in advanced semi trailer landing gear manufacturers ensures stability during loading, parking, and maintenance cycles.

A breakthrough in this space is the Fifth wheel J-3800 for Semi Trailer parts Truck Hitch, engineered by Shijiazhuang Land Auto Component Ltd.. Boasting ultra-large tonnage loading and four-way swinging, it adapts across the most challenging logistics terrain, maximizing fleet uptime and safety.

A breakthrough in this space is the Fifth wheel J-3800 for Semi Trailer parts Truck Hitch, engineered by Shijiazhuang Land Auto Component Ltd.. Boasting ultra-large tonnage loading and four-way swinging, it adapts across the most challenging logistics terrain, maximizing fleet uptime and safety.

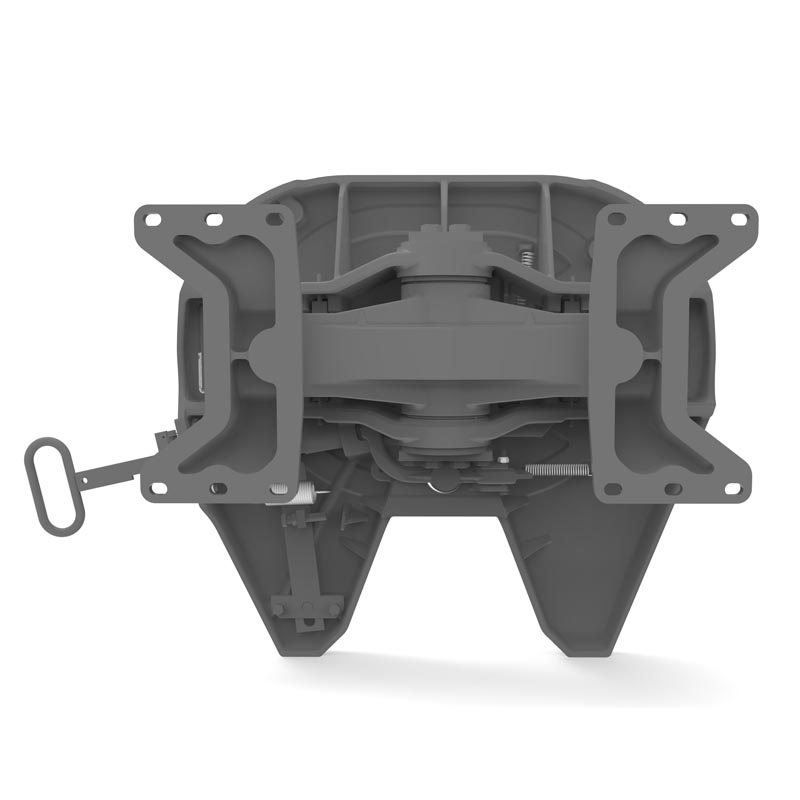

Spotlight Product: Fifth wheel J-3800 for Semi Trailer parts Truck Hitch

Fifth wheel J-3800 is purpose-built for carriers demanding ultra-high load capacity and maximum articulation.

Product Profile: Ultra-large tonnage loading capacity, four-way swinging, and adaptability to a variety of complex road conditions.

Product Profile: Ultra-large tonnage loading capacity, four-way swinging, and adaptability to a variety of complex road conditions.

- Model: J-3800

- Max Load: 36,000 kg

- Vertical Load: 20,000 kg

- Swivel Degree: 4-way, ±7°

- Material: High-strength alloy steel (Q345B/S355JR)

- Corrosion Protection: Hot-dip galvanized finish

- Operating Temperature: -40℃ to +60℃

- Mounting: Multi-hole bolt pattern for universal fit

- Application: Container, mining, and international logistics fleets

Industry Trends: Semi Trailer Kingpin Plate, Lock Security, and Landing Gear Innovations

- Kingpin Plate Materials: Market shifts toward hardened alloy (Q345B, S355JR) and surface treatments like galvanizing for prolonged lifecycle (see Tribology in Industry).

- Intelligent Kingpin Locks: Surge in demand for electronic and IoT-enabled locks that deliver real-time fleet security metrics and immobility assurance (Trailer Body Builders).

- Automated Landing Gear: Adaptive, hydraulic landing gear systems produced by leading semi trailer landing gear manufacturers enable fast, safe trailer detachment and stabilization under variable loads (Fleet Owner).

- Digital Maintenance Tracking: Implementation of RFID and telematics for kingpin, plate, and fifth wheel lifecycle management—shifting from time-based to condition-based replacement cycles.

- Modular Fifth Wheel Systems: Modularity accommodates a wide spectrum of trailer types, supporting easy, fast semi trailer kingpin plate replacement.

Expert FAQ: Semi Trailer Kingpin Plate Replacement and Fifth Wheel Technology

Frequently Asked Technical Questions

- 1. What material is typically used for kingpin plates? Kingpin plates predominantly use Q345B or S355JR alloy steel due to exceptional hardness and fatigue resistance (JPE Journal).

- 2. What are industry standard specifications for kingpin size? Industry standards, like AAR and ISO 337, define 2" (50.8mm) and 3.5" (88.9mm) as the main kingpin diameters. Precise machining ensures secure fits (TruckScience).

- 3. How often should semi trailer kingpin plate replacement be performed? Recommendations suggest every 5-7 years or 500,000+ km, but actual replacement depends on wear indicators or crack detection (FHWA).

- 4. What are the key features of the Fifth wheel J-3800 compared to traditional fifth wheels? J-3800 supports higher load (36T), 4-way swinging ±7°, high-temperature resilience, and galvanized anti-corrosion.

- 5. How do modern semi trailer kingpin locks enhance cargo security? Modern locks feature high-tensile materials, tamper alerts, and can be integrated with telematics for real-time monitoring.

- 6. What mounting standards do leading semi trailer landing gear manufacturers support? Manufacturers align with ISO, DOT, and UNECE mounting patterns, supporting fast retrofits and universal compatibility.

- 7. What installation precautions are vital for semi trailer kingpin plate replacement? Critical steps: degreasing, correct torque on bolts (per OEM values), verifying plate alignment, and post-install NDT inspection.

Why Choose Shijiazhuang Land Auto Component Ltd.?

Shijiazhuang Land Auto Component Ltd. stands at the forefront of semi trailer kingpin plate replacement, kingpin locks, and landing gear innovations, backed by over two decades of relentless engineering R&D. With advanced CNC manufacturing, global certifications (ISO/TS), and reference installations in over 50 countries, Land Auto upholds the industry’s highest standards.

For customized consulting, product inquiries, or technical support, please contact our team:

Tel: +86 13091005279 | Email: info@land-d.cn

Website: www.landfifthwheel.com

For customized consulting, product inquiries, or technical support, please contact our team:

Tel: +86 13091005279 | Email: info@land-d.cn

Website: www.landfifthwheel.com

Conclusion and Industry References

The efficiency and safety of logistics hinge on selecting the right components—be it state-of-the-art kingpin plates, intelligent kingpin locks, or robust landing gear. The advancement in technologies for semi trailer kingpin plate replacement and the premier capabilities of products like the Fifth wheel J-3800 set new industry benchmarks for reliability and performance.

For further authoritative reading and industry best practices, refer to:

For further authoritative reading and industry best practices, refer to:

- Federal Highway Administration (FHWA): Trailer Safety

- TruckScience: Kingpin Positioning in Trailer Design

- Tribology in Industry (Elsevier)

- Trailer Body Builders: Spec'ing the Right Kingpin

- Fleet Owner: Complete Fifth Wheel Maintenance Guide

- Journal of Processing Engineering: Kingpin Material Science

- SEMA: Semi-Trailer Safety Best Practice

Latest news

-

American Type Welding Series Suspension - Durable Industrial Solution

NewsJul.26,2025

-

High-Strength Semi Trailer Kingpin Plate Replacement for Secure Transport

NewsJul.25,2025

-

Holland Fifth Wheel Rebuild Kit for Heavy-Duty Trucks – Durable & Reliable

NewsJul.24,2025

-

JOST TAPE Fifth Wheel 37C Repair Kits-Shijiazhuang Land Auto Component Ltd.|Durable Performance&Reliable Solutions

NewsJul.23,2025

-

Holland Fifth Wheel Rebuild Kit – Durable & Easy Replacement Parts

NewsJul.23,2025

-

Premium 5th Wheel Bumper Kit for Safe Towing & Easy Installation

NewsJul.22,2025